A Hunter 37 Cutter is built like a lot of boats. The cockpit is a large cavity supported only around the edges. In adition, these edges are perforated by all the openings to the lazerettes. When it is filled with water when you are pooped, it may not be up to the strain of all that weight.

In addition, Many boats are lost when a line gets into the prop, ripping the propshaft strut out of the bottom of the boat.

My solution to both these problems was to build a watertight bulkhead at the back of the cockpit, just forward of the propshaft strut.

To do this required cutting out the old bulkhead, which didn't go to the bottom of the cavity and was punctured with many holes. In addition, I had to cut away a bit of the rear of the deck inside the boat, under the cockpit, to get the propshaft strut bolts exposed.

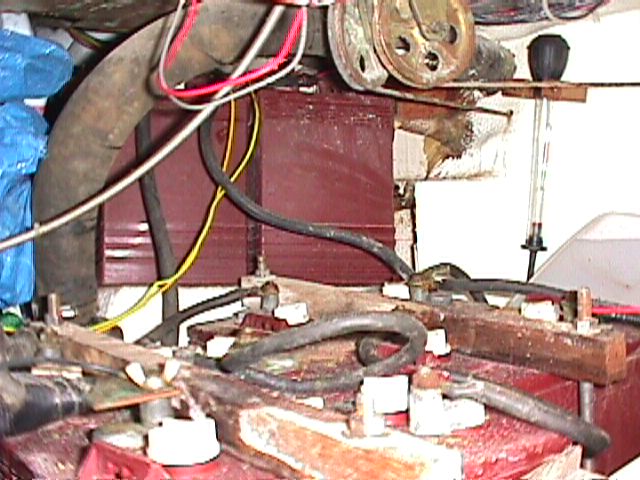

Then new plywood was glassed in, making a completely watertight barrier to the bottom of the cockpit. This was glassed in pretty strongly.

The muffler, which used to go straight back, was replaced with an uplift muffler and the exhaust hose was run through the top of the bulkhead. It was then sealed with sealant.

The steering cables are routed through the bulkhead, through holes just big enough for them. A small trickle of water could go around them, but they are above the waterline, so should have little effect. In addition, the fuel fill and vent hose had to be re-routed.

One more slight addition has proven quite handy. The propshaft strut bolts have been replaced with bolts that have a 1/4" stainless rod welded to the top, going at about a 90 degree angle. The rods are long enough that they hit the side of the cavity before turning all the way around. I put them in from the top, then I can put the nuts on from the bottom singlehanded. I can actually take the propshaft and strut out and replace it without help - in the water.