|

|

|

|

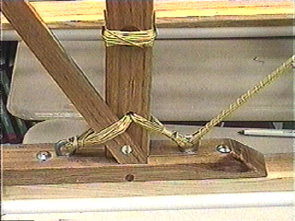

The above photo shows the eye bolts in place and the lower part of the handle bar brace with a 1/4" stove bolt through the middle stantion. Step #20: Need six 1/4" stove bolts 2 to 3" long w/ nuts & washers. Need to cut the two handle bar braces; The width should be equal to or slightly more than the handle bar. The thickness should equal the distance from the outside of the middle stantion to the outside edge of the runner or slightly less (about 3/8"). The length should extend from the runner at the middle stantion to two inches past the top of the rear stantion. Hold the brace so the leading edge of the lower end is aligned with the leading edge of the bottom of the middle stantion on top of the false runner and the lower edge of the upper end is lined up with the top rear corner of the rear stantion. Be sure that in this position there is room to put a 1/4" bolt through the rear stantion and brace. If not then adjust the position as necessary. When the position is right mark the lower end so that the proper angle can be cut. Cut the angle and then reposition the brace and drill a 1/4" hole through it and the middle stantion and then bolt it in place with a 1/4" bolt. Cut off excess threads. The threads should always go toward the inside. Repeat this procedure for the brace on the other side. |

Above: Cutting the threads and the excess from the bottom of the stantions to make everything flush with the bottom of the runners. Step #21: Before installing the handle bar measure the ends from the bend and cut them so that they will be equal or very close to equal in length. Do not cut them too short. To check; hold the handle bar in place by clamping it onto the rear stantion so that the ends are lined up directly over the braces. Measure the distance on each side from the top of the false runner to the bottom of the handle bar streight up. This distance should be 36" (more or less as you desire). Now the handle bar ends should extend along the brace for about six inches below the rear stantion (see photo below on the left). If it is too long then mark each side equally and remove the clamps and cut the handle bar ends at the marks. Reposition the handle bar and clamp it in place leaving space to drill holes through the rear stantion, brace, and handle bar on each side. Drill a 1/4" hole in each and then bolt them together with 1/4" bolts. Drill a second hole on each side through the handle bar and the brace about one inch from the lower end of the handle bar and bolt these also. Cut off excess threads after making sure all the bolts are tight. Give the whole sled a couple of good coats of oil or other water proofing. Next is wrapping. |

|

|

|

|

|

|

|

|

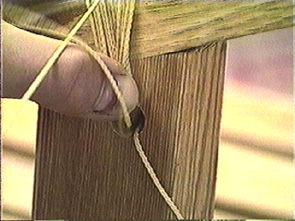

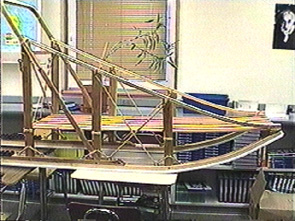

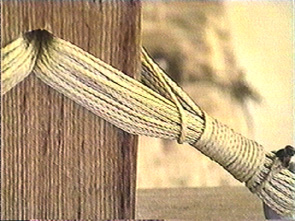

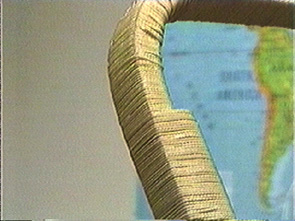

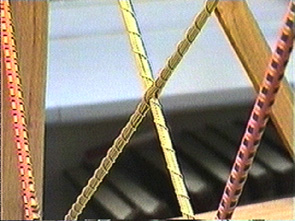

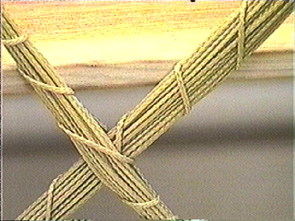

Step #22: Need good quality size 12 or a little larger braided nylon twine. I cannot explain how to do the wrapping. I figured it out myself by looking at other sleds. So I have provided here many photos for you to look at and figure it out yourself. I have been told, and I believe it is true, that strips of wet rawhide make the best wrapping. I have also been told or maybe I read that the nylon twine will break down and need to be replaced after every one or two seasons. We'll see. When drilling the holes to wrap down the rails be careful not to drill into the wood screws that you put in earlier. I wrapped the handle bar twice and then coated the sides with epoxy (the kind used for boats) to keep it tight, but I did not put epoxy on the part that I hold because I was worried about it getting slippery. |

|

|

|

|

|

|

|

|

|

|

|

|

|

All this wrapping is going to take a lot of time and may result in sore fingers. I would get some pretty raw spots and my students whined so much that I did almost all the wrapping myself. Every part that looks like it should be wrapped should be wrapped including each stantion and cross piece. I used the same drill bit to make the wrapping holes that I used for making the wooden peg holes. Again, be careful not to drill into the screws at the top of the stantions and in the cross pieces just behind each stantion. Look at the next page where I have the instructions for finishing up the sled and more photos. |

|

|

|

|

|