An Intense Look at Flow Intensification

By Mike Bujold

For the last year and a half, it has been my distinct pleasure to be a member of the Edmonton hydraulics team. I am privy to almost 50 years of combined experience, and I never miss the chance to pick Tim, Jim or Tom's brain. I must say without a doubt that we get some of the most, shall we say, interesting customers with interesting ideas through our door. One thing I am constantly reminded of is the importance of imparting our knowledge and experience to the customer. It is our job to inform them as best we can as to the particulars and especially the dangers of hydraulic systems.

I recall one occasion where a customer was debating the conductor size on the 31 ton Logsplitter with Tim. The customer believed that a larger return hose (3/4"ť) was unnecessary. His reasoning was that since there was 16 GPM going into the cylinder, there could never be more than 16 GPM coming out. Obviously, this customer was unaware of some crucial information regarding flow. More specifically, what happens during extension and retraction,

It is important to understand all the principles at work in a hydraulic system. In this customer's case, his lack of knowledge would cause nothing more than embarrassment when talking to someone who was more experienced, but ignorance of these facts when designing and implementing a hydraulic system could lead to injury or death if the designer or operator is not aware of them.

The principle at work here is flow intensification. Flow intensification in a cylinder will always occur during the retraction stroke. This is because of the smaller piston area on the rod side, called the annulus area. The fluid will flow into the rod end at a specific rate, and hence, the piston will move at a specific velocity proportional to the flow. If the flow on the rod end is constant, and we know the annulus area is constant, velocity will be constant. If we look at the base end of the cylinder, we know the piston is travelling with a specific velocity. Since velocity stays the same, but our base end area is larger, flow on the base end must therefore be proportionally higher to keep our velocity the same, since velocity cannot change. This is the basis behind the oft-overlooked flow intensification.

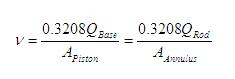

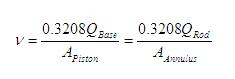

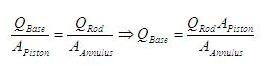

Let's look at our Logsplitter example. There are 3 things to consider when looking at flow intensification: first, the area of the piston, second, the annulus area, or the piston area minus the rod area, and the rod end input flow. To determine our intensified flow, we will need to rearrange the equation for cylinder velocity. To do this, we will jump into some basic algebra most of us remember from level 1 hydraulics:

By combining these equations we get a simple formula for flow intensification, or the flow coming from the base end of the cylinder:

(The constant 0.3208 cancels out on both sides of the equation.)

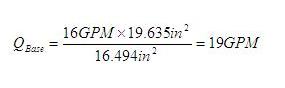

So, using our 31 ton Logsplitter example (5" bore, 2"ť rod), our piston area works out to 19.635 sq. in. and our annulus area works out to 16.494 sq. in. We will use a flow of 16 GPM:

At 19 GPM, according to the chart on page 459 of the Mobile Hydraulics Manual, our conductor size should be in the area of 3/4 inch! For 16 GPM, we might have been able to get away with 5/8 inch hose, but as we've determined, the maximum flow we will see will be more than that. Note that on the extension stroke, our flow out of the cylinder will actually be less than what is being put in the base end, about 13 GPM.

Hydraulics is a very elegant branch of mechanics, and has a variety of uses in a variety of ways. Used improperly, or without understanding them fully can be dangerous. Being aware of the various nuances of hydraulics can be a valuable asset when explaining concepts to customers, to make them aware of not only the dangers, but also the interesting and creative ways hydraulics can be utilized.