|

|

|

|

|

|

|

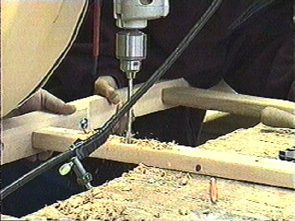

Above: Stantions are tight enough to require pounding in. Step #8: Bolt the false runner onto the runner using smooth or rounded top bolts and countersink into the bottom of the runner giving yourself enough room to slide a washer in before putting the nut on (I used nylon insert nuts). Cut the bolts off flush with the bottom of the runners. Note: I found it better to drill a very small hole (like 1/16") first, then use the large bit to make the countersink for the nut, and then drill the hole to 3/8" for the bolt. Next is drilling holes for the stantions. Center the holes at the locations marked for the stnations and drill one inch holes. |

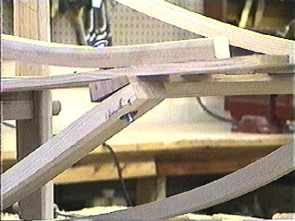

Above: Stantions installed, bottoms sticking through and tops to be measured and cut off later. Step #9: If everything goes right the stantions should fit very tightly into the one inch holes. I had to pound them in with a wooden mallet. The bottoms of the rectangular part of the stantions should be flush against the runners/false runners and the rounded ends will be sticking down below the runners. If the stantions are a little loose (they were on my first sled) they will still work ok, but the goal is a snug fit.

|

|

|

|

|

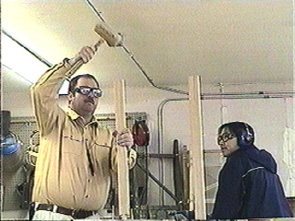

Above: Drilling one inch holes for the cross pieces. Step # 10: Measure from the bottom of the runner up each stantion seven inches and mark the distance at the center of the stantion width for each of the six stantions. Drill a one inch hole at that mark in each stantion. Warning: be sure that you measure from the bottom of the runner for each one. I made a mistake on mine by not paying attention and wound up with the front cross piece being 1" lower than the others which I remedied by adding another cross piece to the top of the front cross piece to fill in the space. This might be noticable in some of the photos. It was a screw up.

Note: When I say left, I mean the left side of the sled when standing behind the sled looking at it from the rear to front.

|

Above: Stantions and cross pieces in place. Step # 11: The next couple of steps are very important as they determine the alignment of all of the parts. First, set the runners side by side so that they measure exactly 21 inches apart from outside to outside at the very back. Keeping that at 21 inches space them so that they measure exactly 20 1/2 inches apart at the front measuring, likewise, to the outside edges. This gives you a 1/2 inch "toe-in" to make the sled track streight. I have been told that a 3/4" toe-in might be better, but I do not remember who told me. Probably, the longer the sled the more toe-in it needs? Now, with the runners precisely placed, measure the space between each pair of stantions where the cross pieces will go. I recomend measuring this just above the runner/false runner. After measuring the front pair then mark a cross piece so that after the ends are rounded off and poked through the stantions they will stay exactly that far apart. Repeat for the middle stantions and then for the rear stantions. Make two identical cross pieces for the rear stantions. The other one will be placed at the top of the rear stantions later. |

|

Step # 12: The next step is difficult to explain so do not be afraid to look through the photos to see what I am talking about. I do not have a good photo of this step. Sorry. After the three cross pieces have been tightly fit into their holes then lay one of the slats for the bed of the sled on the cross pieces. Line it up on the left side with the stantions as streight as possible for the best looking fit. The front and back should hang over a little and will be cut off later. Mark the slat for each side of each stantion with your sharp pencil. Use a small square to draw the six lines all the way across the top of the slat. Now slide the slat to the right side and see if all the marks line up with the stantions on that side. If they do then great work! Mine did not. So I made new marks for the stantions on the right side and then averaged them by drawing new lines across half way between each one and erasing the first lines that I had drawn across the slats. This should be easyer to understand when you are doing it. Anyway, get another slat and line them up together and copy the marks from the first one in exactly the same places on the second one. These are what will keep all the parts lined up. Need a box of 3/4" #10 wood screws.

|

Step #13: Cut one inch deep notches in each slat at all the places marked for the stantions. Three on the left side of the left slat and three on the right side of the right slat. Now place the slats back on the cross pieces and slide the left one over so that the stantions fit into the notches and the left side of the left stantions are flush with the left side of the left slat. Do the same thing for the right side. If the runners are still lined up then all of the stantions should now be lined up. Srew these two slats down to the three crosspieces with 1/2 to 3/4 inch size 10 wood screws (short enough so they will not go all the way through). Drill pilot holes and countersink so that they will be flush and neat. Step #14: It would be nice to have some helping hands with this step. Hold one of the rails against the inside side of the right stantions with the bent end resting on the slat which is resting on the front of the runner. Move it forward and back to get the best looking fit with the rail about 3 feet up from the top of the false runner at the back of the rear stantion. When it looks just right then hold it in place and using a sharp pencil mark a line across each of the three right stantions under the rail. The rail will be attached to the tops of the stantions. Using a measuring tape and measuring twice to avoid mistakes mark the stantions on the left side so that they are exactly the same. Now cut all the stantions along the marks. |

|

|

|

|

Above: Lining up the parts in the front. In these photos you can see where I messed up the second cross piece. Step #15: Drill pilot holes and countersink 1 1/2" #10 wood screws through the rails and down into the tops of the stantions to secure them in place. Place the front cross piece between the runners and the slats so that the thick edge is toward the rear and the corners line up exactly with the corners of the front of the runners. Note that the outside edges of the slats and the rails are lined up with the stantions and not with the outside edges of the runners. So you should have the edge of the slat and rail set in about a half inch from the edge of the cross piece and runner. When everything is clamped or otherwise held in place drill a hole through the rail, slat, cross piece, and runner. Bolt them together with a 3/8" bolt. Don't forget to countersink the bottom so that the bolt can be cut off flush. |

Above: Here I had too little bend in the runners leaving a small gap between the rail and the slat that should not be there. Step #16: At about this time you should take the handle bar pieces off their bender. Choose enough of the best ones so that they will be close to a half inch thick when glued together. Sand them good and smooth, put wood glue on, and clamp them for a couple of days. Do not worry about cutting the ends to the right length yet (do it later). Step #17: Lay the rest of the slats across the cross pieces. Line them up and space them so they look good. Screw them all down to the cross pieces (including the front cross piece). Note that they will look best if the screw holes do not go all the way through the cross pieces and they are all lined up and countersunk to be perfectly flush with the top of the slats. |

|

|

|

|

Step #18: Cut slats and rails flush with the front cross piece in front and cut slats and rails flush with the back of the rear stantions in back. Drill 1" holes and install the upper cross piece on the rear stantions. Look at the photo above right, it should be a couple of inches below the rail. Need 14 eye-bolts at least 3 inches long with washers/nuts. Install one pair of eye-bolts for each stantion. I placed them two and a half inches from the front and rear of each stantion. These need to be very tight and countersink the bottoms so that they can be cut off flush later (see photo below on right). Add one more pair of eyebolts to the rear stantions about one to two inches below the upper cross piece. Drill the hole through the width of the stantions after carefully measuring so that the round part protrudes to the rear in a vertical possition. Bungi cords will be connected from these to the brake(s) to hold them in the up position. No need to counter sink, but cut off the excess threads after tightening. |

In the above two photos you can see it starting to come together, notice the ends of the stantions and cross pieces are still sticking out. Step #19: Find a good drill bit between 3/8" and 1/2" to use for the peg holes. Check to be sure the sled parts are all aligned as close as possible and stantions and cross pieces are fully inserted. Use the bit to drill holes through the width of the runner so that it goes through the center of the rounded portion of the front stantion on both sides. Do the same for the rest of the stantions, but drill the hole in the false runner. Drill holes through the width of each stantion so that the holes pass through the center of each cross piece. Don't forget to do the same for the upper cross piece on the rear stantions also. Using a small (5 or 6 inches) piece of your wood (scraps if available) round off about 3 inches so that it will fit into one of the holes, but too tightly to be pushed in by hand. Use a wooden mallet to drive it into the hole until 1/4 to 1/2 inch is sticking out the other side. Cut it off flush on each side. Repeat this procedure for all of the holes that you have drilled. |

|

|

|

|

|

|

|