You will Need:

1 Crossbow Grizzly (part 1225)*

1 Pin 1mm across

30mm Balsa Strip 1mm x 1.5mm

1 Hex Base

2 Frag Cannons (from Assault Weapons 1403)

1 VHAC (from Support Cobra**

1311)

5/16" length of round Molding Sprue hollowed out to fit around

pin

1 Steel Rod 1/16" x 16" (or a HRP/24 from King Cobra 1313)

Lead*** (only a small

quantity is needed)

Dikes (for cutting steel rod)

Dremel Rotary Tool

X-Acto knives

Removal of LMG from Chassis

Addition of FGCs to Chassis

Replacing of HAC with VHAC

Creation of 'Mohawk'

Creation of VibroAxe

Creation of HRP/24

Adding the Frag Cannons

Begin by removing the LMG from the right lower torso

of the Grizzly chassis. The 2 hardpoints molded on the chassis

may also be removed. Next cut the FGCs off at the chamber, and remove

the magazine tubes. File down the bottom of the pump to about half

it's original height, slightly rounding the corners. Apply superglue

to the Grizzly chassis where the LMG was and in the same postion on the

other side of the chassis. Place the FGCs with the front sight hooked

over the armor plating with the remainder of the pump pointing out.

Attaching the Very Heavy Auto Cannon

Begin by removing HAC from the Grizzly's right arm

with an X-Acto knife,if done carefully, this gun can be saved. There

are two small knobs on the outside of the Grizzly's arm which must be removed,

as this is where the VHAC attaches. Paint the arm in the camoflage

you will be using, except for the botton and a strip along each arm where

the support arms are glued on, as it is very difficult to so after the

gun is attached.

Attach the VHAC* from the Support Cobra. This

gun unfortunately cannot be removed w/o destroying the arm of the Cobra,

or losing the support mounts on the gun. I was fortunate enough to

have a friend who's Cobra became FUBAR and was allowed to destroy the arm

for the weapon. Any parts such as the hand gaurd or similar pieces

destroyed or lost in the process of removing the gun can be replaced rather

easily using some thin strips of balsa bent to shape.

Making the 'Mohawk'

Take a piece of scrap pewter or lead that is 8mm(l)

x 3mm(h) x 2mm(w) and cut out about a 4mm(l) x .5mm(h) chunk from

the bottom. then, starting on the other end, file away from the corner

to the notch at an angle so you end up with a .25mm lip, and a slight

angle coming form the other end (this allows for the mohawk to slope gently

along the top). Place on the head of the grizzly, with the lip pressed

against the rise in the grizzly's head, thin edge pointing forward, to

check for proper height. File as needed to make the back fit.

Place again on the head and bend the thin portion down until it touches

the sloped portion of the Grizzly head. File this portion of the

mohawk so that it is noticable thinner at the front of the bent portion

than at the back, but DO NOT bring it to a point. the section behind the

bend should remain squared. when this is done, slightly round all

corners and glue to the head.

Building the VibroAxe

Next hollow out the left hand, this can be accomplished

with a Dremel and small round engraving bit #106 or a small drill bit.

Cut a 1 1/4" length of the Pin. Take the hollowed sprue and carefully

cut into 1/8" and 3/16" lengths, being sure not to crush it. Slide

the 1/8" piece down the pin until the top of it rests 9/16" from the tip,

and glue in place. Take the axe handle at this stage and insert it

into the hollowed left hand of the Grizzly. Taking the 3/16" length

of sprue, slide it over the bottom of the pin, and up until a little less

than 1mm of the pin is showing. CAREFULLY glue this in place on the

pin making sure NOT to get any glue on the hand. DO NOT GLUE HANDLE

IN PLACE AT THIS POINT!!!

Use the hexbase and a larger cutting tip for the

Dremel to cut the shape of the axeblade. (Mine measures 19/32" tip

to tip on front, 716" tip to tip on back, and 5/8" from center to center

on blades when finished and assembled.) Sand or file this down to

a bit over 1/16" of an inch thick. Near the blade, begin tapering

the metal to a point to reseble a sharpened blade. Place the blade

against the pin for reference and decide how you like it positioned best

(fore and aft, as well as angle). When you find how you like it, cut the

axe blade in half at that location. Using a hammer, pound some lead

EXTREMELY thin, I flattened it to about 1/3mm. This will be used

as either two plain straps to hold the two halves of the blade together,

or can be shaped as is shown in the Panda's Tech drawing in the Vehicle

Record Sheet book for additional realism (I prefer the plain strap as the

lead becomes very weak at this thickness).

Using superglue, attach the two havles of the blade

to the pin where you like it (the center of my axe attaches at 9/32" from

the tip of the pin, aligning the lower point of the front blade with the

top of the smaller section of sprue). Take the flattened lead and

cut into strips wide enough to go from the top to the bottom of the middle

of the axe, and long enough to cross the pin, and still attach to the the

axe(mine measure 2mm x 6mm). Then take the two leaden straps attaching

them with superglue so they cross the joint, covering the pin and firmly

contacting the axe (be sure to glue the straps to the pin in addition to

the halves of the axe). Slide the axe so that the hand aligns in

the middle of the two pieces of sprue, and rotate handle till axe faces

outward. Glue the axe in place.

Take the 30mm strip of balsa and cut into a 10mm

and a 20mm strip. Put a small V-notch in one end of each strip to

place around the pin. In the 20mm stip, place a break in it at 5mm

from the notched end being sure to keep it attached to the rest of the

handle. Attach the notched end to the front of the handle directly

above the smaller Sprue piece, so that it contacts it, at a 45degree angle

down. Attach the notched end of the 10mm piece to the nub of pin

showing at the bottom of the handle under the larger sprue piece, pointing

out from the front and slightly down. Bend the remaining 15mm of

the long strip down so it touches the 10mm strip, it should leave approximately

a 3mm tounge at the end of the 10mm strip.

When attached, lightly cover the balsa with a coating

of THIN or SuperThin superglue. Taking a needle file or sandpaper,

smooth the balsa as there will almost certainly be stray fibers.

Coating with gloss black will make any imperfections in it VERY obvious

to assist in thier removal. Round the end of the tounge.

Building the HRP/24

Take the 1/16" steel rod (I used a .05" rod, which

comes out a bit thin, so i belive 1/6" SHOULD gain the proper girth) and

from it, cut 24 pieces of 15mm length for the rocket tubes. This

will leave you with a bit over an inch left, so if one is too short you

should have enough to replace it.

At this point you must decide if you wish to take

artistic license with the Rocket Pack, or build as it is seen on the King

Cobra. As the rule book says, many of the weapons come in different

designs from different manufacurers (for those of you that need rationalization

:). If you choose the Design from the King, with two rows of 12 tubes

apiece, you will need to build mounting brackets (which I chose not to

do, and as such you will be on your own). The design I chose allows

for both the HGM, and HRP/24 to be placed on the back w/o any mods to the

Mortar, and no excess work to be done on the HRP. An overhead view

is shown below, note that there are no gaps b/t the tubes, but the spaces

had to be implimented to show the staggering of the first 2 rows.

Also note that the last row of tubes lines up exacly with the row below

it, with an empty space on either end.

______TOP______

/ O O O O O O O \

/O O O O O O O O O\

\ O O O O O O O O /

\---------------/

BOTTOM

1 2 3 4 5 6 7

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8

The easiest way to accomplis this pack is to start

with a piece of lead flattened to about 1/16". Make a sheet that

will be a bit larger than the tubes when assembled. Lay one tube

down on the lead, and superglue it in place. Take the next and glue

it in place against the first tube. Do this until you have a row

of 8 rocket tubes assembled. To start the second row, place a tube

between tubes 1 and 2 on the bottom, and glue in place with a small bead

of glue near the middle, so the tops of the tubes dont appear as a solild

mass. Places tubes 3 through 8 in the same fashion in the middle

row. When those tubes are placed, glue tube 1 from the middle row

on, holding the HRP at an angle so the tube stays in the small groove created

between Bottom tube 1 and Middle tube 2, use the same process at the other

end to glue on tube 9. Next, being extremely careful, hold the Top

tube 1 in exact alignment over the Middle tube 2 and glue in place, again

using the glue in the middle. Proceed to attach, aligning in the

same way, tubes 2 through 7.

Cut the lead backing to end flush with the sides

of Bottom tubes 1 and 9, and the bottoms of all tubes. Then cut so

that the tubes stick up approximately 3mm from the top of the backing.

Now cut a strip of lead 16mm x 5mm and 1mm thick. This will act as

the band which surrounds the rocket pack, and should resemble the shape

shown in the above illustration. The strap will attach as shown in

the lower illustration. Hopefully that helps.

||||

|||||

| \||

| _|

|_/||

|||||

|||||

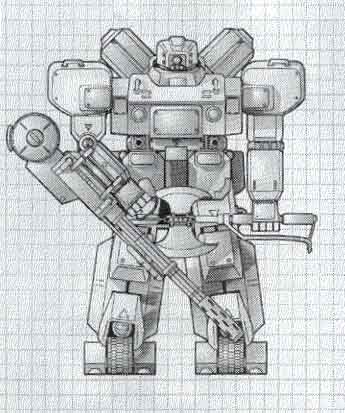

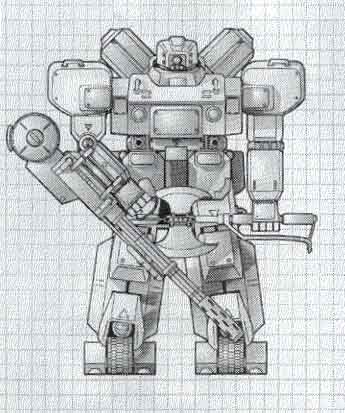

Finally, asseble and paint as normal. Below are pictures of my Finished Panda.

I dont have a Camera so I had to just lay them on the scanner. Any comments or questions can be sent to Nick Church.

* All the Crossbows i've purchased

come with a HGM, you may need to purchase a Grizzly (1206) instead, or

the Mortar Pack (1406), or as I've seen them packaged Heavy Weapons (1407)

** Said to be available in p/n 1407 "Heavy Weapons",

in my experience the Heavy Weapons blisters have been mortars

*** Anything that can be easily formed and will hold

it's shape can be substituted, I used lead as it is readily available to

me