Building Custom Rifles

Michael Davis and Parish Davis

This is a big file--please be patient!

The building of a custom rifle is begun by selecting a suitable action and then prepping the same so that the barrel will fit to it with precision. This Remington Model 700 short action will be built by Gunsmith, Parish Davis as a benchrest gun for himself. All the remainder will also apply to a Mauser action with the exception that a Mauser has an inner and outer breeching shoulders that must be fitted, simutaneously. The face of the action is trued and squared with it's central axis by holding it in the lathe in a fixture. About 10 thousands was removed in order to square the action face. The locking lugs are lapped.

Facing the action with a centering spindle/fixture.

Lapping the locking lugs--this homemade "thingy" holds pressure against the bolt face as you turn the bolt with lapping compound. The lugs are worked until they make full contact as checked with dye.

The bolt was fluted. A tactical bolt handle was made and welded on.

The shroud was given a similar treatment of fluting.

It was decided that the scope mounting holes would be redrilled to accept 8/40 screws. This was done to make the scope mounting system more secure and stronger.

The front action screw was recut for a Hex head "National Fine" 3/8-24. This is a stronger bolt for the critical action torquing area.

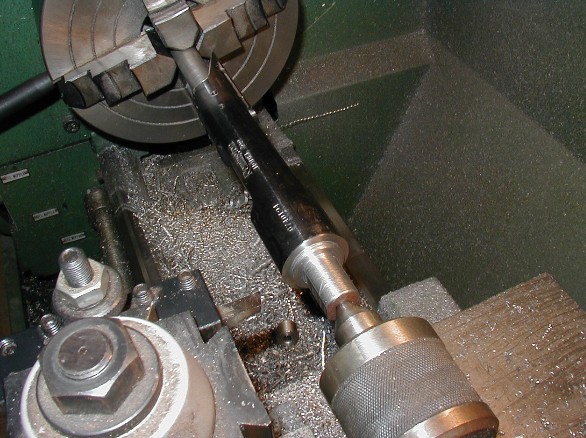

Parish selected a Shilen Match Blank in .308--This is a "humongous" unturned barrel blank. He centered it in the lathe and began to cut the required threads from the breech end and chambered it to minimum dimensions.

The finished thread for a Remington 700. The barrel is set up so that there is very little play in the closed bolt and with minimum headspace. The bolt will barely close on a "go" guage. A sporter chamber would not be set as close. Also notice the flat section where the over-sized recoil lug will fit. The lug is precision ground so that it is flat and maintains the "square" dimensions between the barrel and receiver when the barrel is torqued. The lug was made by Tubb.

Parish screws the action "on" and checks the chamber with a "go" guage. He continues to trim the barrel breeching shoulder until he arrives at his desired headspace dimensions.

Parish breaks the edge of the threads with a file as it spins in the lathe. He holds emery cloth against the barrel edges to polish and smooth them. Always wear eye protection and observe safety rules around turning machinery.

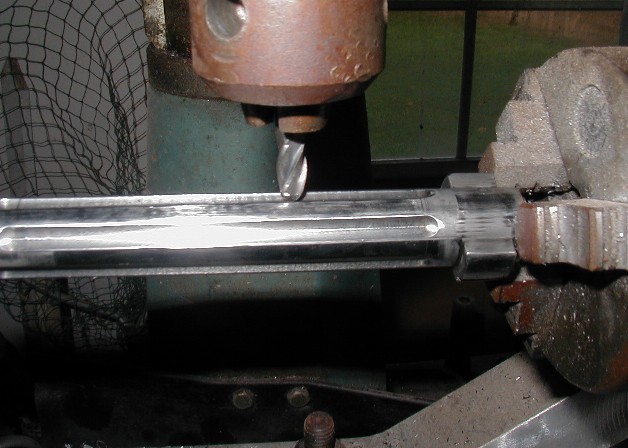

The barrel was fluted. It is just cosmetic on this barrel because it is so large--the weight reduction is negligible.

The barrel was cut 21 Inches O.A.L. and was crowned in a recessed benchrest style.

Here is the action and barrel fitted with an oversized recoil lug. The bolt handle was cut off and a tactical knob, turned from bar stock, was welded into place.

For a stock, Parish cut some zebrwood into planks and glued together. He then cut it to a pattern which he made from a Remington 40X benchrest stock which he changed slightly and added a cheekpiece to. Here is the finished product

And a closeup--note the stainless washer made for that big action screw.

And another close-up.

THANKS FOR LOOKING!

All text and photos copyright 2003 Michael Davis and Parish Davis

Parish Davis D/B/A/

Great Southern Gunworks