M/T "Stolt Capability"

- the most Complex and Sophisticated

Chemical Parcel Tanker on the Oceans -

M/T "Stolt Capability"

- at anchor off Panama in 1999

-

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the most Complex and Sophisticated

Chemical Parcel Tanker on the Oceans -

M/T "Stolt Capability"

- at anchor off Panama in 1999

-

(Photography by Karsten Petersen ©)

With the introduction of this ship from the

nineties, we are suddenly in a completely different world compared to the

previous ships in my series of ships on which I have served during the

last 37 years.

The "Stolt Capability" was the 6th. ship

in a series of 7 "Innovation" class chemical parcel tankers delivered in

1998 from Denmark's "Danyard" in the city of Frederikshavn.

If we call the "Samoa" from the fifties for

the "simple ship",- and the "Jutlandia" from the seventies for the "super

ship", then it would be appropriate to call the "Stolt Capability" for

the "smart ship".

Suddenly nothing could be done manually anymore!

Everything is controlled by computers! And you cannot do anything wrong!

If you do, the computers tell you immediately, and block all further attempts

to go on, until the problem is solved.

Fun to compare the alarm points of "Samoa"

with those of "Stolt Capability"! Old "Samoa" from the fifties had

5 alarms,- while "Stolt Capability" from the late nineties has more than

3000! (Cannot remember the exact number!)

What makes this class of ship so totally different

from the previous ships, I have described, is most of all the propulsion

plant.

Instead of the usual arrangement which typically

could be a long stroke, slow speed diesel engine coupled directly to a

propeller, we now see the worlds first diesel-electric propulsion plant

in a chemical tanker!

The huge, traditional 2-stroke diesel engine

was now replaced by 4 medium speed motors each driving a high voltage alternator,

which in turn deliver power for a powerful 10.000 Kw. el- motor in the

bottom of the ship.

The layout of the engine room could therefore

be dramatically changed, so that it now appears with the various engine

room compartments placed on top of each other. This vertical design of

the engine room, makes it possible to squeeze all machinery into a remarkable

short engine room, leaving space for one more cargo section.

The diesel-electric power plant coupled with

a modern Becker rudder and a powerful electric bowtruster, makes the ship

extremely flexible and very manoeuvrable.

On the cargo side the ship is very well equipped

with 42 cargo tanks and 4 deck tanks, - altogether 46 tanks made from solid

stainless steel of a grade that is about 60% stronger than the traditionally

used 316 type -, and it can carry just as many different cargoes simultaneously,

since each tank has its own cargo pump and independent pipe systems.

It can carry virtually any chemical or oil

including those that require special attention, being it heating or cooling.

Heating can be done by steam, hot water or thermal oil,- or a combination

-, and cargoes requiring cooling are cooled by circulating a brine through

a special hydraulically driven cooling unit that can be easily removed

when not required.

Also the ship has its own N2 plant, that

can provide nitrogen blankets of very high purity for filling up the void

space above the cargo surface, so that sensitive cargoes are not contaminated

by exposure to atmospheric air, and at the same time the risk of explosion

of certain cargoes are also avoided, since the N2 blanket makes sure, that

the oxygen level is so low, that the risk of ignition is eliminated.

Of course there is a lot more, - especially

when it comes to automation and control, but it will be too much to mention

it all.

The ship from the early nineties,- the "Stolt

Markland" -, I described as a "happy ship". There are also "unhappy

ships", and unfortunately the "Stolt Capability" belonged to that category

due to leadership problems,- and surprising enough there was no desire

from the responsible people in the office to solve the problem.

Therefore I had to leave this nice ship although

I considered the ship itself near perfect. That statement, - of course

-, is only valid as long as things worked well. However, - when things

did not work as intended, it was more than a nightmare, when the computers

suddenly made themselves "independent" and did "strange" things, which

was not always easy to figure out. Also it was a little bit scary to work

with a voltage 15 times higher than on traditional ships.

But more about the disadvantages later.

For now please have a look at a fantastic,

near perfect ship - - -

M/T "Stolt Capability"

- the final touch, - being

fitted out at "Danyard", Frederikshavn, Denmark, just before delivery in

1998 -

(Photography by Karsten Petersen ©)

Builders: Danyard A/S, Frederikshavn,

Denmark

Length o. a.: 176,75 meters

Breath: 32,3 meters

Draught: 11,89 meters

DWT: 37042 t.

Propulsion: Diesel-electric

3 pcs. Wartsila medium speed, 9R32E

1 pc. Wartsila medium speed, 6R32E

Power: 10.000 Kw

Speed: 16,5 knots

Owners: Stolt-Nielsen Transportation Group

M/T "Stolt Capability"

Here a look at the "hotel"

section just before departure on the maiden voyage -

(Photography by Karsten Petersen ©)

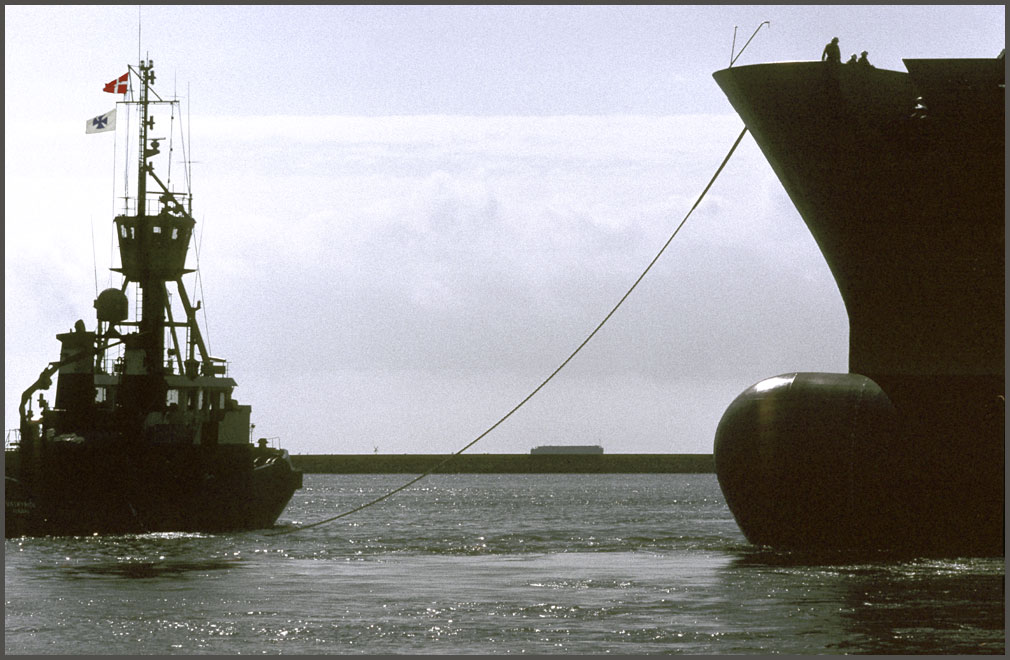

M/T "Stolt Capability"

Departure, - "Stolt Capability"

starts her maiden voyage guided by Switzer tug "Valkyrien".

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- propeller turning -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- on her way -

(Photography by Karsten Petersen ©)

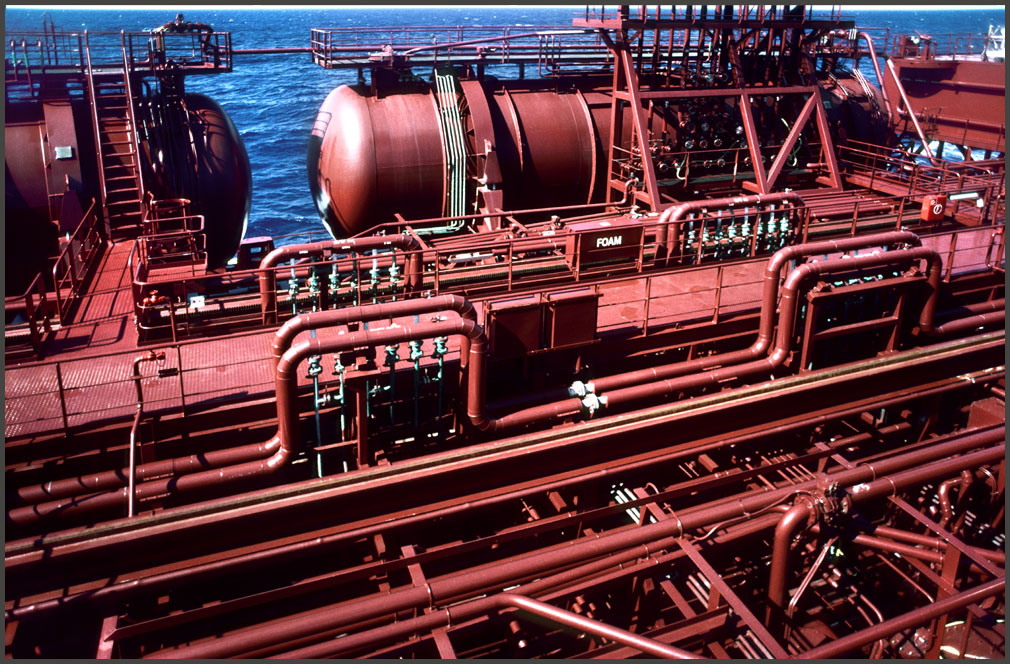

M/T "Stolt Capability"

- a look at the layout

of the deck equipment -

(Photography by Karsten Petersen ©)

It looks more like a complex industrial plant

than a ships deck, but all this equipment is necessary in order for the

ship to carry and handle virtually any type of cargo, as long as it can

be pumped!

M/T "Stolt Capability"

- a closer look at the

maze of pipes and equipment -.

(Photography by Karsten Petersen ©)

Here you can see some of the about 25 km.

stainless steel pipes on deck. Besides the cargo pipes, there are

also pipe systems for steam, fresh water, hot water, sea water, nitrogen,

thermal oil, fuel oil, brine, fire lines, vent lines, foam for fire extinguishing,

compressed air, hydraulic oil, - plus cables and pipes for sensors, feelers,

gauges and - - - - ???? I might have forgotten something - -

M/T "Stolt Capability"

- view to the bridge

-

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the joy of sailing

-

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- directly into the sunset

-

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- leaving a wake from

13.600 BHP behind, - and a fantastic sky -

(Photography by Karsten Petersen ©)

--------------------------------------------------------

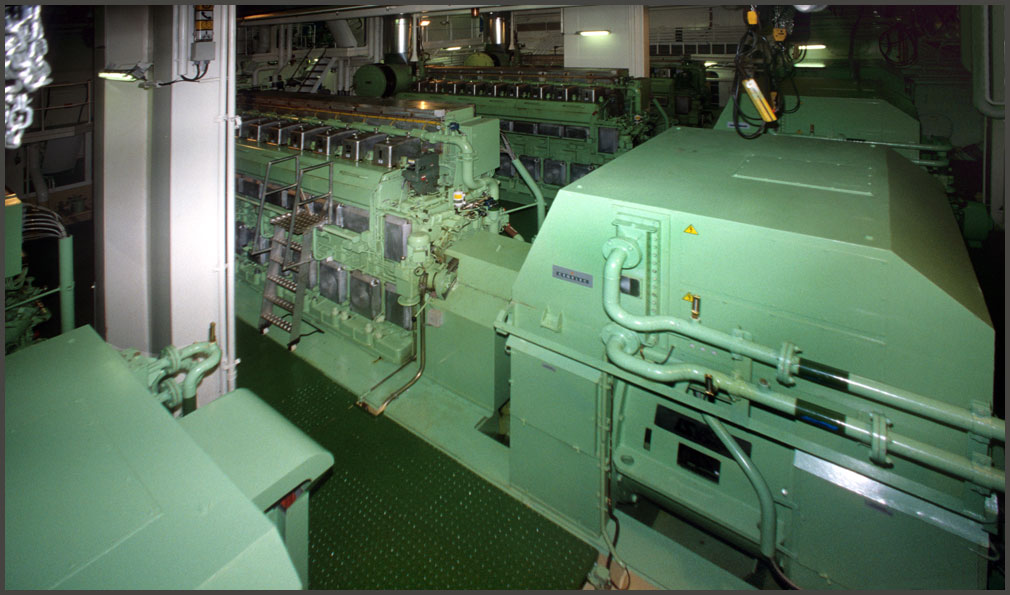

The engine room.

Being by far the most interesting thing about

this ship, - I have decided to include many pictures from the engine compartments.

Instead of one huge open engine room with

one big engine, - and all the auxiliary equipment placed on platforms around

it -, the engine compartment on the "Stolt Capability" is divided into

numerous small, closed compartments placed vertically on top of each other.

Yes, - Really! You can here talk about

a "vertical" engine room - - -

The biggest of these compartments is the

main generator room, where the 4 medium speed Wartsila diesels each drive

a high voltage alternator producing 6.600 volts.

Quite a change from normal 440 Volts ship

alternators.

M/T "Stolt Capability"

- The engine room with

four main engines and alternators -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- another view of the

main engine room -

(Photography by Karsten Petersen ©)

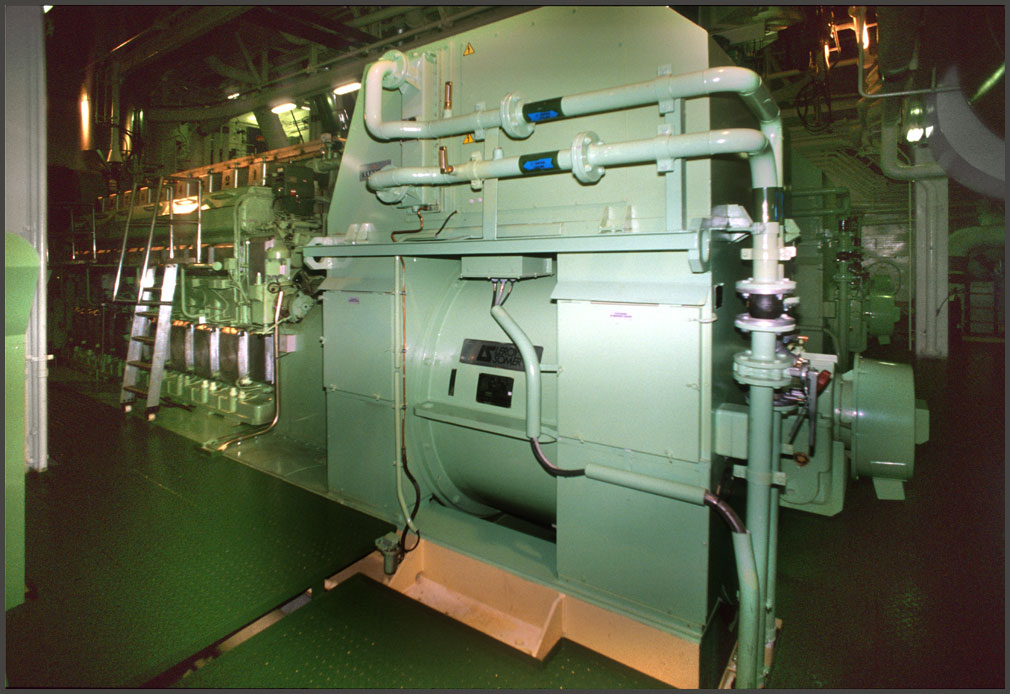

M/T "Stolt Capability"

- a closer look at a

6.600 volt alternator -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

Another view from

the main engine room showing two of the four diesel engines.

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- deep down below, -

the 10.000 Kw propulsion el-motor that drives the ship -

(Photography by Karsten Petersen ©)

The green square box on this picture shows

the 10.000 Kw el-motor that drives the ship. It is very small for so much

power,- it can easily fit into a normal kitchen -, and it is also interesting

to see that the gear,- the green "thing" in the foreground -, is

actually bigger than the motor itself!

From this gear box, the propeller shaft connects to the propeller.

Although the ships alternators produce 6.600

volts, the el-motor is supplied with "only" 1.500 volts.

The reason is, that on the way from alternator

to el-motor, the voltage is transformed down. Also it has to pass a synchro-converter,

that electronically cuts the original, steady frequency in bits and pieces,

and puts it together again to match the required rpm of the el-motor.

Actually the power transmission goes through

seven steps from generator to propeller. (Generator, alternator, transformer,

synchro-converter, el- motor, gear, propeller.)

This is a lot compared to the only two steps

in the traditional design where the power from the diesel engine goes straight

and directly to the propeller without any intermediate steps.

However, with the diesel-electric system

the control of the engine is very smooth! The propeller can actually run

at only 10 rpm if so desired, and the process of going from ahead to astern

is very smooth and completely step less without having to stop and reverse

the engines, and then starting up again in the opposite direction like

it is done with the traditional design.

It sounds like perfect,- and from an engineers

point of view it is. (Or at least near perfect as mentioned before!)

But there are drawbacks, - especially for

he who has to pay the bills!

As mentioned above, - the diesel-electric

design requires 7 steps from generator to propeller, and each step means

a loss!

The traditional design have two steps,- engine

to propeller-, and consequently the losses are much smaller.

A diesel-electric ship like the "Stolt Capability"

will typically burn more than 60 tons fuel a day, - all included -, while

a traditional design of same power will typically burn less than 40 tons

for propulsion, while the auxiliary engines will typically burn 5 - 6 tons

extra for the remaining consumption.

In addition I am quite sure, that the very

complex diesel-electric design costs considerably more in maintenance than

the much more simple, traditional design.

If you get a short circuit in a normal 440

volts switchboard, you will get a black-out and a possible damage to a

bus bar or to some switch, but you will be able to fix it, and the ship

will continue.

If the same thing happens to a 6.600 volts

switchboard, the whole section melts down completely,- there is nothing

left-, and you cannot fix it!

M/T "Stolt Capability"

The propulsion el-motor

behind, - and the reduction gear in front.

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the compartment with

sea cooling water pumps and central coolers -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the compartment with

sea cooling water pumps and central coolers -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- and here the compartment

with the hydraulic power packs -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the separator room

-

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- another view of the

separator room -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the compartment with

refrigeration machinery -

(Photography by Karsten Petersen ©)

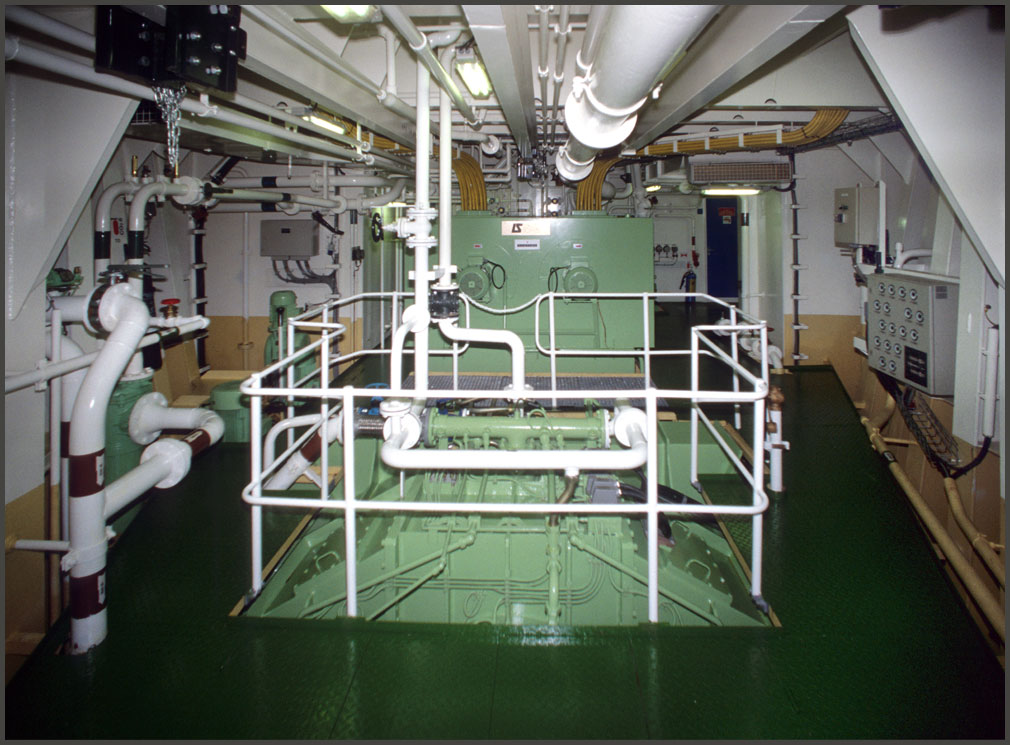

M/T "Stolt Capability"

- the "converter room",

- the compartment with the high voltage switch board -

(Photography by Karsten Petersen ©)

In this compartment the frequency from the

alternators are chopped into bits and pieces, - and then put together again

in accordance to the desired revolutions of the propeller.

The blue door in the background leads into

one of the transformer rooms where the voltage is reduced from 6.600 Volts

to "only" 1.500 volts.

M/T "Stolt Capability"

- here entering the engine

control room -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- the main engine control

console -

(Photography by Karsten Petersen ©)

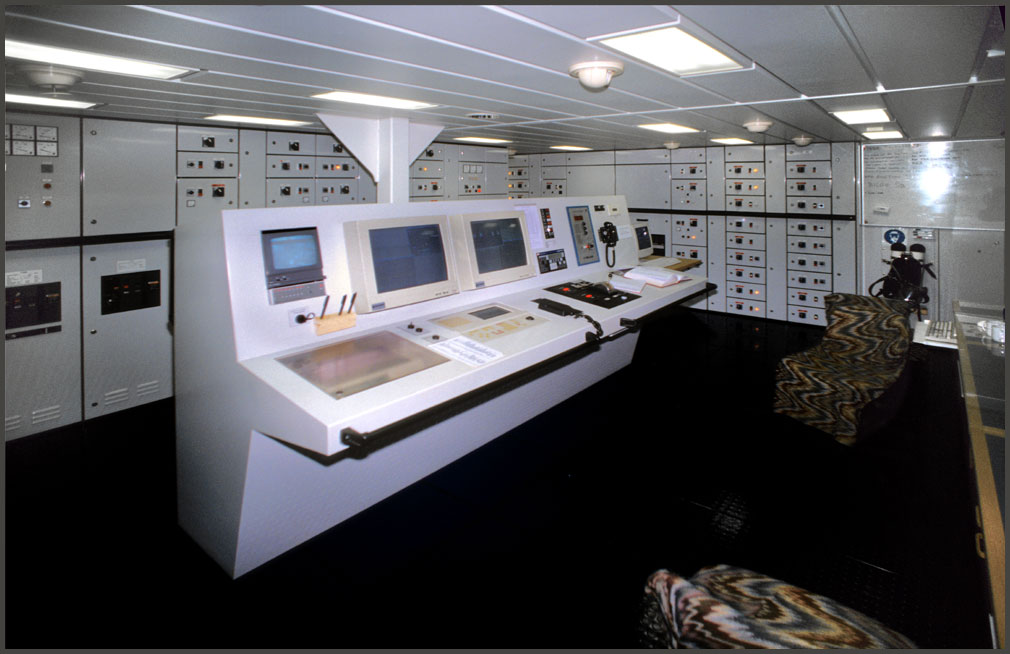

The engine control room.

M/T "Stolt Capability"

- another view into the

impressive engine control room -

(Photography by Karsten Petersen ©)

M/T "Stolt Capability"

- a final look the main

engine control console -

(Photography by Karsten Petersen ©)

This quite small and not so impressing looking

desk in the middle of the control room is actually the very brain- and

nerve center of the whole ship.

From here everything is powered, started,

stopped, controlled and constantly monitored, - and without it the ship

would be just a "dead", cold and useless steel construction!

Interesting to think about!

Back to "My Ships"

Back to "The Ships"

Updated: May 14. 2005,

- Nov.09.2008, - Nov.11.2008