Mining and metallurgy

The use of metals was a very important factor for the development of the technology. When and how begins this development is another historical problem. The ancient things that we found and the indications according them don't always match the history, as we know it.

lathe for metals

Firstly: what is a lathe?

A lathe is a machine tool that removes unwanted material from a cylindrical work piece by rotating it against a cutting tool. Common operations include shaping, boring, and threading.

But how ancient can a lathe be?

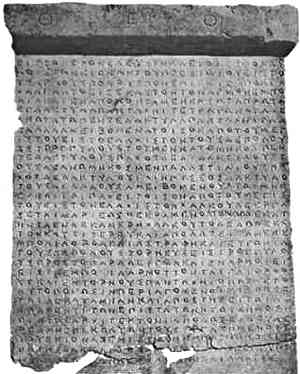

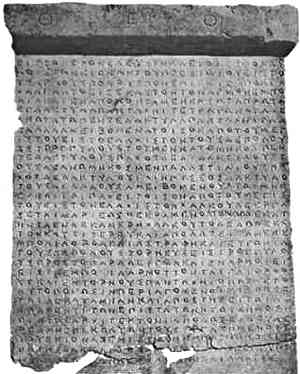

In a marble plate found at Elefsis (near Athens) there is an order for some metal parts of specific quality and specific shape and cylindrical poles. Also there is a specification in the text for lathe to be used for metals and not for wood or hardened clay.

In a marble plate found at Elefsis (near Athens) there is an order for some metal parts of specific quality and specific shape and cylindrical poles. Also there is a specification in the text for lathe to be used for metals and not for wood or hardened clay.

From this we can conclude: They knew how to use and make sharp material harder than copper and iron. They were also using lathes for wood and ceramics. The ceramics seem too delicate to me to be used in a lathe but the technicians of this time probably knew better!

The marble plate is made about 400 B.C. So the invention of the Lathe may be 100 or 150 years older!

elaboration of iron

In the sixth century B.C. Glaukos from Hios managed to join iron.

Also at the village 'Steno' 6 km east of Tripolis there is found metal furnaces from 2500-2200 B.C.!

It is not sure when iron appears for the first time in Greece.

At Mycenae and Pylos have been found iron rings made from iron mixed with nickel to make it stainless. These rings are from 1500 B.C. from a time period that we knew as copper period!

We find a wider use of iron on tools and weapons after 1200 B.C.

In order to convert the iron to steel it must be heated up to 750 - 900°C in an environment with much carbon. After that the very hot metal has to be soused in water or oil. This creates carbide mixtures making the iron very hard. To make it also more flexible we have to heat it again up to 250-450°C.

An old tradition on metalworking says that in order the hot metal to become as strong as possible should be turned to the north while it was cooling. Did they know that this way the small magnets inside the iron look all the same way making it stronger, or they were just lucky trying it?

We know that iron and steel are easy to rust especially in wet environment. But this didn't happen to the Asoka column. This is an iron column, 9 meters height, which locates to New Delhi of India. It is almost 1600 years old and the way that it became stainless remains unknown.

artistic metallurgy

If we take a good look at the findings from the Minoan period we conclude that these people could easily hammer and smelter metals to make tools and excellent jewellery. The gold jewellers from this period are as difficult to make as the moderns. All these before 1450 B.C. the Minoan civilization stops suddenly probably because of the explosion of Thyra's volcano.

After that we found the next civilization at Mycenae. There we found a lot of metal works too. The most used metal remains the copper with mixtures of tin to make it harder. In the tombs of Mycenae there has been found a lot of jewellery and implements made of gold and silver. The metal workers of this time period already are working without difficulties with the most of the modern techniques that we know today.

With the Greeks, bronze assumed a role of great importance. The technique of solid casting continued being used for small works even after the discovery of hollow casting, traditionally ascribed to Rhoiko, Telekles, and Theodoros, craftsmen from Samos, in the 6th century B.C.. Most of the larger bronzes have disappeared, but the famous Charioteer of Delphi (c.470 B.C.; Delphi Museum) is an outstanding example of the high quality of Greek bronzes.

The Etruscans made extensive use of bronze and were highly skilled in its working. In addition to the manufacture of household furnishings and military accoutrements, the Etruscans used bronze for freestanding works, as in the Capitolian She-Wolf (c.500 B.C.; Palazzo dei Conservatori, Rome).

The Romans made considerable advances in the technical aspects of bronze casting, particularly in the use of prefabricated parts and in methods of joining metals to each other. Bronze was used for various kinds of military equipment, for the decoration of furniture, and for domestic utensils. It was also used for monumental works as noteworthy and subsequently influential in the history of art as the majestic equestrian statue of Marcus Aurelius (AD 161-80) in Rome.

metal alloys

The copper used during the Minoan and Mycenaean period was mixed with tin to become harder. The alloy had also a lighter colour. This alloy is known as bronze.

Another alloy that used much later at the roman period is zinc with copper. Zinc was much cheaper than tin these days and also helped more the flow of the melted metal alloy to difficult shapes. This alloy is not bronze of course.

The temperatures that these alloys require for proper melting are close to 8000C.

Incas were also using some allows of silver and platinum. But platinum melts at 1775°C...!

metal mines

Of course metallurgy needs metals from mines. So mine technology was also used as far as possible.

metallurgical activity from 3000 B.C. has been found near Lavrion, at the place Thorikon. There, an impressive system to clean the mineral from clay was also found. They used a washing system as any mine does, but because they didn't have a lot of water they were recycling it! The washing area was arranged on such a cycle that the used water could return very close to where it started to be cleaned. This way only a few personnel were needed to drop this water again to the higher level. They had also made some cisterns that were insulated to avoid water leaks with material that even today we can't understand what it exactly was!

The mines of Thorikon gave enough silver to Athens to create the miracle that they did. At the time of the victory of Athens over the Persian navy in the sea fight of Salamina the mines were at their peak production at 750 talants each year. This helped to construct 200 new triremes (battle ships) for the Athenians navy!

When the mines on Lavrion had not enough silver Athena soon lost its leading place. Soon after that came the gold mines of Pagaio mountain that made the kingdom of Alexander the great the most powerful in Greece and Macedonia the next Greek leader.

The most impressive fact related to metals is a mine for copper found in Rhodesia and seem to be working before 47.000 years! Another iron mine at Ngouenya Swaziland seems to be 25.000 years old and having hematite (iron like stone).

kilns

At the Greek village Steno 6 km east of Tripolis there have been found kilns for metals from 2500 -2200 B.C. The size and the spread of these kilns is very big, this is a metallurgy centre.

At the Greek island Ikaria at the coast of Kionion at the place Siderocapso has been found a very big kiln for metals. Its diameter is 3.6 meters and its height over 3.4 m. It is build with schist and pegmatite. Internal there is ceramic material that is turned to glass because of the high temperature that went at least up to 800°C.

At the Greek island Ikaria at the coast of Kionion at the place Siderocapso has been found a very big kiln for metals. Its diameter is 3.6 meters and its height over 3.4 m. It is build with schist and pegmatite. Internal there is ceramic material that is turned to glass because of the high temperature that went at least up to 800°C.

At the same island at the place Drakano there has been found the ruins of an iron mine.

At the Menjamor of the Soviet Armenia, professor Korioun Megertzian found an ancient metallurgical factory. Almost 200 kilns found with items of copper, bronze, lead, zink, iron, gold, tin, arsenate, antimony, magnesium and some more. Most metals were imported and there been found 14 different types of bronze, probably according to their use.

There have been also found some nippers made from steel that had kept their shine! But these were only 3.000 years old...!

At the same territory was an observatory, build in three levels and looking south.

gold

Let's take a closer look to the metal that since the beginning of history causes the most troubles to humanity, the gold. It can be found even in the river coasts at a pure form. It can be shaped easily cold or heated. Big advantage is that it can't rust or oxidized.

At the close picture we can see part of a Scythian comb made of gold and decorated with a battle scene. The detail is excellent and it is probably made by Greeks of the same area. Such detail remains unusual even today and we also have to consider that the gold melts at 1100°C. I thing we own a little more respect to the ancient technicians and artists.

At the close picture we can see part of a Scythian comb made of gold and decorated with a battle scene. The detail is excellent and it is probably made by Greeks of the same area. Such detail remains unusual even today and we also have to consider that the gold melts at 1100°C. I thing we own a little more respect to the ancient technicians and artists.

Gold seems to be the favourite metal of all kings. Since the beginning of history at the grave or tomb of every important person has been usually put a lot of gold objects.

Where mythology meets history we have the myth of 'golden fleece'. If we overlook the literary details the fact that remains is that we have a description of a traditional art of collecting cold to this specific area. On the riverbed of some rivers that had gold inside them, there were been placing sheepskins. After a while some gold had stuck on the hairs but the sand was not! So these sheepskins were becoming golden. Then they had to put out of the water and wet under the sun. After that with a good brushing the collected gold was separated.

As you understand the Argonautic campaign maybe was a campaign for gold! This explains some details of the myth better...!

Incas had available a gold of different quality. The specific gravity of the usually used gold is 19.3 but the gold used by Incas had only from 8 to 9. Of course it is lighter. The why and how remains unexplainable.

plating

At Peru, at the champaign Tsan Tsan, found coins of a civilization before Incas, the Tsimous. These coins are made from copper but over the copper there is applied silver or gold. Something like that has been also found at the Colombia from Tsimbtsas. Today we can do something like this only with electrolytic methods. How did they manage such achievement? Can it be with steam of these metals?

At the Egypt has been found some objects with a very slim gold plating on them such as we can achieve only with modern electrolytic methods.

Do you know anything related?

weird metals

Close to Dorchester of Massachusetts (USA) has been found a metal vase decorated with layers of silver. Its strength is excellent because it handled easily the explosion of dynamite but we don't know what kind of metal is it.

Another almost unknown metal is the Asokas' column that is made from iron that does not rust (not steel) and the gold from Incas that has the half of the gravity weight of the ordinary gold. These maybe are products of an unknown process...

In a marble plate found at Elefsis (near Athens) there is an order for some metal parts of specific quality and specific shape and cylindrical poles. Also there is a specification in the text for lathe to be used for metals and not for wood or hardened clay.

In a marble plate found at Elefsis (near Athens) there is an order for some metal parts of specific quality and specific shape and cylindrical poles. Also there is a specification in the text for lathe to be used for metals and not for wood or hardened clay.  At the Greek island Ikaria at the coast of Kionion at the place Siderocapso has been found a very big kiln for metals. Its diameter is 3.6 meters and its height over 3.4 m. It is build with schist and pegmatite. Internal there is ceramic material that is turned to glass because of the high temperature that went at least up to 800°C.

At the Greek island Ikaria at the coast of Kionion at the place Siderocapso has been found a very big kiln for metals. Its diameter is 3.6 meters and its height over 3.4 m. It is build with schist and pegmatite. Internal there is ceramic material that is turned to glass because of the high temperature that went at least up to 800°C. At the close picture we can see part of a Scythian comb made of gold and decorated with a battle scene. The detail is excellent and it is probably made by Greeks of the same area. Such detail remains unusual even today and we also have to consider that the gold melts at 1100°C. I thing we own a little more respect to the ancient technicians and artists.

At the close picture we can see part of a Scythian comb made of gold and decorated with a battle scene. The detail is excellent and it is probably made by Greeks of the same area. Such detail remains unusual even today and we also have to consider that the gold melts at 1100°C. I thing we own a little more respect to the ancient technicians and artists.