|

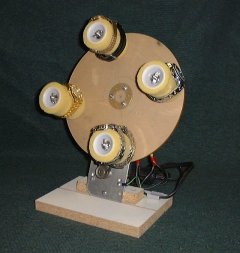

| Junk Box Watch Winder Version II |

|

| Updated 02-18-2002 |

| See Steve's version of the

winder |

| Newest Modifications to this Winder |

| The original

"Junk Box Watch Winder" worked well for it's

purpose of winding watches, but due to my use of a

barbecue rotisserie motor the life of the winder was

short. Within 3 months the motor had destroyed itself due to the stresses of rotating both the watch disc and the rollers in order to achieve enough rotation to keep the watches wound. The barbecue motor rotated slowly and a "drive band" was used to rub against the rollers while the disc rotated. This provided enough velocity to keep the watches wound, but was really noisy and overloaded the motor. Since the original idea worked I decided to use the same principle, but redesign the drive system. This page outlines the modifications to produce Version II. |

| Scrounging

around in my junk box I found a shaded pole gearmotor

with real bronze sleeve bearings. The shaft rotated at 50

R.P.M. which was too fast to keep the watches stable on

the disc. I looked around a little more and found a couple of pulleys and a toothed belt which would give approximately a 50% reduction in shaft speed. The small pulley fit the 5/16" motor shaft perfectly. |