What

wattage of soldering iron should I have?

I would recommend at least a 60 watt iron. One with a flat tip is

especially useful for building batteries and soldering wires that are 12 to 14

gauge. Anytime you heat up electronics or a battery for to long of a time are

taking the risk of damaging it. Having a better wattage iron melts the solder

quicker.

What kind of solder should I use?

I recommend using a rosin core solder. Using an acid core solder will

destroy components. I use a 60/40 rosin core solder. This solder will melt at

about 371 degrees. If you need a solder the that will melt at a lower

temperature try a 63 / 37 solder. I use a .031 inch thick solder. It is good

for small stuff and building batteries.

What

is the best way to build a battery?

I recommend using sandpaper or a emery board to rough up the tops of the

battery. This will help the solder stick to the top of the battery. Remember

do not get the battery to hot while soldering them together. Heat kills them

and you can ruin them before you even use them.

Tin

How do I

know when my soldering iron is ready?

The solder should melt very easy and flow like a thick liquid, if it doesn't

then the iron isn't ready.

How do I

soldering capacitors to my motor?

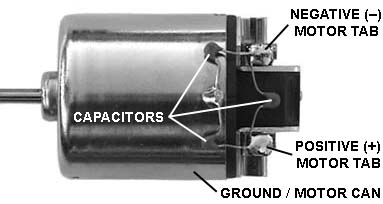

First make sure that you motor requires them. May new motor have internal

capacitors built in. If you motor requires three capacitors make sure the can

is clean. Decide where they are going to mount on the can and use sandpaper to

rough up that area. Note some motors only require two capacitors. If this is

the case many motors such as the Reedy MVP come with a capacitor mounting post

called a solder tab. Here is an example of a three capacitors motor.

Solder a

0.1µF (50V) capacitor between each of the following:

- POSITIVE (+) motor tab &

NEGATIVE (-) motor tab.

- POSITIVE (+) motor tab &

GROUND tab

- NEGATIVE (-) motor tab &

GROUND tab

Things to keep in mind.

Clean and tin the soldering iron

tip often.

Always tin the parts of the wire

that are to be joined.

Whenever possible, twist the

wires together before soldering for a good mechanical connection.

Do not over tin the wires or

apply too much solder to the connection.

Always insulate your soldered

connections to prevent shorting.

Do not over-heat what you are

soldering

***Remember that solder does

contain Lead which should in no way be swallowed. So make sure you wash your

hands and don't intentionally breath in the fumes. |