|

|

|

|

|

|

|

|

"Alloying of Carbon Steel to Improve its Corrosion Resistance in Atmosphere"

Carbon steel produced by local industries has one main disadvantage that it develops brown discoloration on the surface due to corrosion upon atmospheric exposure in stock yards. Surface discoloration of steel products affect the sales, naturally. One way of getting rid of the discoloration problem is to modify composition of the local carbon steel with minute additions of appropriate alloying elements such that the price of the steel will not be affected.

The research has shown that alloying elements such as P, Cu, Ni, and Cr increase corrosion resistance of weathering steels. In the proposed research, the locally produced steel will constitute the basis of the study. Objective is to improve corrosion resistance of the steel to atmospheric exposure in this environment. For this purpose, the steel will be alloyed with varying amounts of P, Cu, Ni and Cr and tested for corrosion resistance using electrochemical corrosion measurement techniques in the laboratory. The research will be continued until most cost effective alloy steel with acceptable corrosion resistance can be obtained.

"Evaluation of Coating Systems to Prevent Corrosion of Poles in Distribution Overhead Network"

Service life of steel and wood poles in different areas in Saudi Arabia is shortened due to severe corrosivity of the environment caused by abundance corrosive species in soil, groundwater and atmosphere. This leads to collapse of the poles prematurely much earlier than their design life. This is a serious problem faced by electricity companies in Saudi Arabia.

Therefore, the objective of this proposed research is to identify best performing coating system that protects poles against corrosive action of environment in Saudi Arabia.

Following a thorough literature review, several coating systems will be selected for testing in laboratory and field. The selected coating systems will be subjected to accelerated testing in the laboratory using salt spray chamber (SSC) in accordance with ASTM standard procedures. The performance of each coating system will be evaluated utilizing electrochemical corrosion monitoring methods. Three or four of the best performing coating systems in the accelerated tests will be exposed to severely corrosive environmental conditions at Jubail Industrial City (JIC), which combines both marine and industrial atmospheres. Coated panel specimens will be exposed to underground and above ground environments. They will be subjected to thorough inspection, test and analysis to determine their performance under field conditions. The investigations will be done according to ASTM standards, and will also involve the use of techniques such as SEM, EDS, XRD, FTIR, and/or AC impedance.

"Inhibition of Reinforcing Steel Corrosion under Atmospheric Condition"

Atmospheric corrosion is an electrochemical process which primarily results from conjoint action of oxygen and moisture. Atmospheric parameters that affect corrosion are humidity, pollutants and temperature. Generally the atmospheric corrosion rate of metals increase rapidly when the relative humidity rises above a certain threshold value known as the "critical relative humidity", below which corrosion is negligible. The most prominent corrosive pollutants which prevail in marine-industrial atmosphere are sulfur dioxide and sea-salt. Two together exert a synergistic corrosive effect which aggravates corrosion of metals to the extend several times beyond the corrosion that would be caused by each of these pollutants alone.

The atmospheric conditions in the Arabian Gulf region is corrosive to metallic structures due to high relative humidity, high ambient temperature, especially during summer, and high levels of contamination of the atmosphere with sea-salt and sulfur dioxide originating from the Gulf and industrial complexes in the region.

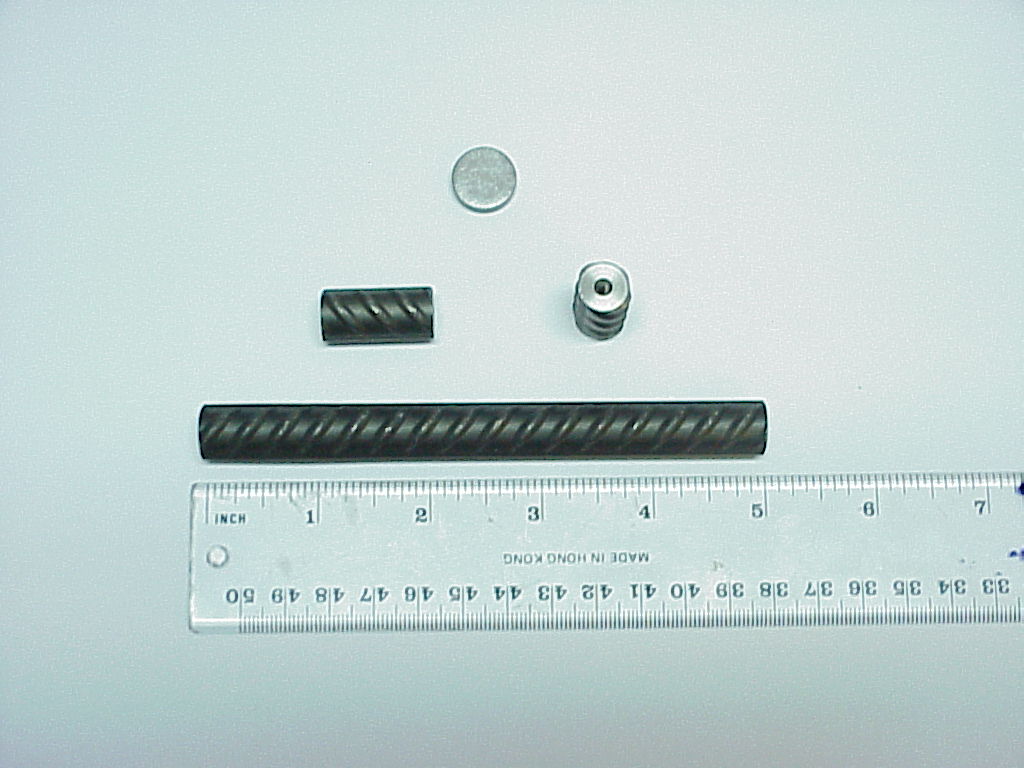

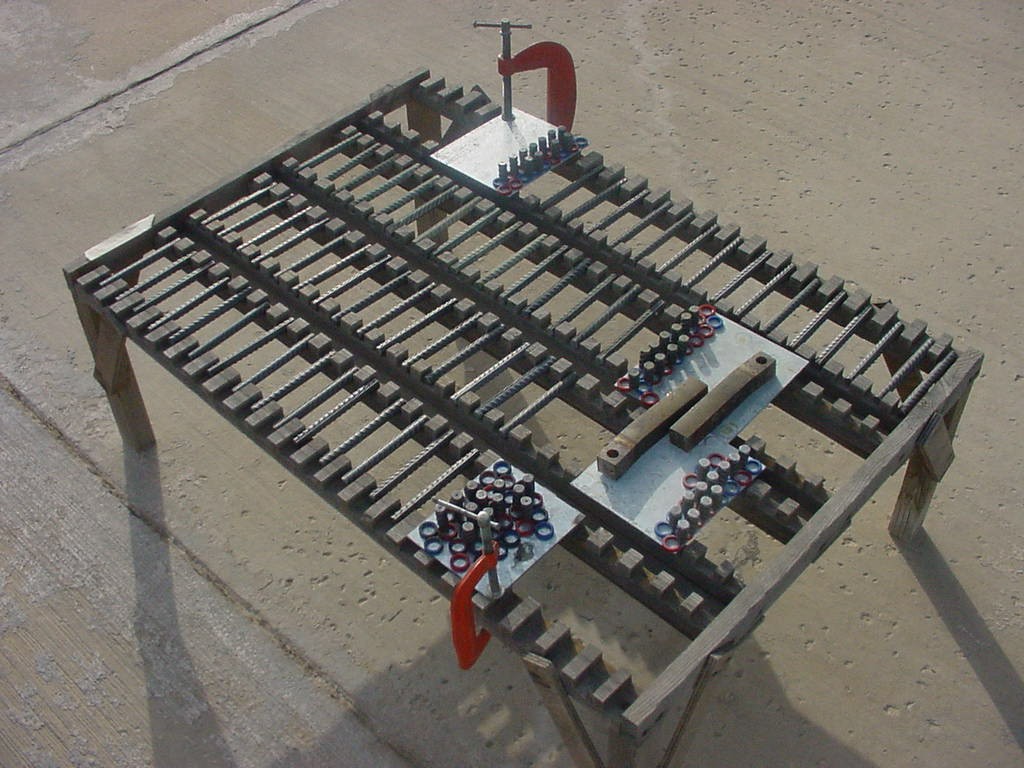

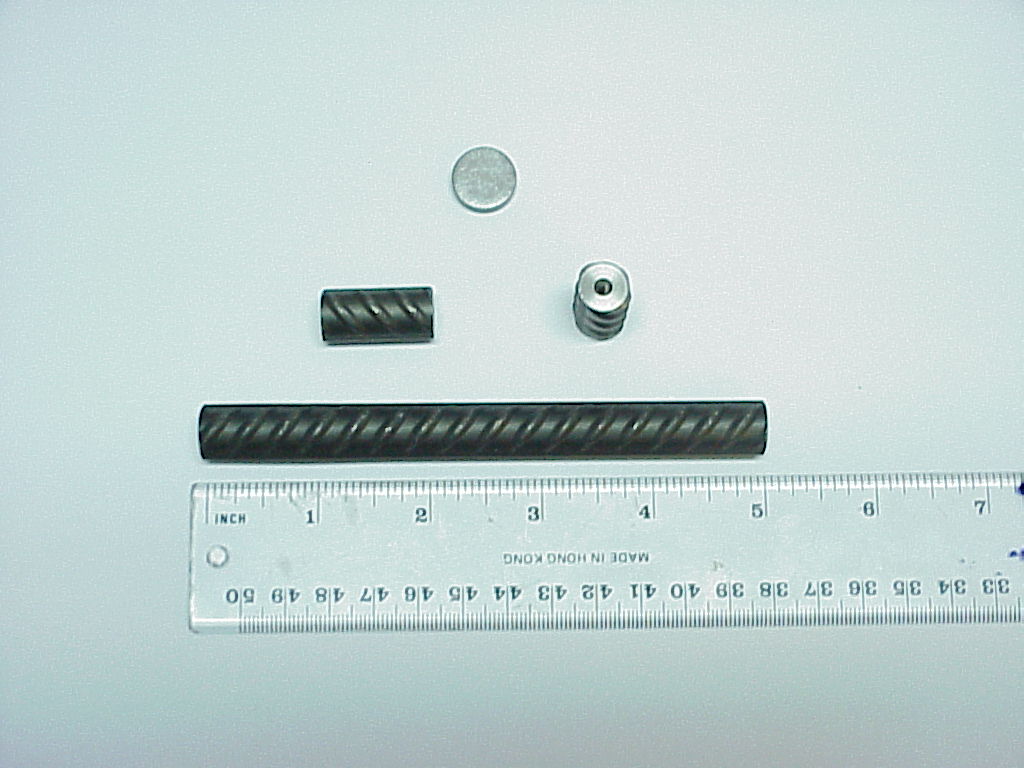

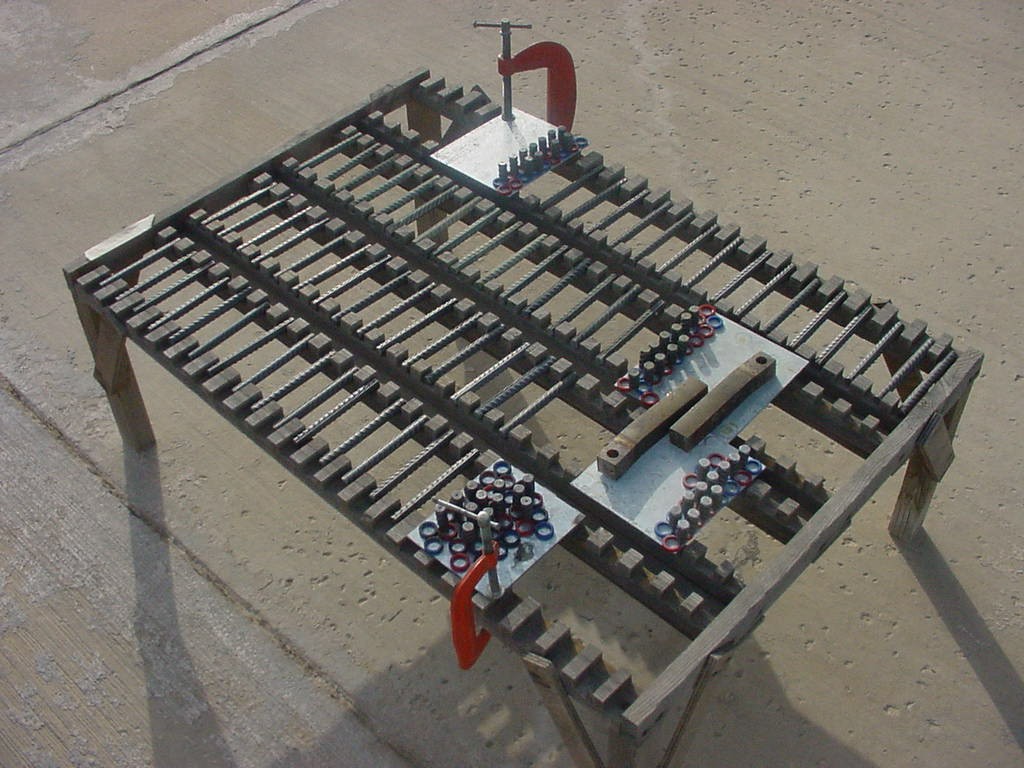

The Saudi Iron and Steel Company (HADEED), in Jubail, produces about 2 million metric tons of formed and smooth, hot and cold rolled steel rods of various diameters. The mechanical properties of HADEED steel products meet international standards. However, one serious problem they face is the discoloration of their steel products in the stockyard in Jubail due to atmospheric corrosion.

During the last several years, there has been significant progress in the research results obtained with non-proprietary inhibitors to prevent corrosion of carbon steel in outdoor exposure in the Gulf environment. The objective was to search for an inexpensive inhibitor to be used in the steel production line to prevent atmospheric corrosion/discoloration of the steel surface in the Arabian Gulf region.

For further improvement of the inhibitor effectiveness to prevent atmospheric corrosion of carbon steels, research will be continued with mixed inhibitors. It is envisioned that mixing of two or more chemical compounds with inhibitive properties at various proportions will result in a mixed inhibitor having enhanced overall inhibitive characteristics. The research will involve selection of more than one inhibitor compounds based on the already completed research results. The selected inhibitors will then be mixed at appropriate proportions and tested in the laboratory for their effectiveness in retarding atmospheric corrosion. For evaluation and testing, electrochemical corrosion monitoring methods will be utilized.