|

|

|

|

|

|

|

|

"Influence of Rubber Toughening of an

Adhesive on the Performance and Degradation of Adhesively Bonded Metal Joints in

Aggressive Environment"

Adhesives are fast becoming the fastening of choice because adhesion is faster, neater, lighter, and cheaper than bolts, rivets, and the like. Adhesives result in more uniform distribution of stress and increased fatigue life. They also help prevent or reduce corrosion between dissimilar metals, or galvanized and ungalvanized steel. The most common of the high-performance structural adhesives are epoxies, especially in automotive and aircraft industry. Epoxies are attractive because they cure without producing volatile by-products, their shrinkage upon curing is low, and they are able to bond well to a variety of treated or untreated metal surfaces.

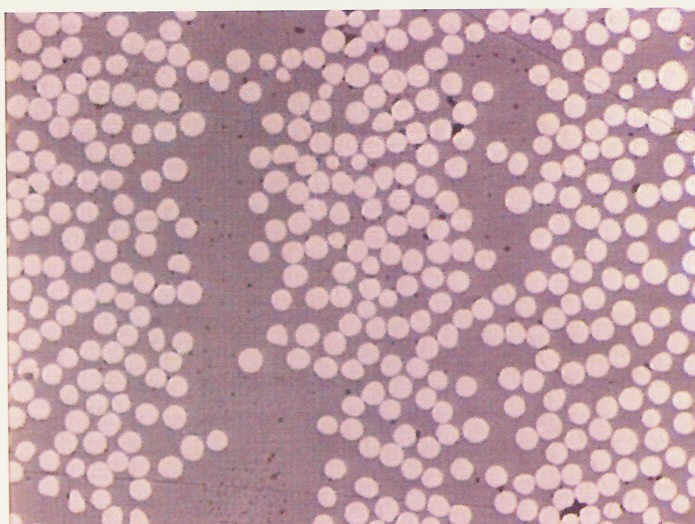

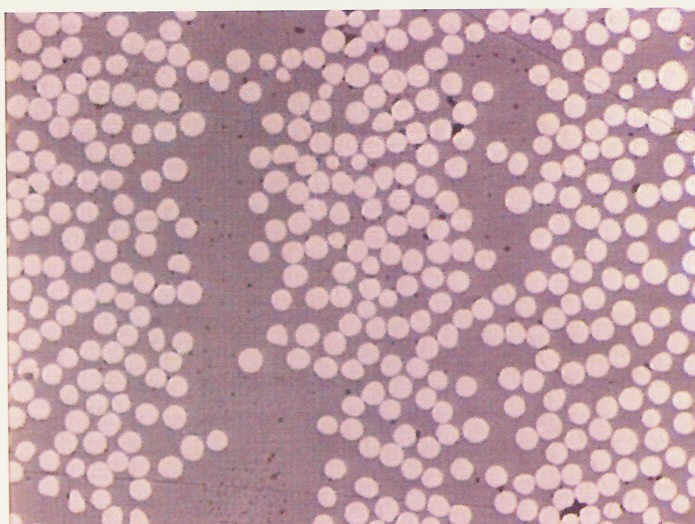

However, unmodified adhesives, such as epoxy resins, are brittle and liable to cracking. Their toughness/crack resistance can be improved considerably by including a toughening agent, such as liquid rubber, prior to curing. In the curing stage micro-phase separation occurs with small rubber-rich domains dispersed within the epoxy matrix. The rubber particles essentially act as shock absorbers, absorbing the fracture energy. An experimental program is described to develop information on the influence of rubber particles within an epoxy adhesive on the performance and degradation of adhesive joints in non-corrosive as well as corrosive local (Saudi Arabian) environments.

"Evaluation

of Durability and Conductivity Characteristics of Epoxy Adhesives

Containing Metal Powder"

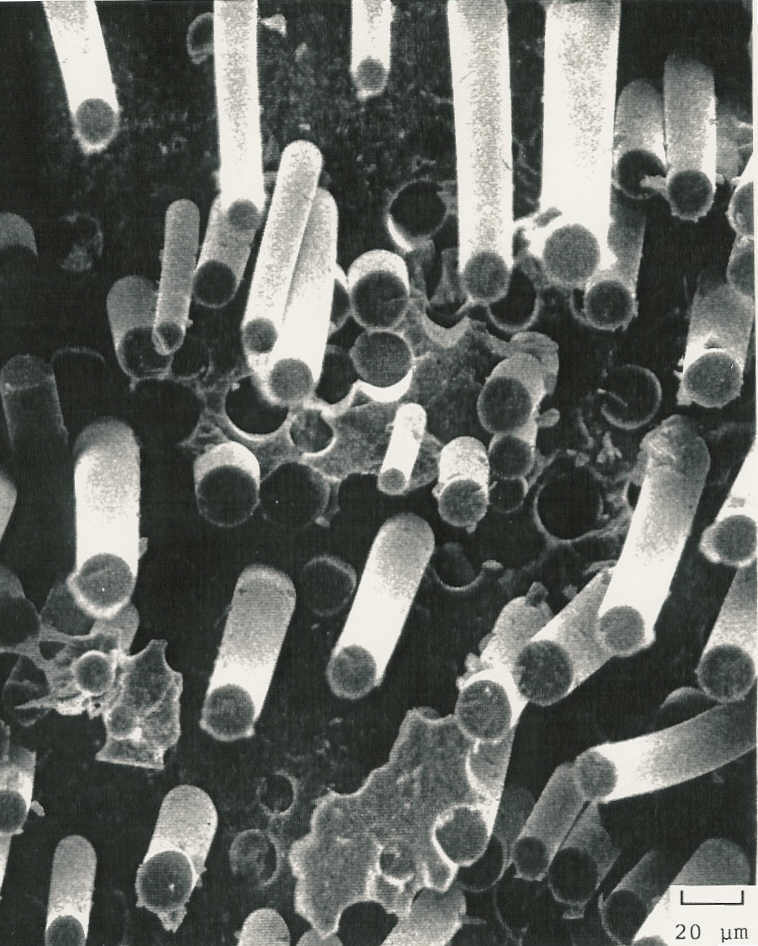

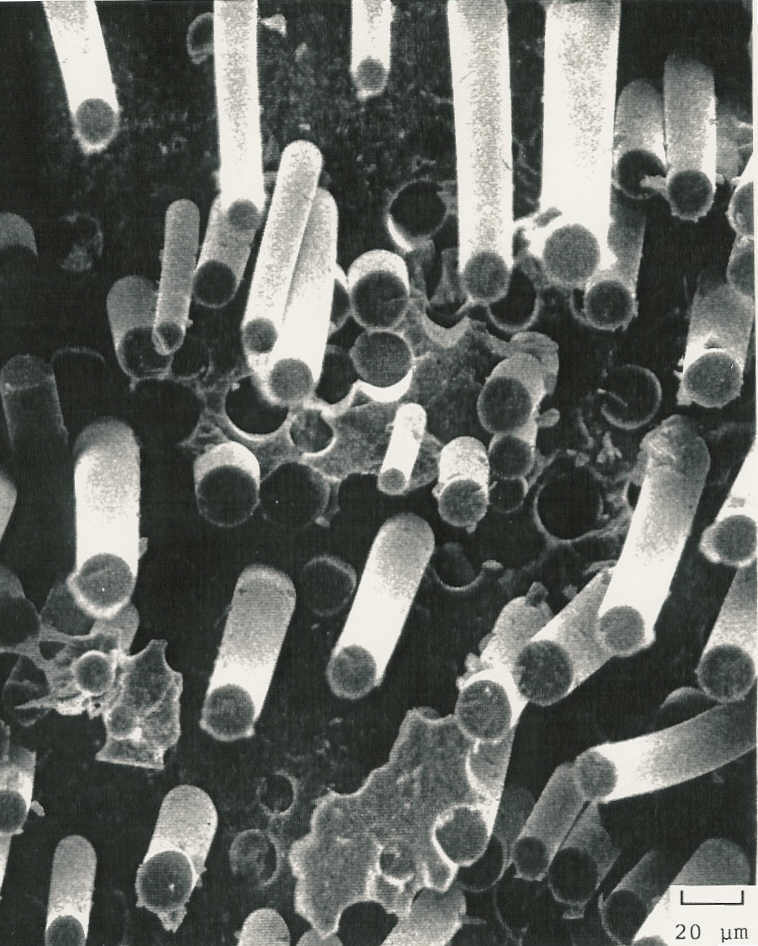

Adhesives are fast becoming the fastening of choice because adhesion is faster, neater, lighter, and cheaper than bolts, rivets, and the like. Adhesives result in more uniform distribution of stress and increased fatigue life. They also help prevent or reduce corrosion between dissimilar metals, or galvanized and ungalvanized steel. The most common of the high-performance structural adhesives are epoxies, especially in automotive and aircraft industry. Epoxies are attractive because they cure without producing volatile by-products, their shrinkage upon curing is low, and they are able to bond well to a variety of treated or untreated metal surfaces. They are usually formulated with metal fillers to increase their thermal conductivity. However, there are still many unknowns of material properties for comprehensive utilization of epoxy adhesives with metallic fillers.

The objective of this research is to determine durability, electrical and corrosion properties of the material under polluted environmental conditions.

1. Adhesive specimens will be subjected to unidirectional exposure to environment containing Cl-1 and SO-4 ions. Unidirectional penetration of water, Cl-1 and SO-4 with time and their diffusion into the adhesive specimens will be measured. Effect of filler quantity on water, Cl-1 and SO-4 penetration will be determined.

2. Conductivity (or resistivity) of the adhesive will be determined as a function of filler quantity.

3. Degradation in durability properties in Cl-1 and SO-4 containing solution with time will be determined.

|

|

|

|

|

|