Here's my 1989 B12 Sentra Stationwagon. It was a pretty good car. Reliable, sensible engineering, utterly conventional in every respect. Hey it's a Nissan, and you can't ask for better than that. Anyway I decided it had to have a bigger engine. It seems to be the tradition in my family. Buy some boring car, then hotrod it. Then sell it and buy an R32 GTR. (Well no-one bought the GTR yet, but we all seem to end up with turbo Nissans.)

So there was a bit of research needed, as this is not a commonly modified car. The original engine was a GA14S, 1400cc, 12 valves, SOHC, carburetted. What could go in its place? Sentras of the time did come as a coupe with a CA18 in them. I did consider this. But CA18s are now getting pretty tired and old, plus it turned out they didn't mate up to my gearbox. An SR20 would seem quite desirable, but quite a squeeze, and again, gearbox wouldn't work. There were the turbo EXAs with the E15ET, but again old tired motors. I found out that the GA motors were modified a bit in the US, and that the later GA motors were DOHC, NVCS (variable cam timing), 16 valve little beauties. We don't see these motors much in NZ, for some reason there are a lot of GA15s, DOHC, but carburetted! Well that's just bizarre.

So it was off to see what a bit of nepotism could do. I was able to get a GA16DE + loom + computer for a fairly reasonable price, and I interrupted Dad's holidays to borrow his skills and workplace.

Here's the GA14S just about to be ejected. The battery, air filter, radiator, starter motor, and loom are disconnected. The drive shafts still have to come out.

The GA14S on the hoist about to say goodbye to the gearbox.

A clean empty engine bay awaiting DOHC NVCS power.

A fresh GA16DE from the wreckers, looking for a new home. This had a bit of preparation earlier. The power steering and air conditioner pumps were binned, as my car has neither. This meant it was possible to run the water pump and alternator off one belt, but the alternator had to be moved slightly. Dad modified the alternator bracket to suit, and found a Honda belt that would fit. The engine was absolutely immaculate internally. You can see that it's from an automatic car, as there's no flywheel. You can also see the cat exposed as the exhaust manifold cover was missing, and that the exhaust manifold has separate passages for each cylinder all the way to the cat. (For some reason US manifolds combine the exhaust ports into two pairs straight out of the head.) I ended up using the manifold cover from my old engine, with a new hole for the dipstick.

A mixture of clutches and flywheels. I knew my thrust bearing was pretty worn before we started, so we had a new one, but when we pulled everything apart, we found the clutch also was worn just about down to the rivets. We had a sort of second-hand clutch/flywheel/pressure plate from a GA16, as we were kind of expecting this. You can almost see from the picture that the GA14 flywheel (left) is quite a bit lighter than the GA16 flywheel. We thought that we were going to be able to use the old flywheel so as to have a lightened flywheel. Unfortunately, when we put the new clutch into the old flywheel/pressure plate, we found that the new thrust bearing didn't match the old pressure plate, so we had to use the GA16 flywheel after all. Bugger. So now I've got the old flywheel lying around just in case. But I doubt we'll ever be in there again.

At the end of the first day we have an engine in place. Obviously the gearbox mount was OK because it's the same gearbox. The front and rear mounts were identical. The right mount was completely different, so now it's just sitting there. The exhaust from the GA16 has been welded onto the car's exhaust. It was originally 1.75" and now it's been necked down to the 1.5" of the car, but hey we just have to get the engine in there and going, we can worry about that shit later. The loom is draped over the engine.

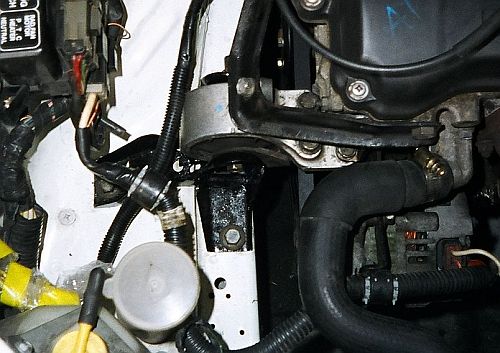

Here's the new right engine mount. Dad made it out of pieces of the old GA14 one and the new GA16 one. In cars with a GA16 factory, the round aluminium mount bolts into a cradle formed in the car body, there's no extra mount. You can see the alternator there too. We ended up having to use the old GA14 alternator, as the new one wouldn't fit the plugs on the car's loom. You can't quite see the new belt run.

New engine in car, car having driven itself to this location. I was pretty stressed about getting the computer wired up. But it worked pretty much first time. I had several wiring diagrams, all a bit different. Luckily one of them matched the colours on the wires we had. It turned out that the engine was a 1997 model. This is kind of good, because it's the last one that had a remappable computer, but it had all the refinements in camshaft, ports, etc. that the later models had.

It only took the connection of two wires to make the motor run. (Well after sorting out the charging system, instrumentation, and engine connections, it only took two wires.) One wire is White/Blue Stripe and should be live all the time. It powers the computer and ECCS relay. The other wire is Black/Red Stripe and is live when the engine is on or start. It powers the injectors, the ignition, and a few sensors. Both of these wires can be found on the connector next to the computer on the loom.

If you want the emissions control and NVCS to work you need to power the brown wire on the same connector. This engine doesn't have any active emissions control, but the idle control solenoid and NVCS solenoid are on that wire. I tried running the engine with and without NVCS. The difference is very subtle, I don't know that it does much at all.

Here's the computer, the ECCS relay, various fuses, a switch to turn it all on, and some unused connectors lying in the passenger footwell. There's a cable heading back to supply the new fuel pump from a Toyota MkII (the car never had an electric fuel pump). The wiring has since been tidied up, but the computer is still loose. It needs some kind of enclosure up under the dash. (I did eventually mount it under the dash). The car needs a proper fuel tank from an injected car too, as the fuel surges when the level is low. I also ran a new fuel line from the tank to the engine bay, I already had a send and return, but they were both 1/4" and I went 5/16" for the send, if I recall correctly.

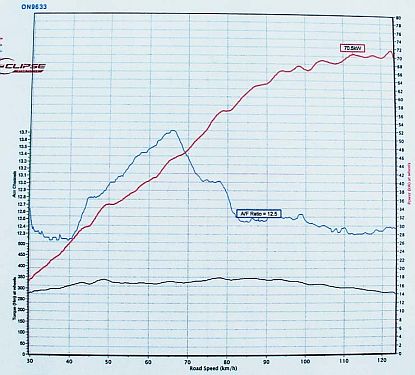

The lie detector. The engine is making 100BHP at the wheels, even with that restrictive exhaust and no mods. It doesn't have to turn the A/C or power steer pumps now of course. It's a pretty light car (almost exactly 1000kg), so it goes pretty hard, and look at the torque curve. The dyno was an Eclipse, and had compensation for temperature, air pressure, and humidity on the day, but hey no two dynos are ever the same. You can see the torque dropping off to the right, I'm sure that's the effect of the stifled exhaust.

Oh BTW, I read a lot of shit about how if you change the fuel pump all your fuel maps will be out. Well here's a fuel pump from a 1JZ and guess what? - the A/F ratio is spot on. Honestly what do these people think the fuel pressure regulator does? The engine idles at about 18:1 or 19:1, and under full load is about 12.5:1.