Notes from the Underground...mine.

"Blood and bone are the price of coal..."-Ewan MacColl

In one sense coal mining is simple, you dig a hole in the coal and sell what you take out.

Realistically, digging an eight foot by eight foot by x foot hole under a pile of dirt, gravel and rock sixty to ninety feet deep becomes complicated quickly, especially if you want to keep breathing. The top wants to drop on you, the sidewalls react to the removal of their support by trying to move into the shaft, the floor wants to equalize pressure by humping up, everything wants to go somewhere. Add to this the constant dripping or flowing of water from the top, the creaks and groans from the settling props and the unbelievable, total black dark of an underground mine and you have the atmosphere of terror for the uninitiated. And there is real danger, clear and present every moment you are there, everything can burn.

In one sense coal mining is simple, you dig a hole in the coal and sell what you take out.

Realistically, digging an eight foot by eight foot by x foot hole under a pile of dirt, gravel and rock sixty to ninety feet deep becomes complicated quickly, especially if you want to keep breathing. The top wants to drop on you, the sidewalls react to the removal of their support by trying to move into the shaft, the floor wants to equalize pressure by humping up, everything wants to go somewhere. Add to this the constant dripping or flowing of water from the top, the creaks and groans from the settling props and the unbelievable, total black dark of an underground mine and you have the atmosphere of terror for the uninitiated. And there is real danger, clear and present every moment you are there, everything can burn.

The Victory mine had the advantage of location. The slope for the drift was good,the seam was easily available and fairly level, there was a good step area on the slope for the tipple and, probably most important, there was enough land to the south to run a rail spur from the main line and enough flat land for a boxcar storage area.

The Victory was a drift mine, meaning that the main tunnel was driven slightly sloped upward into the coal seam so any water from the mine would flow out. This also meant that the loaded coal cars would have gravity working with them on the way out.

There were three coal seams at Wabamun but in underground mining only the nine foot thick one was taken. Miners would leave about a foot of coal overhead to protect from cave-ins.

Sequence of pillar and stall mining:

Sequence of pillar and stall mining:

Check HERE for a Glossary of some of the terms used.

An entrance was prepared in the hillside. The eight foot by eight foot drift was driven (dug) into the edge of the coal seam, it was propped, timbered and lagged to a safe standard. The drift continued, following the seam in a more or less straight line, ideally to the limit of the licence area. Tracks were laid and services provided for as the drift extended.

The airshaft was driven down from the surface to meet the drift, it was cribbed to standard, the fan installed and operated, and true mining could begin.

A gallery opening at the parting or first turnoff was widened to thirteen feet, double tracks were laid down and the bull wheel for the haulage rope was mounted at the upper end.

Parallel passageways were driven at ninety degrees to the drift, with a pillar of the appropriate size left between them. One of these was the working passageway, the other an airway. The air from the fan had to be maintained at all times for ventilation and occasional cross-openings were dug to aid in this.

Once the passageways had reached the end, generally at the limit of the licence area, mining by the pillar and stall method could begin in earnest. Parallel stalls were driven off the side opposite the airway,(probably about 60 feet apart) they were joined at their limit and the pillar between was mined out and removed starting at the back and moving toward the passageway, thus allowing the waste to fall behind the work as a support for the roof.

The coal mining ideal was to undermine the seam at the bottom, leaving a space for the coal face to drop. For many years this was done by the miner lying on his side at the bottom of the seam and swinging a pick as far as he could reach, supporting the undercut with wedges until the entire face was undermined. The wedges would then be pulled or knocked out and much of the seam would fall ready for loading. In the 1920's a coal cutting machinewas introduced. It was like a giant chainsaw with a six foot long bar which cut a six inch wide kerf at the bottom of the seam. It was mounted on the tracks and electrically powered.

Most of the coal at Wabamun was picked loose from the face so there was minimal blasting done.

Blasting was to loosen the coal as much as possible without breaking it up, as the only coal that paid was the stuff in large lumps. The art and science of the fireboss was to know how, where and how much TNT to use to get the maximum useful production from the coal face.

The miners drilled the holes in the face in a predetermined pattern and to the right depth. The fireboss then loaded these with the correct amount of TNT, cleared everyone out, then fired the shot which would loosen the coal so it could be scoop shovelled into the cars

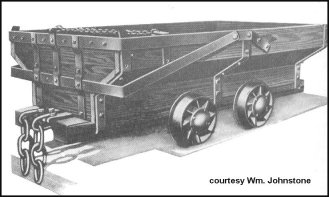

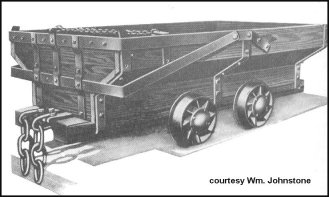

When the cars were loaded they were pulled by horses to the parting. The horses then pulled back the empty cars and the cycle started again.

Between laying and pulling up track in the passageways and stalls, undermining the coal face, loading cars and setting and pulling props and timbering, a miner put in a pretty full working day.

A trip of about twenty cars was made up to be hooked on the haulage rope and pulled out of the mine.

Return to Victory Coal Mine.

"Some Coal Links"

Carbide Lamps

In 1892, while working with a lime, coal tar and

carbon mixture, Major James T. Morehead and

Thomas L. Willson developed a brownish-grey

substance which they called carbide. When drops of water were added this generated acetylene gas which could be burned in a lamp to give a superior light. Within eight

years the first carbide lamp was offered and soon

after that, they were adapted for underground mining.

The first carbide mining lamps burned approximately four hours with a one-inch

flame. A three-inch reflector directed light of 10-foot-candle power. These lamps

could be carried or rested on any flat surface.

At the Victory mine the miners carried their lamps on a bracket on the front of the helmet.

In one sense coal mining is simple, you dig a hole in the coal and sell what you take out.

Realistically, digging an eight foot by eight foot by x foot hole under a pile of dirt, gravel and rock sixty to ninety feet deep becomes complicated quickly, especially if you want to keep breathing. The top wants to drop on you, the sidewalls react to the removal of their support by trying to move into the shaft, the floor wants to equalize pressure by humping up, everything wants to go somewhere. Add to this the constant dripping or flowing of water from the top, the creaks and groans from the settling props and the unbelievable, total black dark of an underground mine and you have the atmosphere of terror for the uninitiated. And there is real danger, clear and present every moment you are there, everything can burn.

In one sense coal mining is simple, you dig a hole in the coal and sell what you take out.

Realistically, digging an eight foot by eight foot by x foot hole under a pile of dirt, gravel and rock sixty to ninety feet deep becomes complicated quickly, especially if you want to keep breathing. The top wants to drop on you, the sidewalls react to the removal of their support by trying to move into the shaft, the floor wants to equalize pressure by humping up, everything wants to go somewhere. Add to this the constant dripping or flowing of water from the top, the creaks and groans from the settling props and the unbelievable, total black dark of an underground mine and you have the atmosphere of terror for the uninitiated. And there is real danger, clear and present every moment you are there, everything can burn. Sequence of pillar and stall mining:

Sequence of pillar and stall mining: