That investigation represents part of the most recent work related to these kinds of systems. Further discussion on how the system performs all the tasks can be seen in the theoretical framework of this work, since the project proposed will make use of this system for exchanging information, with some slight modifications, most of them in the data acquisition portion.

Now, in reference to data acquisition, the work developed by Kosuge [3], which represents the state of the art in force sensors for mobile robot systems, will be the used in this project. The sensor developed by those researchers differs from others in the way that it is located between the drive mechanism and the body of the mobile robot. This is a radical change, since the force feedback obtained represents not only the tips of the end-effector of the mobile robot, instead it makes the whole body of the robot sensitive to external forces. This allows better performance, because the control algorithms will now operate with complete information of the robot, not only the manipulator, and this results in a more stable motion when carrying an object, either alone or in cooperation with other robots.

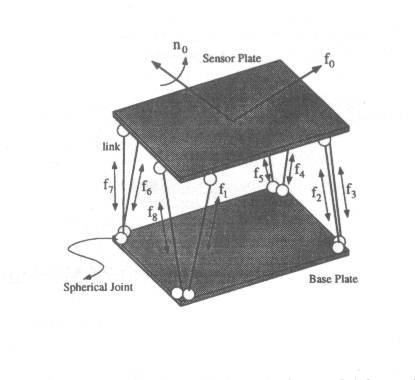

This device is built as shown in figure 1, and as seen, the approach for sensing forces is different, and it also allows to sense momentum. Again, in the theoretical framework a further discussion over the capabilities of this sensor will be exposed.

Fig. 1. Body Force Sensor [3]

As to the rest of the articles, they define some concepts that will be used in this project, for example SSA, which stands for Subsumption Control Architecture. This architecture works in different layers of control system in order to let the robot operate at increasing levels of competence. SSA is used by Hara [2] for a two mobile robot system designed to carry an object through a wavy road. This paper will be used just as a reference to the control system architecture, in the way that the my proposed project will work on layers. However, the main focus of this article [2], which is analysing motion in an irregular surface, will not take part of my work right now, since for reasons of simplification, the proposed project will be developed for work in a regular surface. This constraint is proposed due to the necessity of testing the robustness of the system before adding extra variables to the ones that are already expecting to be solved.

The paper written by Sasaki [4] will not be used at the moment since the proposed analysis is completely different from the one in that paper. The reason is that the force analysis developed in the article refers to cooperative handling of objects by "pushing robots" using contact points rather than grippers. In fact, the whole paper consists of an extensive mathematical analysis to determine the constraints of selecting contact points in the object from which the robots will cooperatively push by applying forces that will be strong enough to move the object and vectorially correct, to avoid rotating the object when not necessary, for example. As you can see, this aim is different from the project proposed in this work, mainly because of two reasons:

1. I intend to make use of force analysis, but for a different motion, because the project I propose is going to cooperatively lift an object rather than pushing it, so the vectorial force analysis diverges from what is exposed in [4].

2. The object considered for the actual proposal is an undeformable and regular object. This was done in order to simplify the analysis, however, it can easily be extended to an irregular object, such as the ones in [4].

Now, the project proposed aims to merge the systems proposed in [1] and [3], which are a robust communication system for cooperative working and a new approach on force sensors, in order to develop a more robust cooperative multirobot system.

Back to main

Theoretical Framework