The following was written by Mike Kendall of AFV INTERIORS WEB MAGAZINE for Vol 1, No. 7, 1999. AFV INTERIORS is a Kit Hobbiest orgranization and he has very graciously given permission to the "AMTRAC PLATOON" to display it on this website, all items in this article are to be used by permission only. Webmaster

Load time is slow due to all the great detailed graphics and pictures.

US Landing Vehicle

Tracked,Personnel, Model 5,

"LVTP-5", Part 1

Picture

1:

Picture

1:

Plans for the series of vehicles called Landing Vehicle, Tracked (LVT)

date back to at least 1940, perhaps earlier. The U.S. Navy and Marine Corps

approved most of the ambitious Borg Warner Corporation LVT design in the

late 1940's and manufacturing began in the early 1950's. The LVT vehicles

entered service with the US Marines in 1955-56 and replaced a number of

Amtrac types that had been used extensively from WWII into Korea. These

new Amtracs were roomier than their predecessors and were completely enclosed

in light armor. The LVTP (P for "Personnel") was fully amphibious without

preparation, other than closing all lower ports and hatches. Early models

of the LVTP included both an unarmed cargo version as well as a personnel

transport with a MG cupola for ground support located at the front of the

roof. The typical crew load included a Driver in the bow on the port (left)

side, a Commander (Crew Chief) at the starboard bow, and a third member,

sometimes called the Assistant Driver and sometimes the Gunner depending

on the manual you read and the mission of the Amtrac. The vehicle could

hold between 25 and 34 fully equipped Marines, seated in four rows of folding

bench seats--one bench along both sides of the cargo compartment and two

back to back down the center. On the other hand, as many as 45 passengers

could be transported standing up with the middle seats removed and the

side benches folded up against the wall cabinets. The last batch of -5s

were upgraded with a few minor changes to the final version of the Amtrac,

the LVTP-5A1.

The -5A1 in this USMC photo is having its engine and transmission pulled

by a recovery vehicle version of the LVTP-5, called LVTR1A1. Since we are

looking at the rear of the left LVTP-5A1, we are also looking at the rear

of the powerpack, the white transmission. Notice the engine roof access

panel has been removed and is setting on the barrels to the right, complete

with the later style exhaust/intake modified structure bolted to the center

of the panel.

Picture

2:

Picture

2:

Amtrac crews in Vietnam operated with the seats removed most of the

time except when the LVTP-5s provided ship to shore duty over extended

distances. When operating in the cargo role, the LVTP-5 could haul 12,000lbs

through the water and 18,000lbs on land, loading and unloading through

the cable lowered ramp at the bow when on land or through large hinged

doors on the roof when at sea. The engine powering all the different variants

of the LVTP was a Continental V-12, liquid-cooled, gasoline motor, which

remained constant throughout the years with only few refinements in exhaust

and air intake ducting in a modified roof vent system in the latest versions.

By 1957 the last LVTP-5 rolled off the assembly line, to be replaced shortly

by an even more refined water taxi.

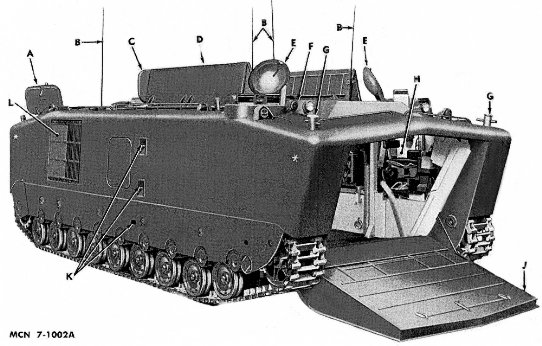

This image and others from the LVTP-5 Marine Corps Maintenance Manual

(ORD-MM-7000A, October, 1957) were provided to us by Museums Branch, History

and Museums Division, Headquarters Marine Corps. The picture illustrates

the layout of the front and right sides of an early LVTP-5. Hydraulic motors

and winch cables lower the large ramp, and with the ramp in the lowered

position you can see the driver's position up on the left sponson near

the bow. Thomas Williams, who crewed an Amtrac in Vietnam, reports they

sometimes connected a cable to the end of the ramp and the top of the opening

so when the ramp was lowered it stopped when it was level (instead of lying

down at an angle). It could then be used as a table for cleaning equipment

or sorting supplies. The hose rising at an angle (below and next to the

driver's seat) is one of the bilge discharge hoses. The driver's domed

over-head hatch is seen in the open position.

On this near side of the Amtrac sat the vehicle commander, usually a

Crew Chief, and he had the same over-head cupola and hatch as the driver.

The interior paint color of these hatches was the same as the primary exterior

color, USMC green, but most of the surface was covered with a thick, black,

leather head bump pad. The large cargo doors on the roof are shown in the

open position, the hatches hinged on their outside edges and folding in

the middle to fully expose the interior of the compartment below. The inside

color of these long hatches was also generally the exterior color, USMC

green. Down inside, the long passenger seats were padded and covered with

flat black leatherette on the surfaces and all had USMC green painted support

legs. Also visible here is one of the rear engine access hatches, opened,

as well as the radiator air exhaust port on the side of the hull.

This is the first of a two part series on the LVTP-5. This part will

cover the general development of the vehicle and the commander's station

on the right side while Part 2 will explore the driver's area and the engine/transmission

compartment at the rear.

Picture

3:

Picture

3:

From the same maintenance manual we have this top and rear view of

the basic LVTP-5. The engine is located in its own compartment at the rear

of the hull and a large engine access panel on the roof can be unbolted

to allow access to the engine and removal of its major components. From

inside the vehicle there is also access to the engine through a large panel

on the back fire wall of the cargo compartment. On top of the roof engine

access panel you can see the early exhaust grating and deflector that will

be changed later with the LVTP-5A1 version of the Amtrac. To either side

of this panel are two engine access hatches used by the crew for engine

access for minor maintenance. There are two domed air blower covers on

the roof, the one closest to us at the left is for the scavenger blower

in the engine compartment and a similar blower is located on the forward

left corner of the hull, behind the driver's hatch. These blowers exhausted

stale air from inside the LVTP and fresh air then entered from open hatches

or three smaller ports also located on the roof. Even with this system,

the air inside a closed up and operational LVTP-5 was normally pretty thick.

Forward of the two engine access hatches are two radiator intake grills

covering the location of the twin engine radiators and fans below. While

on land, the engine driven fans drew cooling air into the ducts and through

the radiators inside, then exhausted the air through the hull side grates.

When in the water, the driver turned off the fans and the sealed radiator

compartments were allowed to partially flood to cool the radiators. That

is why you often see water pouring from the side grates when Amtracs come

ashore. Forward of these grills are two entrance hatches into the cargo

compartment with radio antenna bases outboard and two of the inboard fresh

air ports I mentioned earlier. Taking up most of the roof (forward of the

two hatches) are the large opened cargo hatches, in this case showing how

they are articulated in the middle to fold back on themselves. Ladders

were stowed to the outside surface of the cargo hatches and were used at

the back edge when the hatches were open to get from the cargo compartment

floor to the roof and then outside. The driver's cupola and surrounding

vision blocks are at the front left of the roof and the commander's are

to the right. In this case, the MG turret is not mounted and a round cover

plate is bolted on the roof in its place.

Picture

4:

Picture

4:

This is the commander's closed over-head cupola and hatch with its

four surrounding M17 periscopes that allowed clear views forward and to

the side. Another periscope, an M17C, is aimed across the raised roof section

for a diagonal view of the opposite front corner of the Amtrac. The hatch

is opened with the assistance of a set of torsion springs inside the hollow

hinge bar you see here. A spring-loaded hook holds the cover latched in

the open position and the hook can be released from inside the hull by

pulling down on a hook shaped eye located at the base of the cupola. A

locking handle on the under side of the hatch locks it closed and provides

a grip for opening and closing the hatch. A watertight seal keeps sprayed

water out and there are rubber seals around all the periscopes for the

same reason. Just outside the cupola you can see a number of items on the

roof including another of the fresh air intake ports next to the antenna

base (at the lower right of the picture). Also seen here is one of the

large lifting eyes--another is located next to the driver's cupola on the

right and two more on the aft roof. Forward of the hatch you can see the

armored cover for the blackout bow marker light and the unprotected light

next to it is a detachable driving light. At the far right end of the hatch

hinge you can see the hold open hook that we mentioned earlier welded on

the domed cover.

Picture

5:

Picture

5:

If we open the commander's hatch and lower ourselves down, we will

stand first on his seat, and then step down from the sponson onto the floor.

The commander's seat and surrounding gear would look like this image from

the Manual. We are looking across at the seat, which is mounted on a support

post that is bolted on top of the sponson and also onto the hull wall.

The seat is composed of a metal formed bottom seat pan (normally black,

but shown here white) that slides up and down the support post in a similar

way to driver's seats mounted in many US tanks. This allows the occupant

to ride either under armor or with his head out of the hatch. The spring

for raising the seat when the height adjustment lever is pulled and your

weight is lifted off is hidden inside the post. The seat adjustment levers

can just be seen behind and above the padded lever control box next to

the seat. The control handles stick up above the padding and includes the

forward lever for vertical seat adjustments, and the rear handle for horizontal

adjustment (B). The wide OD green seat belt is shown rolled up on either

side of the seat bottom. The height of the seat back is adjustable via

a wing nut (C) and the back can be reclined by the control lever at the

base (D). Directly behind the seat is the one portable CO2 fire extinguisher

carried in the vehicle although there are three others fixed in the engine

compartment for fires back there. The commander's green radio control box

is mounted at his right shoulder and is where he plugs in his headset and

microphone for communication in and out side the vehicle. The padding on

the seats is typically covered by flat black or gray colored plastic imitation

leather, but USMC green canvas covered seats are also seen and are probably

a repair of the original.

Picture

6:

Picture

6:

A clamp on the bulkhead directly behind the commander could hold a

small AN/PRC radio, shown in its up and stowed position in this handbook

illustration. The radio could be either an 8, 9, or 10 unit, depending

on the mission of the Amtrac, and it is connected to the forward starboard

antenna by the black cable you see to the upper right. The set is powered

by an internal battery and may be operated inside the vehicle, from a semi-permanent

ground installation outside, or while being carried by the operator. The

AN/PRC is matched with a handset H-33/PT that plugs into the AUDIO jack

on the panel. Because there is a high noise level in the vehicle, a headset

microphone H-63/U and chest set group are proved for the commander as you

see here; the driver has a similar radio set up. The commander's seat back

is directly below and his over-head cupola is above. The vision blocks

were easily replaced by unlatching the side handles on the mounts and then

lowering the glass block into the vehicle. A replacement could then be

inserted and the holders latched secure again. At the upper right corner

of the picture is the control handle for the fresh air intake port at this

position. Armor on the LVTP-5 was thin and ranged from 1/4 to 5/8in thick.

It was butt-welded and reinforced with structural members inside providing

a very robust, if uninspired, hull configuration.

Picture

7:

Picture

7:

Here is the commander's position and opened ramp from inside a preserved

LVTP-5A in an outside display. This and other photos in this series of

articles were taken by Kelly Jo Williams and loaned to INTERIORS by Thomas

Williams. Although a bulkhead hides most of the commander's seat in this picture, you can still see the front edge of the contoured base pan with the seat in the elevated position. Attached to the wall to the right of the seat is a storage

box for viewing blocks and forward of the position is a bracket for a first

aid kit and box type flashlight. To the left is the cable and pulley for

raising the ramp along the edge of the opening and just to the right is

what's left of a bracket on the front wall for four cans of .30cal ammo.

Notice the anti-slip covering on the floor plates and the dark color of

the floor here as well as on top of the sponson.

Most of the electrical cables on the ceiling forward of the commander's

hatch are attached to the infrared blackout lights and headlights we saw

earlier on the exterior of the vehicle. Behind the seat is a wall full

of storage boxes and cabinets for tools and other gear; the wall cabinets

extend clear back to the right side exit hatch. The interior walls and

ceiling of the vehicle are painted white, originally gloss finish but fading

with wear and time to dull white. The floor was usually painted flat black

or USMC forest green, but you will find it repainted white in photos taken

during Vietnam. Most of the webbing belts inside, such as the seat belts,

are OD green.

Picture

8:

Picture

8:

Another image from the same vehicle, although a bit darker than the

previous, shows the same position but from the opened ramp. The seat is

clearly seen here, although the back is missing. Notice the bracket holder

for the AN/PRC radio on the bulkhead behind the seat. The bracket hooks

on the hull wall forward of the seat controls were to hold the vehicle

log book and was also handy for hanging the commander's headset and microphone.

A bracket for a first aid kit and another for a box shaped flashlight are

further forward and can't be seen here. The diagonal white support on the

left is the right ramp opening support brace, and the cable running up

its top side is the ramp control cable. The hose running up the sponson

next to the seat and ending at the roof is the right bow bilge pipe, leading

up from the pumps under the floor to a discharge exit on the hull roof.

Picture

9:

Picture

9:

A small one-man MG turret was often mounted in the roof between the

commander and driver's hatches in those vehicles designated as personnel

carriers. The turret mounted the familiar .30cal 1919A1 Browning machine

gun in a cradle that was manually elevated and depressed on two trunion

pins with an elevation handle. Elevation was from +60 to -15 degrees and

on top of the domed turret is the gunner's periscopic sight assembly. The

gunner could use any of five vision blocks around the turret cupola, combining

to provide a complete 360 degree view around the vehicle roof. There were

two additional vision blocks on the front surface of the elevated turret

base attached to the roof and one of these blocks can also be seen in this

illustration. Inside the vehicle, there were locations for reportedly stowing

2,000 rounds of .30cal ammo stored in cans (250/can), but in action in

Vietnam additional ammo was stowed inside, stashed anyplace an ammo can

would fit. Below the turret could be set a short platform for the gunner

to stand on in order to better use the vision blocks and reach the gun

equipment. It was not necessary for gunners over 6ft tall.

Picture

10:

Picture

10:

This image of the inside of the turret illustrates many of the control

details. The MG gun mount at the right is complete with a green canvas

spent shell bag hanging down from the exit chute of the receiver. The MG

firing trigger is visible here (G) as well as the elevation handle (L),

although the gun could be elevated by use of the MG handle alone. To the

far left is the hand crank for rotating the turret, which is attached to

a geared drive mechanism surrounding the turret. The .30cal ammo box support,

which would hold a typical 250 round .30cal ammo can, is directly in front

of us and a green painted cylindrical battery box (M33 Instrument Light)

for the light bulb inside the periscopic sight is attached to the box support.

The M111B periscopic sight has a large rubber eye/face pad and the sight

tube is articulated in elevation to follow the gun. Above, on the ceiling

of the turret dome and off set to the rear, is a small circular head pad

glued to the armor where the gunner's head would most likely bump when

he used the gun. Only a part of the pad is seen at the top of the image.

Notice the two viewing blocks in the turret support structure, seen here

at the bottom of the image.

Picture

11:

Picture

11:

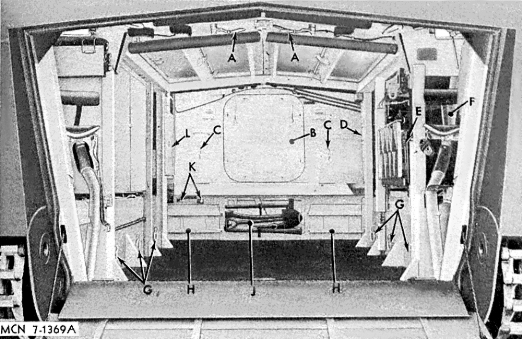

The LVTP designers located the ramp at the bow in order to make amphibious

assaults more practical than earlier Amtracs. The bow ramp placement also

allowed for a more balanced load/engine ratio when landing, since the power

pack was at the rear. Looking directly back into the hull you can get a

feel for the expansive area available for carrying cargo or troops when

the seats were removed. The lower deck flooring was steel, covered with

non-slip skid plate, and was 15ft long from the base of the ramp to the

engine bulkhead and over 7ft wide. Five companies built LVTPs, including

Ingersoll, St. Louis Car Company, Food Machinery Company (FMC), Baldwin-Lima-Hamilton,

and Pacific Car and Foundry. Around 1,000 were completed and handed over

to the Marines.

Under the floor is the bilge space and a number of individual fuel containers

to store the total of 456gal of 80 octane gasoline for the thirsty Continental

engine. The vehicle's travel range was around 250 miles on land and 65

in calm water. At the back of the compartment you can see the central engine

access hatch flanked by cargo pad tie down eyes. Down on the bottom of

the back firewall are access panels for the four vehicle batteries (H),

two secured in each cabinet. Between the battery compartments is a typical

USMC bracket box containing a set of pioneer tools. Over-head you can see

the closed cargo hatches and the handles for releasing the hatches are

visible at this end of the opening (A). At the right side of the photo

is the driver's area and directly behind him are open racks to stow equipment,

including a number of possible radio sets. The long bench seats along the

sides and center of the compartment have been removed completely from this

LVTP-5. Normally, the side benches would be folded up along the walls where

you see the vertical roof supports. When folded, the unique zigzag pattern

of the bottom seat cushion supports would be visible on both sides of the

space. The roof support beams add strength to the structure and there are

additional beams welded around the vehicle hatches and especially the cargo

doors on the roof. As I mentioned in Part 1, the primary interior color

in the LVTP is generally gloss white, with a flat black or USMC forest

green floor. But, repainted white floors are as common in period photos

as the darker original factory paint.

Continue on the Page Two