|

|

|

||

| MANUFACTURE |  |

|||

Carbon fibre is made in a specific way, and this page will try to explain some of the complex processes in its manufacture.

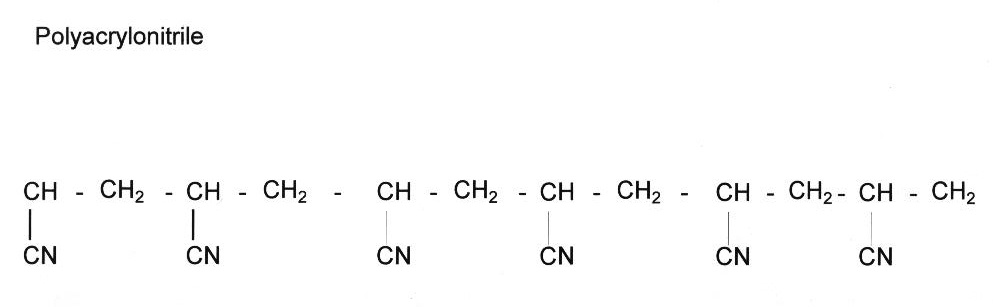

Carbon fibre is manufactured from a core material called Polyacrylonitrile (PAN).

|

This picture is the molecular structure of PAN - note the weak shape the molecule forms. It is this ladder shape which needs to be converted into a stronger molecule.

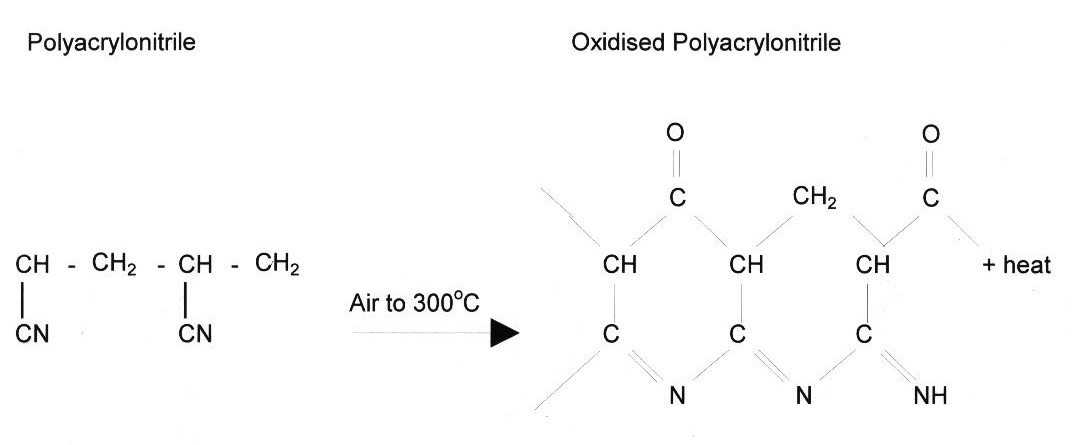

In order to change PAN into carbon fibres, a series of stages needs to be followed. First the PAN is oxidised (heated in air). This breaks the molecule into different elements, which form new bonds with oxygen. The picture below shows the change of molecule.

It is at this stage where the PAN fibres (originally white) darken until they are the familiar carbon fibre black (see below).

This new material is still not carbon

fibre - at this stage it is PANOX - a fireproof textile fibre.

This new material is still not carbon

fibre - at this stage it is PANOX - a fireproof textile fibre.

|

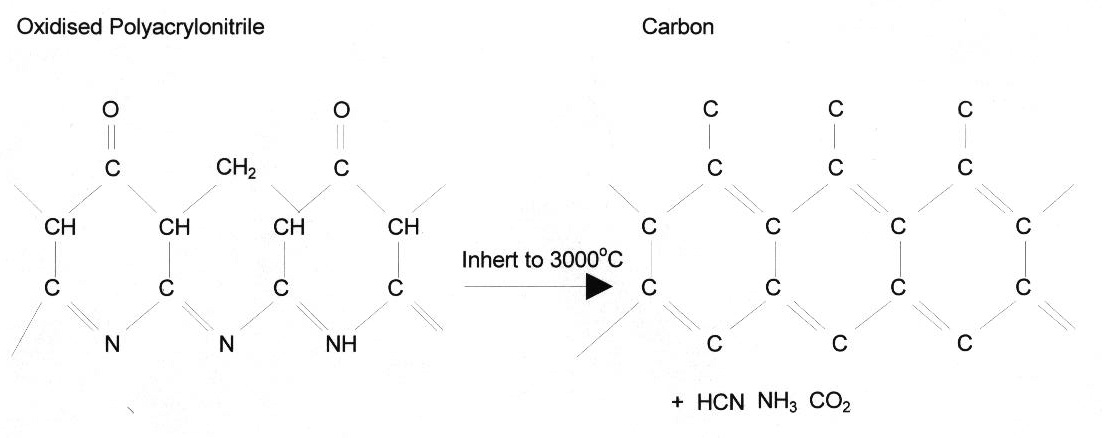

This materialis strong, but since there are many foreign atoms in the fibre's structure, a mixture of strong and weak bonds are inherant in the material. In order to purify the material into carbon fibre, it is CARBONISED at 3000oC to change the other atoms (such as nitrogen and oxygen) into pure carbon atoms.

|

This image shows the final stage in carbon fibre's construction, where almost 100% of the atoms are now carbon. The double bonds which the carbon forms, together with its hexagonal shape, give the carbon fibre its incredible strength. |

The now complete carbon fibre can be added to resin or a polymer to make a strong composite material - which has a wide range of applications. Look at the aircraft section of the site to see how carbon fibre is used in aircraft.