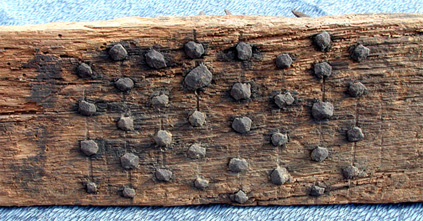

Back Side of Primitive Flax Comb

Clues in the back side of this flax comb reveal its construction. To begin with, the maker used an awl to scribe lines across a board into which the nails will be driven. The comb shows alternate rows of four and five nails staggered for most effectiveness as a comb.

The maker, was probably an amateur blacksmith. This is evident in the construction of the square nails in its construction. (Blacksmiths who often make hundreds or thousands of nails develop a routine of forming not only nails of consistent length and shape. Additionally, they will develop a habit of forming the nail head with exactly the same number and angle of swings of their mallet in forming each head.) The comb above shows quite a variation in nail heads.

Without knowing the conditions under which the comb was created, the person who made it should be given a lot of credit as the nails could have been formed from pieces of old recycled iron such as horseshoes or worn wagon wheel rims.

Knowing nail heads will be exposed, some smiths go to extremes to make them look nice and often decorative. Examples of these are presented farther down on this page.

Below is a comb whose tines are made from round stock. The wooden box was used to protect the tines from becoming bent or broken (not to mention puncturing human parts that got too close). Some boxes will contain a handful of flax tow which prevents rust from forming on the tines.