STM Mechanical

Design

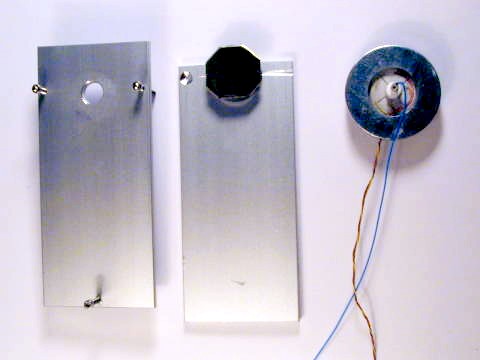

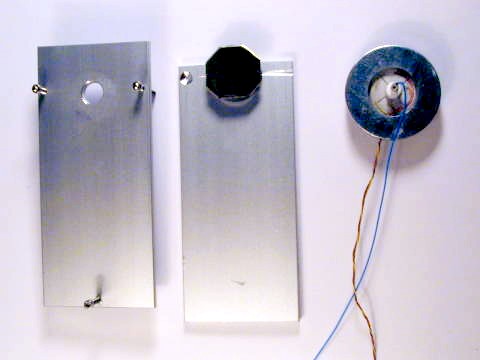

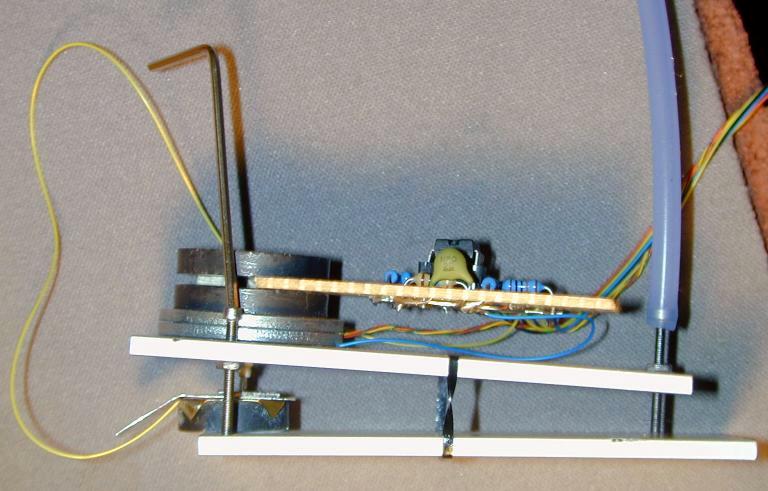

The disk scanner assembly is covered in detail, in subsequent pages. The remaining parts of the mechanical design are basically a sample stage, a scanner holder, and three screws that form the approach mechanism. The approach mechanism is basically a lever (sample stage) moved by three fine pitch screws. I cut two pieces of flat aluminum stock 1/8”x 1-½” by about 3-3/8”. One to hold the disk scanner and screws, the other to hold the sample.

Scanner Holder

PDF image(inch) PDF

image(mm)

For the Scanner holder I

drilled Four holes in the aluminum stock piece (see diagram) . One hole

large enough for the scanner post to pass through with plenty of clearance

and three clearance holes for the UNCF #1-72 screws, see diagram. (Originally

I drilled and tapped the holes but the threads in this thin soft aluminum

did on hold the screw securely.) I super glued two 1-72 nuts on each hole,

one on each side. To insure the thread was aligned I put a screw through

the hole first and very lightly tightened the nuts on the screw before gluing

the nuts to the aluminum piece. If you over tighten the nuts you will not

be able to turn the screw when you’re done, and be careful to keep the glue

off the thread of the screw.

Sample Stage

PDF image(inch) PDF

image(mm)

The other aluminum stock

piece is for the sample stage. I first marked the location of where the

three screws from the scanner mount touched the when the two pieces are

lined up with the screws extended. I made a ~ kinematic mount by using the

point of a large drill to make shallow a conic hole on one landing point

(see diagram) , and used a small file to make a “V” groove through another.

The screw landing point far from the tip should be a flat surface.

For this design I used a ceramic magnet disk to hold a removable sample

stub (steel disk or steel washer that the sample is glued onto with conductive

epoxy or paint) Ceramic magnets are usually fairly good insulators. To make

electrical contact to the sample stub I glued a very thin piece of brass

shim stock on top of the disk magnet and soldered a wire to the brass shim.

This wire was connected to the sample bias voltage. I glued the disc scanner

and sample holder onto their respective aluminum mountings (see diagram).

Mounting for the pre-amplifier

As a temporary mounting for the pre amplifier I placed a magnetic disk

on the back of the disc scanner, placed one edge of the pre amplifier circuit

board on top and set another disk magnet on top of the first. With the edge

of the pre-amp in between the magnets, this holds it like a clamp and the

pre-amp can still be removed easily. If you want to drill mounting holes

and put in standoffs and bolts that would be more professional.

Home Simple STM Project Home Project Overview Progress

Mechanical Design

Disk Scanner Description How to Make a Disk Scanner Mechanical Approach

Mechanism

Mechanical Bill of Materials Electronics Design Electronics Schematics

Electronics Bill of Materials Operating the STM Images