First Back Plate Removal

|

This picture

shows the first of two stainless steel back

plates which must be removed to get to the

mechanism. These plates serve to shield the

electronics, carry gear bearings/pivots, and

act as return springs for the pushers. They

are very accurate precision stampings.

|

| |

|

Second Back Plate

Removal

|

The second

backplate, when removed exposes the flexible

printed circuit board. |

| |

|

Flexible Printed Circuit

Board

|

The flexible

printed circuit board is the "control

center" for the entire watch. It consists of the

Control Integrated Circuit "I", the 32,767 hZ

crystal "C" and alarm

transducer circuitry "P".

This P.C.B. is

similar to that found in cameras and other

electronic instruments. All of the

interconnects are pressure type Gold to Gold

so no soldering is required.

|

| |

|

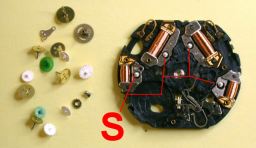

Gears at Last !

|

After the

circuit board is removed the back plate is

the next item to come off. Two more white

nylon cams "S" are turned to

remove the back plate revealing the geartrain

and stepper motors. |

| |

|

Gears and Motors

|

With the back

plate off the geartrain can be removed.

The geartrain consists of:

7 - Brass and Nickel gears.

2 - Hard plastic gears (Green)

5 - White Nylon gears.This watch has 4

stepper motors "S" !

The motors consist of an armature (white dots

that the call out points to) and a coil for

each motor.

|

| |

|

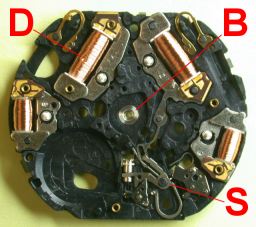

Closeup of Motors

|

The closeup

in this picture shows the steel bushing

"B" for the main

watch hands, a somewhat complex looking

spring "S" which operates

the setting mechanism for the crown, and,

finally the damaged part, a dent in the coil

"D" which must have

been causing the intermittant opertaion. |

| |

|

Conclusion

Far from being a blob of plastic with a

battery and motor, quartz watches are quite

impressive when you consider the number of

technologies involved in their production.

Everything from precision diecasting to

miniature motors to standard screw machine

fabrication is involved.You won't find any

"Old World Craftsmanship" here,

just modern manufacturing of the type that

made Japanese cars and cameras some of the

best in the world.

|