made : 15-06-1997

last modified: 12-04-2006

Imp Transaxles

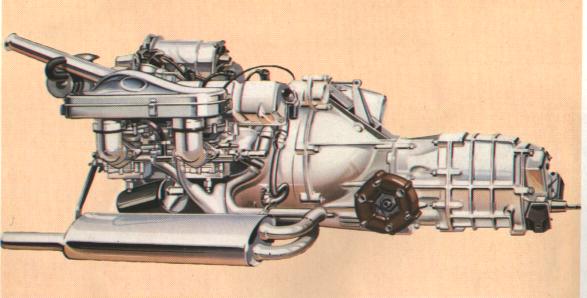

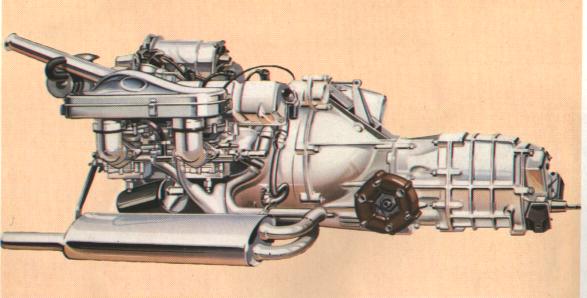

A sport engine and transaxle.

The Hillman Imp Transaxle is one of the nicest in it's class and of it's

time, even compared with the gearboxes today it's gearshift is short

light and precise.

Why?

- It contains the gearbox and final drive in one package.

- It is small and light, because of it's aluminium housing.

- It has synchro's on all it's four gears (advanced for 1963 !).

The Imp's transaxle is one of the most reliable parts on the car, but after

a long time and hard use and no service (read no new oil) it can develop some faults.

Common problems are:

- Floppy gearshift.

- Oil leaks.

- Difficult gear selection.

- Whining sounds.

- Reverse gear not working.

- Jumping out of gear.

- Play on the final drive.

- Getting stuck into gear(s).

- Broken off gearbox mountings (accident damage).

- Reverse gear to easily engaged.

Transaxle drawings from the Rootes Group Service manual:

Floppy gearshift:

See picture of gearlinkage

The most common fault is a floppy gear change, mainly caused by a worn or

disintegrated cup (156).

A replacement cup of improved material can easily be fitted by drilling out

four rivets (which attach 161 to 165) and using phillips screws.

Don't forget to file off any sharp edges and grease the cup prior to asembly.

Oil leakage: not enough oil/old oil

See picture of parts and names.

A classic english car habit.

Early transaxle didn't have an air vent, (later types did have one on the

reverse gear housing)

It causes excessive oil pressure when the gearbox is in use and as a result the seals

can't cope with the pressure when they start to wear.

Later type transaxles have an air vent on the front end (gear selector end).

One can check if it's blocked by inserting a small wire.

Otherwise the seals have to be replaced on the output shafts(115, plate C section F)

Placing an extra O-ring on the shaft might solve the leak, "quick and not so dirty"

Also the clutch shaft oil seal(32) will sometimes need to be replaced.

And don't forget to renew the little O-ring on the gear selector input shaft.

Once I rebuilt an Imp, renewed the clutch main and slave cilinder and clutch unit

and still it didn't want to select gears properly, changing the oil finally did the trick.

Old oil can also ruin a perfectly good box as well as not enough oil.

2,5 liters of EP80 is all you need, not expensive at all and if bought in the right bottles

one can squeeze it right in after jacking up the car, make sure you release the jack to

make sure you don't overfill the box, have a pan at handy ;-)

Difficult gear selection:

See picture of parts and names.

The first gear in particular is prone to this mostly caused by abuse of the owner.

It's caused by worn baulk ring (62, 1st gear) and this needs to be replaced.

(The baulk ring should move easily over the gear wheels when oiled).

Sometimes it can be so bad that selecting first gear makes a noise.

selection is only possible while car is not moving.

A good trick I once did was exchanging the first gear baulk ring for the one

of forth gear, which works fine for both gears.

(Rootes has used many types of baulking rings so make sure you buy the right ones)

Also check the teeth of the hub, especially on the side of the difficult selectable gear

Check nr 65 and 73 the speed synchro hubs especially for broken out pieces from the top sides

If you look on the backside of the baulk ring and you see wear patterns then the baulk ring has

even worn so far that it's sholder is touching the gearwheel and should be replaced

The gap between them should be about 1.0 / 1.5 mm

Another common problem is difficulties in shifting down from three into second gear at relative high speed

if you hear a "chunk" sound at speed and not if you slow down before shifting into second this

might be due to normal wear on the taper roller bearing and bushes of the output shaft

If you dismantle the reverse gear cover and inspect the end nut for tightness and it's lose

holding on the tab only then you found the problem, dismantling the whole box is not neccesairy

Just check the bearing and spacer ring underneath

If this nut is still tight then dismantle the box and inspect the 2nd gear baulk ring for wear

Whining sounds:

See picture of parts and names.

Whining sounds are regularly due to a low oil level in the box.

The first bearing which suffers from this is the top ball bearing(43).

It is a common bearing and has to be replaced.

If the oil level gets even lower temperature might get so hot that in one case

the output shaft taper roller bearing (55) welded itself to the shaft making it very

difficult to remove the gearbox casing, You'll need a chisel and grinder to destroy

the bearing.

Reverse not working:

See picture of parts and names.

This fault is mostly caused by a broken reverse gear pivot post(51).

Replacing is easy but the transaxle has to be removed from the car, so the

engine has to come out.

Only the reverse gear casing has to be removed from the transaxle.

Jumping out of gear:

See picture of parts and names.

This is a fault mostly common with early type transaxles, the ones with the

shifter balls, springs and square plates in the synchro hub assembly.

I've noticed it's 3rd gear in particular.

It's caused by a worn selector shaft 77 or 80.

They have the same serial numbers so are interchangeable.

A little trick that might help for a short while is increase the tension of the

spring of the main gear selector shaft detent ball.

Play on the final drive:

I haven't done that one before, but will do as I got a spare tranny with that

trouble.

I'll let you know when I come round to it, watch this space ....

Stuck into gear:

(See picture of Transaxle parts and names and synchrohub)

Once I have rebuilt a gearbox which was jammed into 4th gear.

So what happened and why ?

Because of wear on the grooves on the 4th gear side of the synchro hub(73),

the spring(A) in the sleve of the hub jumps over the grooves and in this

case jumped free and was stuck in between the baulking ring(75) and the

fourth speed gear wheel(76).

This caused extra pressure on the hub assembly(73), which in it's turn

damaged the 3rd gear bronze bearing(72).

The woodruff key (from the hub assembly) which is supposed to lock this

bearing(72) broke free and turned the bearing off causing axial play of

the wheels on the output shaft(58).

I've replaced the 3rd bronze bush(72)

and replaced the

second hand 3rd/4th gear synchro hub assembly(73) of a later type gearbox.

(See for picture: hubassembly, in this case a 1st/2nd gear hub assembly, which

can be seen as it only has a single grove in the splines)

Then reassembled the box and measured the size of the preload washer

(56).

I've put the gearbox back together successfully and it is still working fine

after 3500 km now !

Another problem with gears being stuck on early transaxles is that the

shifter plate(34) breaks in two and jamms the gears.

I had this once while shifting gear from 3rd to 4th causing a horrible

sound when releasing the clutch.

We had to tow the car home with the clutch applied.

Broken off gearbox mountings (accident damage).:

This happens when the car is hit heavily from behind.

(It happened to me twice).

The reverse casing needs to be replaced, this is the only part of

the housing which can be replaced.

Old type- and new type reverse transaxle casings can be exchanged.

Reverse gear to easily engaged:

Selecting from 3rd back in 2nd and you hear a horrible noise... oops

it's the reverse !

This one is caused by spring(78) of the reverse plunger being to weak.

A standard Imp engine and transaxle.

General Data:

Oil: 2.5 liter of E.P. 80 oil.

Torque wrench settings:

Drain and filler plugs 48 Nm.

Output shaft 62 Nm.

Input shaft 62 Nm.

Bevel pinion bearing pre-load:

New bearings: 1.6-2.3 Nm.

Old bearings: .8-1.1 Nm.

Casing nuts 1/4 inch UNF 15 Nm.

5/16 inch UNF 16 Nm.

Mounting cover bolts 5/16 UNC 22 Nm.

Crownwheel to cage (bolts marked X or 75) 55 Nm.

Differential shaft locknuts 180 nm.

Bellhousing nuts 35 Nm.

Clutch release lever nut 15 Nm.

Detent retaining plug 10 Nm.

.... to be continued

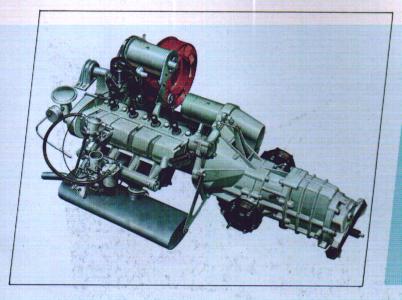

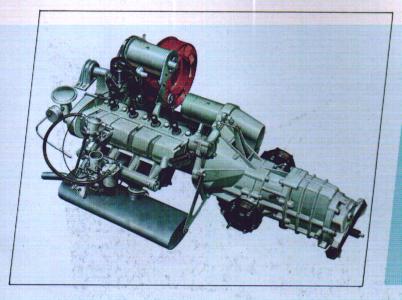

Rootes engineers playing with a demo transaxle at Linwood Scotland.

If you find any incorrect things or have any comments don't hesitate to contact me.

When you have experienced other transaxle trouble let me know !

More technical data can be found on Frankas Imp site:

imps

Rootes service bulletins

Gear Technology

Back to my Classic Cars main page

Bert's email adres