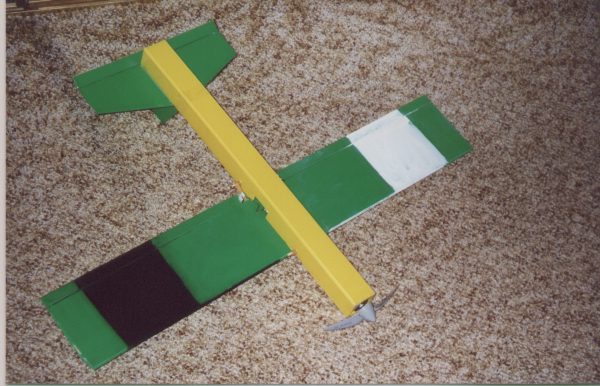

"Coros 400"

These instructions are probably a little confusing sorry, and I've probably forgotten something, but I made it up as I went along and I've only been flying since Febuary 2001 so you can probably make up whatever I've forgotten. E-mail me if you need further assistance. To convert millimetres to inches, divide by 25.4

|

|

Materials:

3mm Coroplast/Coreflute/Correx 2mm would probably also work, be lighter (and weaker) but this is what I used

6mm medium hard balsa

popsicle sticks

Hot glue/contact cement

medium CA

sandpaper

spirits/acetone

Sellotape I used 1.8cm wide tape

spring wire for control I actually used paperclips unfolded

bamboo skewer Mine was 3mm diameter.

nail/metal skewer

double-sided tape

Electronics:

6V speed 400 and prop of choice I used a Graupner 6*3 folder

2 servos of choice I used two HS-55s, I'd advise one HS-55 for the elevator and something larger like a HS-81 for ailerons

7*KR600AE or there abouts

suitable ESC

suitable receiver I used a JR610M

Instructions

First, measure and cut coroplast to the following dimensions:

Tail

This is the easiest bit. With the tail cut out as per dimensions above (the vertical tail is the non-symmetrical one of course) seal the edges with tape. Part the elevator from the stabiliser, it should be 6 flutes wide. Cut a slot in the centre of this and glue in your control horn. Use tape to hinge the elevator. Measure and mark the centreline on the horizontal stabiliser, use hot glue to attach the vertical stabiliser, make sure its at right angles to the horizontal stab. Cut a popsicle stick in half and then cut off the rounded ends, and use these to brace the tail join so it remains right-angled. Put this aside for later.

Fuselage

Fold this up into a box, but do not glue or tape it up yet.Choose a side to be the top (its easiest if you choose a side that has a bend either side, not one on the edge of the piece of coro!) and unfold. Mark four lines perpendicular to the length of the fuselage, on the top side, measured from the front with these distances: 128mm, 130mmm, 260mm, 270mm. The first and last lines should extend into the third flute of the adjactent sides. Mark two crosses on each adjacent side to the top side, in the centre of the thrid flute from the bend, and on the lines that extend onto them. Using a nail or metal skewer punch holes at these marks, and widen so the bamboo skewer will fit snugly in the holes. When the fuselage is assembled these will become the holes through which the skewer will go, for the rubber wing hold-down bands to be secured from. Cut away the portion of the top side between the second and third lines, this will be your wing mounting area. Keep the scrap in a handy spot, its useful later. Cut away the portion of the top between the front and the second line (leaving no plastic between the front to the third line), this has to go back on later so make sure you know where it is.

Take some popsicle sticks. Test fold the fuz into a box and measure the inside diagonal distance. Cut four pieces of popsicle stick to this length. In the middle of each cut a slot, as wide as a popsicle is thick. Slot these together, forming two crosses. These will be braces for the fuselage. Fold the fuselage up again, with the braces positioned at 80mm from the front and 360mm from the front. Do not close the final side yet. Glue the braces in place, then close the final side and glue that to the braces as well. Then run a bead of glue the entire length of the join and strap with tape. I used hot glue. Cut two pieces of bamboo skewer, each 80mm long. Push these through the holes in the fuselage you made earlier and make it so each end pokes out an even distance (looks neater), then glue in place with hot glue.

Almost done!

Take the two pieces of plastic you cut off the top earlier. Lay the scrap piece perpendicular to the piece from the nose, and cut a piece wide enough that it will fit snug between the fuselage sides. Glue this to the piece from the nose, centred, so that the flutes run perpendicular to each other. You should find that you can now slot this back onto the fuselage (added bit on the inside of the fuse), with a nice snug fit. Lay this down on a table with the added bit upwards, and position a speed 400 motor over this, with the can poking out the front 2 or 3mm. Mark two lines either side of the can, and cut slots here all the way through, long enough to take a nylon cable tie. You've just made your motor mount. Put your propeller on your motor and solder your ESC and suppresion capacitors and diode in place. Attach the motor to the mount using two cable ties, make sure its nice and tightly attached. I found that by tightening the rear tie more than the front one I could give the motor some down thrust - this is a good thing, so put in about 2 or 3 degrees of this. I also tilted the motor right about the same amount. My ESC has an arming switch so I cut a hole in the mount and put the switch through that. Now thread the cables of the ESC through the cross of the popsicle sticks and fit the mount/nose piece of the model back on the fuselage. I hot glued this for the entire length on both sides, and then taped it as well. I then put tape over the open flutes at the front of the fuselage.

Finishing

Decorate as you see fit. I used automotive spray paint.

Final Assembly and Equipment Installation

Glue your tail to the back of the fuselage with hot glue (this glue will pull away if enough force is applied, so the tail will snap clean off in a crash instead of anything else being damaged). I cut a hatch in the top of the fuselage, hinged with tape, just behind the rear wing hold-down post and installed my elevator servo there using double-sided tape. I made my control runs out of unfolded paper-clips. For the elevator I needed to join two together, I used heat-shrink tubing, wrapped it with strong thread and CA'd the lot.

I secured the battery using velcro straps, but use your favourite method. Putting foam blocks in front and behind the battery would be a good idea. I found that I needed to put the battery almost as far forward as it would go to get the CG I flew it with. Wrap the receiver with foam or bubble wrap and put that between the battery pack and the elevator servo. I dropped the antenna out the hole at the back.

I mounted my aileron servo upside-down in the wing so I needed to make my battery pack flat so the arms could move above it. I cut holes in the sides of the fuselage for the controls to pass through, these turned out to be the weak point of the design when I eventually did a full-speed crash and the fuselage bent so I'd advise gluing some balsa or scraps of coroplast on the sides around the wing mount.

I attached the wing using 4 size no 64 rubber bands, two diagonal and two parallel to the fuselage.

Control throws:

Approx 40 degrees both ways for all surfaces.

CG:

On the spar of the wing, mine was near the back.

Weight:

Mine came out a smidge over 15oz (425g).

Flying

Take it to your flying field, turn on your transmitter, plug in your aileron servo and your battery, attach the wing, flick the arming switch, check your surfaces go in the right direction, and do a quick range check. Pick the little plastic thing up, hold under the wing, advance the throttle, and give it a bit of a heave. You don't need to throw it very hard at all. I did a couple of circuits around the field just getting the trims right, then landed and passed these settings over to the electronic sub-trim so I could centre the mechanical trims again. Launch again, climb to a nice height and do your worst. The speed of this model is not too high, it was fine for me and this is my first model that was faster than an indoor model. It handles very nice, goes where you point it. For maximum excitement fly low and fast, with biiiig banked turns - they look very cool. Landing is easy, cut the motor (or let the BEC kick in), and pull the elevator stick back until you find the point where you can glide nicely - sink rate not too fast, slightly nose-up attitude. Maintain this attitude with the wings level for the last few feet of the final approach and it will skid along the grass nicely. Don't be afraid to punish this model, its very durable. I cartwheeled mine across the ground several times with no damage caused. They can break if you nose it in at full throttle after a bit of a dive though, I found out the hard way :S

Enjoy your model.

If you do choose to build this model, by all means send me pictures and details.

NEW: Here is the spreadsheet I used to decide on my dimensions before building. It calculates wing loading and power loading based on your specs. Ideal if you are going to upsize it for different power systems.Download it!

Home

I take no responsibilty for any damage to equipment or harm of living creatures caused by following these instructions. Copyright 2001 Tristan Williams

3mm Coroplast/Coreflute/Correx 2mm would probably also work, be lighter (and weaker) but this is what I used

6mm medium hard balsa

popsicle sticks

Hot glue/contact cement

medium CA

sandpaper

spirits/acetone

Sellotape I used 1.8cm wide tape

spring wire for control I actually used paperclips unfolded

bamboo skewer Mine was 3mm diameter.

nail/metal skewer

double-sided tape

Electronics:

6V speed 400 and prop of choice I used a Graupner 6*3 folder

2 servos of choice I used two HS-55s, I'd advise one HS-55 for the elevator and something larger like a HS-81 for ailerons

7*KR600AE or there abouts

suitable ESC

suitable receiver I used a JR610M

Instructions

First, measure and cut coroplast to the following dimensions:

The grey lines indicate scoring positions. To do this

use a screwdriver with a blunt tip (if its a sharp tip it will cut the plastic)

and crush the top part of the flutes at these stations. The double line

in the wing is where you should crush two adjacent flutes.

Wing

Cut a piece of 6mm balsa, 15mm wide and 762mm long (grain lengthwise). This will be the spar of your model. It was fine for me, but you may wish to use something stronger like spruce. The rear of the spar goes 83mm from the TE of the wing (bottom line in diagram above). To attach the spar, sand the area that you wish to glue it to, rub it down with spirits or acetone on a clean cotton cloth. Do the same on the segment of the wing that is 15mm wide (that will attach to the top of the spar). Use medium CA to glue the spar on the bottom segment of the wing (the 127mm one), make sure it is square all along. The rear of the spar should be 83mm in front of the TE of the wing. When dry, fold the wing over so the 15mm segment is positioned directly over the spar, and glue this down. It is a good idea to clamp it and let it dry totally. For the trailing edge I used contact cement and tacked in 4 places with hot glue, and put a nylon cable tie in the centre. You don't want this coming un-stuck! Make your ailerons 5 flutes wide, 347mm long. I made a 10mm gap between the aileron inner edge and the remaining centre section, so the rubber bands for wing fastening don't interfere with the ailerons. Part the ailerons from the wing, and hinge with tape. Make up some control horns and attach them to your ailerons. Cut a hole slightly smaller than your servo in the wing, push-fit it in, and set up controls. I put a V-shaped bend in the centre of my aileron control rods so I could adjust each individually. I put the servo in upside-down so the bottom poked out the top a few millimetres, and then used tape to streamline where the servo came out. Reinforce the centre bit of remaining trailing edge with 50mm long pieces of popsicle stick running perpendicular to the wing span (otherwise it collapses in flight). Use tape to seal the ends of the wing to prevent unneccessary drag. Done.

Wing

Cut a piece of 6mm balsa, 15mm wide and 762mm long (grain lengthwise). This will be the spar of your model. It was fine for me, but you may wish to use something stronger like spruce. The rear of the spar goes 83mm from the TE of the wing (bottom line in diagram above). To attach the spar, sand the area that you wish to glue it to, rub it down with spirits or acetone on a clean cotton cloth. Do the same on the segment of the wing that is 15mm wide (that will attach to the top of the spar). Use medium CA to glue the spar on the bottom segment of the wing (the 127mm one), make sure it is square all along. The rear of the spar should be 83mm in front of the TE of the wing. When dry, fold the wing over so the 15mm segment is positioned directly over the spar, and glue this down. It is a good idea to clamp it and let it dry totally. For the trailing edge I used contact cement and tacked in 4 places with hot glue, and put a nylon cable tie in the centre. You don't want this coming un-stuck! Make your ailerons 5 flutes wide, 347mm long. I made a 10mm gap between the aileron inner edge and the remaining centre section, so the rubber bands for wing fastening don't interfere with the ailerons. Part the ailerons from the wing, and hinge with tape. Make up some control horns and attach them to your ailerons. Cut a hole slightly smaller than your servo in the wing, push-fit it in, and set up controls. I put a V-shaped bend in the centre of my aileron control rods so I could adjust each individually. I put the servo in upside-down so the bottom poked out the top a few millimetres, and then used tape to streamline where the servo came out. Reinforce the centre bit of remaining trailing edge with 50mm long pieces of popsicle stick running perpendicular to the wing span (otherwise it collapses in flight). Use tape to seal the ends of the wing to prevent unneccessary drag. Done.

This is the easiest bit. With the tail cut out as per dimensions above (the vertical tail is the non-symmetrical one of course) seal the edges with tape. Part the elevator from the stabiliser, it should be 6 flutes wide. Cut a slot in the centre of this and glue in your control horn. Use tape to hinge the elevator. Measure and mark the centreline on the horizontal stabiliser, use hot glue to attach the vertical stabiliser, make sure its at right angles to the horizontal stab. Cut a popsicle stick in half and then cut off the rounded ends, and use these to brace the tail join so it remains right-angled. Put this aside for later.

Fuselage

Fold this up into a box, but do not glue or tape it up yet.Choose a side to be the top (its easiest if you choose a side that has a bend either side, not one on the edge of the piece of coro!) and unfold. Mark four lines perpendicular to the length of the fuselage, on the top side, measured from the front with these distances: 128mm, 130mmm, 260mm, 270mm. The first and last lines should extend into the third flute of the adjactent sides. Mark two crosses on each adjacent side to the top side, in the centre of the thrid flute from the bend, and on the lines that extend onto them. Using a nail or metal skewer punch holes at these marks, and widen so the bamboo skewer will fit snugly in the holes. When the fuselage is assembled these will become the holes through which the skewer will go, for the rubber wing hold-down bands to be secured from. Cut away the portion of the top side between the second and third lines, this will be your wing mounting area. Keep the scrap in a handy spot, its useful later. Cut away the portion of the top between the front and the second line (leaving no plastic between the front to the third line), this has to go back on later so make sure you know where it is.

Take some popsicle sticks. Test fold the fuz into a box and measure the inside diagonal distance. Cut four pieces of popsicle stick to this length. In the middle of each cut a slot, as wide as a popsicle is thick. Slot these together, forming two crosses. These will be braces for the fuselage. Fold the fuselage up again, with the braces positioned at 80mm from the front and 360mm from the front. Do not close the final side yet. Glue the braces in place, then close the final side and glue that to the braces as well. Then run a bead of glue the entire length of the join and strap with tape. I used hot glue. Cut two pieces of bamboo skewer, each 80mm long. Push these through the holes in the fuselage you made earlier and make it so each end pokes out an even distance (looks neater), then glue in place with hot glue.

Almost done!

Take the two pieces of plastic you cut off the top earlier. Lay the scrap piece perpendicular to the piece from the nose, and cut a piece wide enough that it will fit snug between the fuselage sides. Glue this to the piece from the nose, centred, so that the flutes run perpendicular to each other. You should find that you can now slot this back onto the fuselage (added bit on the inside of the fuse), with a nice snug fit. Lay this down on a table with the added bit upwards, and position a speed 400 motor over this, with the can poking out the front 2 or 3mm. Mark two lines either side of the can, and cut slots here all the way through, long enough to take a nylon cable tie. You've just made your motor mount. Put your propeller on your motor and solder your ESC and suppresion capacitors and diode in place. Attach the motor to the mount using two cable ties, make sure its nice and tightly attached. I found that by tightening the rear tie more than the front one I could give the motor some down thrust - this is a good thing, so put in about 2 or 3 degrees of this. I also tilted the motor right about the same amount. My ESC has an arming switch so I cut a hole in the mount and put the switch through that. Now thread the cables of the ESC through the cross of the popsicle sticks and fit the mount/nose piece of the model back on the fuselage. I hot glued this for the entire length on both sides, and then taped it as well. I then put tape over the open flutes at the front of the fuselage.

Finishing

Decorate as you see fit. I used automotive spray paint.

Final Assembly and Equipment Installation

Glue your tail to the back of the fuselage with hot glue (this glue will pull away if enough force is applied, so the tail will snap clean off in a crash instead of anything else being damaged). I cut a hatch in the top of the fuselage, hinged with tape, just behind the rear wing hold-down post and installed my elevator servo there using double-sided tape. I made my control runs out of unfolded paper-clips. For the elevator I needed to join two together, I used heat-shrink tubing, wrapped it with strong thread and CA'd the lot.

I secured the battery using velcro straps, but use your favourite method. Putting foam blocks in front and behind the battery would be a good idea. I found that I needed to put the battery almost as far forward as it would go to get the CG I flew it with. Wrap the receiver with foam or bubble wrap and put that between the battery pack and the elevator servo. I dropped the antenna out the hole at the back.

I mounted my aileron servo upside-down in the wing so I needed to make my battery pack flat so the arms could move above it. I cut holes in the sides of the fuselage for the controls to pass through, these turned out to be the weak point of the design when I eventually did a full-speed crash and the fuselage bent so I'd advise gluing some balsa or scraps of coroplast on the sides around the wing mount.

I attached the wing using 4 size no 64 rubber bands, two diagonal and two parallel to the fuselage.

Control throws:

Approx 40 degrees both ways for all surfaces.

CG:

On the spar of the wing, mine was near the back.

Weight:

Mine came out a smidge over 15oz (425g).

Flying

Take it to your flying field, turn on your transmitter, plug in your aileron servo and your battery, attach the wing, flick the arming switch, check your surfaces go in the right direction, and do a quick range check. Pick the little plastic thing up, hold under the wing, advance the throttle, and give it a bit of a heave. You don't need to throw it very hard at all. I did a couple of circuits around the field just getting the trims right, then landed and passed these settings over to the electronic sub-trim so I could centre the mechanical trims again. Launch again, climb to a nice height and do your worst. The speed of this model is not too high, it was fine for me and this is my first model that was faster than an indoor model. It handles very nice, goes where you point it. For maximum excitement fly low and fast, with biiiig banked turns - they look very cool. Landing is easy, cut the motor (or let the BEC kick in), and pull the elevator stick back until you find the point where you can glide nicely - sink rate not too fast, slightly nose-up attitude. Maintain this attitude with the wings level for the last few feet of the final approach and it will skid along the grass nicely. Don't be afraid to punish this model, its very durable. I cartwheeled mine across the ground several times with no damage caused. They can break if you nose it in at full throttle after a bit of a dive though, I found out the hard way :S

Enjoy your model.

If you do choose to build this model, by all means send me pictures and details.

NEW: Here is the spreadsheet I used to decide on my dimensions before building. It calculates wing loading and power loading based on your specs. Ideal if you are going to upsize it for different power systems.Download it!

Home

I take no responsibilty for any damage to equipment or harm of living creatures caused by following these instructions. Copyright 2001 Tristan Williams