On the 26th, we took a 20 minute dinghy ride from Port Egmont to Mt. Hartman Bay so that we could take a sightseeing tour with five other cruisers. Unlike our trip in St. Lucia (see CruiseNews 24), this time we got a real tour guide, named Elvis. We had seven passengers in a van with 14 seats, so we had room to spread out and enjoy ourselves.

St. George, Grenada has a Mediterranean flavor

Elvis first took

us on an overlook of the capitol of Grenada, St. Georges, and then north

along the west coast. We passed a settlement of small identical weathered

wooden shacks, which Elvis called "Janet houses", and so named because

they were built by the Grenadine government after hurricane Janet destroyed

much of the housing on the island.

Elvis first took

us on an overlook of the capitol of Grenada, St. Georges, and then north

along the west coast. We passed a settlement of small identical weathered

wooden shacks, which Elvis called "Janet houses", and so named because

they were built by the Grenadine government after hurricane Janet destroyed

much of the housing on the island.Swimming in the pool at Concord Falls

Our first stop

was at the Concord waterfall, where we changed into our swimming suits

and plunged into the 40-foot-deep pool at the base of the falls.

Much refreshed by the cool fresh water, we climbed back into the bus and

rode through the lush Grenadine countryside.

Our first stop

was at the Concord waterfall, where we changed into our swimming suits

and plunged into the 40-foot-deep pool at the base of the falls.

Much refreshed by the cool fresh water, we climbed back into the bus and

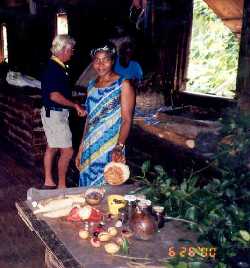

rode through the lush Grenadine countryside.Nutmeg, cocoa, bay leaves, cinnamon, calabash, and loofas are laid out for our inspection

Our next few stops

were an excellent example of why Grenada is called The Spice Island.

We stopped at a small spice farm and factory, where we were given a tour

by one of the workers. The "factory" itself is no more than a wooden

shed raised up off the ground several feet. Outside the shed on one

side were large wheeled drying trays, perhaps 15 feet square, which were

situated on rails so that they could be pushed under the shed when it rained,

thus keeping the spices dry. Inside the shed, we were shown how nutmeg

looks in its various stages: a small peach-like fruit which splits

open and allows the nut to drop to the ground; the red stringy covering

of the nut which is peeled off, sorted by quality, and which dries to yield

the yellow spice called mace; and the dark brown nut which is dried before

shipping, which is later cracked open and the nut ground for nutmeg.

Our next few stops

were an excellent example of why Grenada is called The Spice Island.

We stopped at a small spice farm and factory, where we were given a tour

by one of the workers. The "factory" itself is no more than a wooden

shed raised up off the ground several feet. Outside the shed on one

side were large wheeled drying trays, perhaps 15 feet square, which were

situated on rails so that they could be pushed under the shed when it rained,

thus keeping the spices dry. Inside the shed, we were shown how nutmeg

looks in its various stages: a small peach-like fruit which splits

open and allows the nut to drop to the ground; the red stringy covering

of the nut which is peeled off, sorted by quality, and which dries to yield

the yellow spice called mace; and the dark brown nut which is dried before

shipping, which is later cracked open and the nut ground for nutmeg.

Pushing in the drying racks for a passing shower

We also saw cloves,

which come from the bush looking like fire-engine-red candy corns.

As they dry they become the shape we are familiar with. We saw cocoa,

which begins as a red or yellow fruit filled with a sticky, gooey white

pulp. Inside the pulp are the cocoa beans, which are removed and

dried. We saw branches of a cinnamon tree's outer bark stripped off

and discarded, and how the inner bark is peeled off and saved. We

saw and smelled fresh bay leaves before they were dried. The spice

farm also grows loofas, which are not an aquatic sponge as we had always

thought.

We also saw cloves,

which come from the bush looking like fire-engine-red candy corns.

As they dry they become the shape we are familiar with. We saw cocoa,

which begins as a red or yellow fruit filled with a sticky, gooey white

pulp. Inside the pulp are the cocoa beans, which are removed and

dried. We saw branches of a cinnamon tree's outer bark stripped off

and discarded, and how the inner bark is peeled off and saved. We

saw and smelled fresh bay leaves before they were dried. The spice

farm also grows loofas, which are not an aquatic sponge as we had always

thought.

From there we went on to one of the nutmeg co-ops, where nutmeg is dried, sorted for size, cracked, graded and packaged in large burlap sacks. We also saw a cocoa factory, which takes the cocoa bean (the fruit and pulp having been discarded by the growers), dries it, polishes the outer shell, then sorts and grades it before again packing it away in burlap bags. We stopped at a bamboo goods shop, where bamboo is made into knickknacks for tourists from more traditional baskets, brooms, and chairs to lampshades and models of jet airplanes. By then we were all hungry, and were glad to stop for lunch at a local restaurant.

Water-powered sugar mill

After lunch, we

toured a rum factory. Unlike the one we saw in Martinique, this rum

factory used much the same methods as when rum was first made here.

The original water wheel and crushing machinery made in 1785 are still

used to crush the cane. The cane is fed into the crusher by hand.

The juices run into evaporation vats, which are heated by cane furnaces

stoked by hand. After fermenting, the juice runs into a distiller

heated by a wood fire. Bottling is perhaps the most "modern" part of the

process: The distillate (150 proof rum) is poured through a T-shirt

filter into several plastic coolers where workers use the spigot at the

bottom to fill the bottles. Twelve days after being crushed from

sugar cane, the bottled rum is "ready to drink", though our rum tasting

at the end of the tour leaves that contention somewhat a matter of opinion.

After lunch, we

toured a rum factory. Unlike the one we saw in Martinique, this rum

factory used much the same methods as when rum was first made here.

The original water wheel and crushing machinery made in 1785 are still

used to crush the cane. The cane is fed into the crusher by hand.

The juices run into evaporation vats, which are heated by cane furnaces

stoked by hand. After fermenting, the juice runs into a distiller

heated by a wood fire. Bottling is perhaps the most "modern" part of the

process: The distillate (150 proof rum) is poured through a T-shirt

filter into several plastic coolers where workers use the spigot at the

bottom to fill the bottles. Twelve days after being crushed from

sugar cane, the bottled rum is "ready to drink", though our rum tasting

at the end of the tour leaves that contention somewhat a matter of opinion.

On the way back, we had a quick stop at a national park before returning to the marina. Since we had a 20-minute dinghy ride through unmarked reefs, we had to leave before dark in order to make it back to the boat.

Not much else has been going on here. We went to a beach barbecue on Hog Island last night ($4 for a chicken dinner) where they had a nice steel band playing. Today we are going into town to see if we can find some ground beef, hot dogs, and maybe watermelon to celebrate the 4th of July tomorrow. In the next week or so we plan to head to Trinidad, where we hope to find parts for the boat that have not been available in the rest of the islands. Happy Independence Day to all!

Smooth Sailing,

Jim and Cathy