simple ceiling robots

A bit of polythene can be made to cling to a flat surface by vibrating it.

The polythene acts as a non-return valve: air squashed against the ceiling can get out from under the skirt but can't get back.

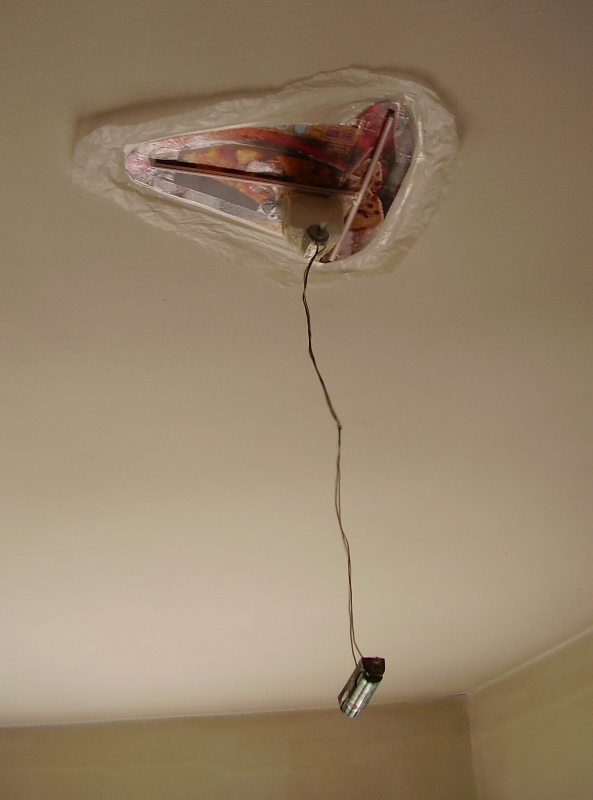

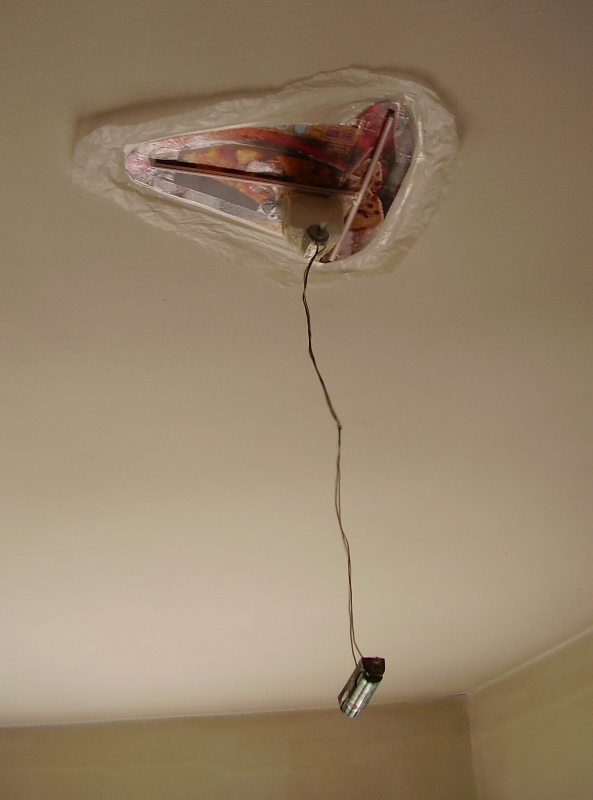

The vibrating mechanism in this case consists just of a motor driven by a single AA battery, a slip of card is sellotaped to the shaft of the motor and a small bit of blue tack stuck to the card.

The motor is taped to a bit of styrofoam which is taped to a bit of card which in turn is taped to the polythene. The card is reinforced with drinking straws to make it more rigid. The vibration of the motor has to be transfered to the card with as little loss as possible.

The battery hangs underneath to enable the top bit to act as a parachute when it falls off the ceiling, the leads are twisted round a bit of stiff wire to facilitate positioning the machine on the ceiling. This can be quite dangerous, especially for a child.

The easiest way to reach a ceiling is by a stair well but if one isn't available the ceiling can be surprisingly difficult to reach. A child will be tempted to improvise a method and will be distracted by the toy when balanced precariously on whatever it has decided to stand on.

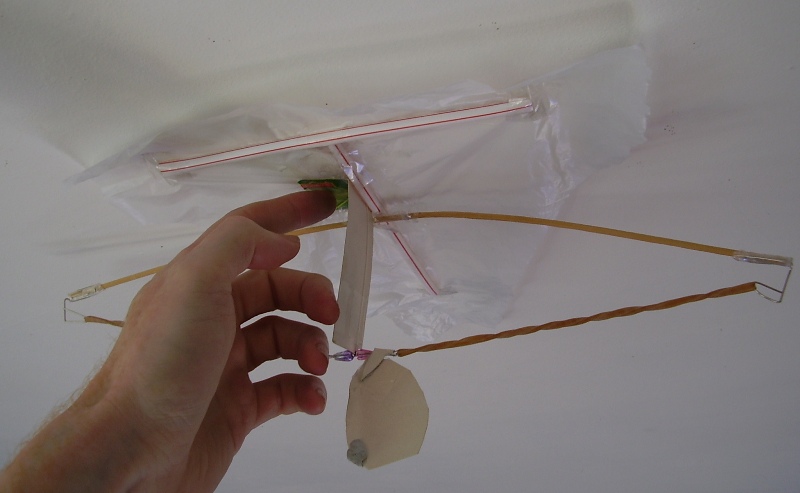

This is an earlier version made from a styrofoam plate

An underlying problem of the machines is maintaning a seal where the flexible polythene is taped to the rigid material. Really there needs to be some gradual change of flexibility between the two materials (see bottom of page). The sellotape tends to curl upwards (downwards) and this stops the machine clinging to the ceiling.

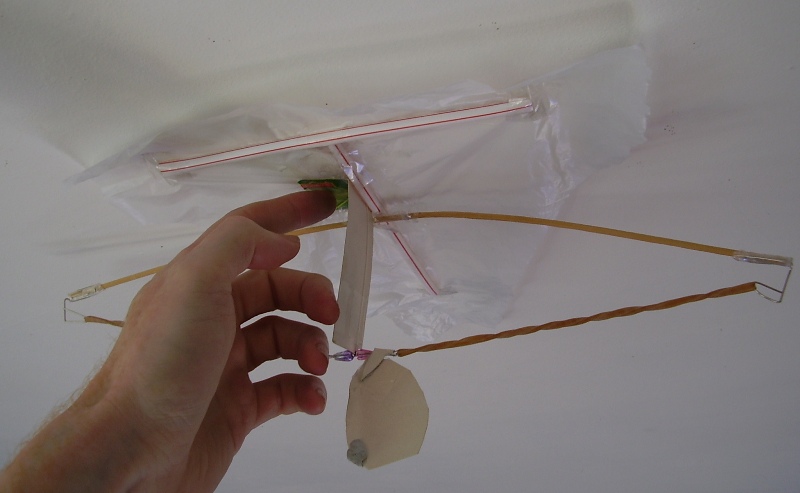

This is one powered by two rubber bands

The original version was made from a styrofoam plate; this one was invented in a pub in Brighton.

The spinning weight propels the machine as well as vibrating the polythene. I don't think there is any 'propellor' effect except that the flap of card slows down the rotation a bit and therefore makes it last longer.

This is a much better way of making the skirt

The spiky shape is cut from a bit of paper & taped to the polythene, the CD is then taped to the paper shape. This is what it looks like from underneath

This causes a gradual change in flexibility from the stiff CD to the floppy polythene. This turns out to be the key to preventing the seal from leaking. The effectiveness of the seal can be demonstrated by placing it flat on a table and pulling upwards repeatedly.

my email is davidvwilliamson@hotmail.com

back to main site