|

|

Fuzzy

logic controllers

Wide range of opportunities is

opened in the field of digitally controlled systems by

microcomputer development. Digitally measured informations are

rapidly processed. Complex systems are easily controlled.

The diversity of controlling software allows more creativity to

experts. New approach in controlling was introduced, using the

fuzzy regulators. The expert, familiar with the certain process,

easily can implement the solution, by simply writing and

changing the program code.

Before the microcomputers appeared, the automatic process

control and machine control was based on analog regulators.

Digital control algorithms are slower then the analog ones.

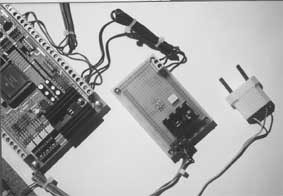

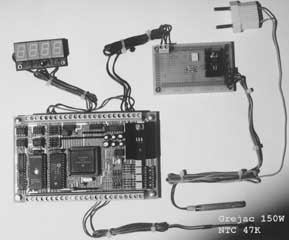

Experiment system detail

Flexibility in control realization and modifications are easy

using software, simply changing the code. New methods of control

are introduced. In many different conditions, these prove to be

very efficient. A specific application: neural networks and

fuzzy logic use on system control.

Digital

Controlling

Digital

control offers opportunities for new modalities, that analog

regulators were not able to offer (or are difficult to

implement): data acquisition, system identification, adaptive

control etc. (terms known from the theory of digital

controlling). Two important terms are connected with digital

systems: discretisation by time (sampling time) and quantisation

by level. The sample rate defines successive moments in which

sampling of continual values is being performed. As a result of

AD conversion, quatisation of continual values appear.

Intelligent control application can be understood on the need of

performing a regulation of a physical dimension in next

circumstances:

1. On real systems, different disturbances influence

constantly

2. Real processes, in most of the cases are nonlinear

3. The processes are changeable

The outlined demands often are met in daily life. Intelligent

controlling is thus necessary.

FLC Designing phases

Fuzzy Logic Controllers (FLC) are an example of such kind of

controlling. Convenient for the systems that are hardly modeled.

These are the phases of designing the Fuzzy regulators:

1. Process analysis

2. Rule determination, by an expert

3. Simulation of the Fuzzy regulator. If we do not receive

the desired results, we have to repeat the steps.

The realization of FLC in a digital control system consists

in source code writing (we used the C language in our example).

Based on given temperature, the regulator reaches the desired

value and maintains it, until a demand for another value

appears, given by the user. Before starting to write the program

code, analysis (and surveillance) on the specific control system

is necessary It is desirable to describe the system

mathematically, to simulate the process using a microcontroller

and then to implement the program. The purpose of the simulation

is: using mathematical algorithms we try to describe the

happenings in a real system. This way we can verify if the

control algorithm fulfills the demands in reality. Usually,

initial conditions are given, in time domain. The advantages of

such systems are to insure stability, precision and speed.

Fuzzy Logic

In the classical theory of

groups, we say that a certain element belongs or does not belong

to the appropriate group.

Picture 1. Belonging function

The experiment -

water temperature regulation. The water can be hot or cold. Such

approach is simplification of real situation. In this example,

the graduations of temperature are neglected. This approach is

thus unprecise. In everyday life, we can hear terms like, little

bit colder, little bit warmer, cold, hot, very hot, etc. One

solution is to introduce terms like in the picture 1, : Very

Negative, Little Negative, Around Zero, Little Positive, and

Very Positive (VN, LN, AZ, LP, VP). The fuzzy logic theory was

introduced for this kind of representation. Lotfi Zadeh was its

inventor. A value can belong to different representations, this

way its description becomes uncertain, fuzzy. For instance, the

fuzzy value F=3.5 is LP with belonging degree n=0.25 and VP with

n=0.75.

Expert Systems

Fuzzy logic usually is associated with expert systems. In

these, the actions perform in real life by experts, can be used

for programming computer systems that later can imitate or

perform the job of experts. Manual control involves man's

intelligent action of monitoring and controlling the

certain process. With this approach, we can accomplish good

control, because the expert knows how to guide the system. In

order to write a program for FLC, it is necessary to introduce a

group of fuzzy rules. The rules describe the expert's action.

The situation in the control system can be described as next:

the expert monitors the system (example: the deviation of

temperature value from the given, initial, temperature) and

decides how much to warm up the water.

Fuzzy rules

In expert systems, the knowledge of the expert is described

the next way: IF the mistake has this value THEN heat for that

value long time. In most of the programming languages, it can be

implemented with IF THEN rule. The next situation shows an

example of control: water is heated. At the start it has the

room temperature, lets say about 22 C degrees centigrade and has

to be heated to 40 C. An "average" expert will

probably react the next way: lets heat the water until it

reaches the 40 C, then, we will maintain the temperature to

40 C, on the principle of work of an ON/OFF regulator. Instead

of using a classical ON/OFF, we often use the ON/OFF

regulator with hysteresis. This means the temperature is

maintained in certain intervals, for instance between 39 C and

41 C. The question of quality of this way of control depends on

the demands of the buyer, that orders the system (temperature

regulator). First, it is useful to notice that the temperature

is oscillating between 39 and 41 C. The second, if in the system

exists a noticeable delay (the energy of the heater is not

instantly transferred) it is logical to expect that in

temperature reaching, there will be an overstepping of the value

of 41 C (the higher delay, the higher temperature) and the

interval (39, 41 C) is expanding.

Picture 2. Control system structure

In case of ON/OFF

regulator, in fuzzy logic, the temperature regulation will be

implemented the next way :

IF temperature < 39 C THEN heater ON

IF temperature > 41 C THEN heater OFF

This regulator can be easily implemented both in software or

hardware environment (digital or analog control respectively)

and it is pretty simple. We have to be aware that there also

exist groups of rules that describe the temperature regulation

more precisely, in this system.

Picture 3. Error and error change

Bart Kosko showed

theoretically that the Boolean algebra (1 or 0) is only a

special case of fuzzy logic, actually its subgroup. The ON/OFF

regulator is only a special case of FLC. FLC should be

considered as an algorithm that based on two values (error and

error change) calculates the control. It means how much (inside

a period T=4 seconds) to heat, to achieve the desired

temperature (Picture 5).

Picture 4. Fuzzy logic controller

structure

The error (given

value - instant value) gives the information how much the

instant temperature is away from the given one. The error change

(instant error - previous error) gives the information about the

speed of achieving the given value (Picture 3). These two values

are the input in FLC and they have specific values (in C).

Achieving the real value of control

The data processing of the achieved information is performed

in next 3 phases:

1 . Scaling

2 . Look-up table (calculating the fuzzy control)

3 . Inverse scaling

Picture 5. PWM signal

Scaling: The error

and the error change are scaled. For instance, if the given

value is 40 C, and the instant value is 30 C then the error is

e=10 C. If the previous error value was 28 C, then de=2 C. These

values are sampled in k*T moments and k is an integer. The

error and error change are recalculated into fuzzy variables

ef and def. The fuzzy values are supposed to be in the interval

between -4 and 4. To these values an interval of real numbers is

attached (e and de). On the basis of given value and starting

(initial) temperature value, we determine the emin and emax. For

instance, if the given temperature value is 40C and starting

(initial) value is 10 C, we calculate the emin = - 30C and emax

= 30C. We presume that during 4 sec, the temperature can

maximally rise for 1 C; it comes out that demin = - 1 C and

demax = 1 C.

LOOK UP TABLE:

(calculating the fuzzy control). When we want to determine the

ef and def, on the basis of the Look_up table we determine the

uf (fuzzy control).

| ef\def |

-4 |

-3 |

-2 |

-1 |

0 |

1 |

2 |

3 |

4 |

| -4 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| -3 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| -2 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| -1 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| 0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

| 1 |

1 |

1 |

1 |

2 |

2 |

2 |

0 |

0 |

0 |

| 2 |

2 |

2 |

2 |

3 |

4 |

4 |

3 |

2 |

2 |

| 3 |

3 |

3 |

3 |

3 |

4 |

4 |

4 |

4 |

4 |

| 4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

Look-up table

Picture 6. 3D projection

of Look-up table

Descaling: Control in real time, demands the translation of

fuzzy control into real value. As the period is T=4 sec, the

control determines in which area of the interval the heater is

ON. (Picture 5). The control has the shape of PWM signal,

that serves to turn ON and OFF the heater. In the previous

example, the steps of scaling and descaling are pretty simple.

Now we are going to explain the step of creating the LOOK_UP

table, that in fact is the base of the control algorithm itself.

Creating the Look-up table

Before we start to elaborate the creation the Look-up table,

lets imagine we already have one created. Analyzing the Look-up

table, we can notice that control can only be positive. That

means, the system can only be heated. (it cools by turning OFF

the heater). The values of uf are 1,2,3 or 4 that means in the

period of 4 sec the heater is ON for 1,2,3 or 4 sec. We can

notice that fuzzy control is much more precise then the ON/OFF

control. How more precise it is, depends, on the structure of

FLC, on the software. The procedure of achieving the values

(0,1,2,3 and 4) that are described in the Look-up table can be

understood on the basis of a help table usually called Fuzzy

Associative Memory-Picture 7.

1. IF e LN

THEN u AZ

2. IF e AZ

THEN u AZ

3. IF e LP

AND de VN THEN u LP

4. IF e LP

AND de LN THEN u LP

5. IF e LP

AND de AZ THEN u VP

6. IF e VP

THEN u VP

A comment on the rules written above: 1. and 2. do not allow

the temperature to be higher then the given one. The rules 3.

and 4. restrict not to overheat the water if the error is not

too big and there exists a tendency to achieve the given value

of temperature. Rule 5. says, if the error is not too big, but

there does not exist a tendency to achieve the given value, then

we have to heat more intensely (longer). Rule 6. says that for a

big error we have to heat with much greater intensity. In a

certain moment, there exists one fuzzy error (ef) and one fuzzy

error change (def). On the basis of picture 7, we determine the

degree of belonging of ef and def for the first rule. Later we

determine the minimum of these two values, and this way we

achieve the dashed surface. The procedure has to be repeated for

all the other rules. The surfaces we get from the calculations

have to be summed, and by one of the methods, we determine the

fuzzy controlling.

Determining the control

For calculating the fuzzy control, it is necessary to

determine the center of gravity, using the shapes determined in

the previous steps. The simplified calculation is based on the

next formula: uf=(F1*n1+...+Fk*k)/(n1+...+nk), k=1 : 6. The

analogy is certain with the calculation of center of gravity in

mechanics. For instance, if ef = 0.5 and def = - 1 then we can

see from Picture 7 that uf=(0*1+2*0.25+4*0.25)/(1+0.25+0.25)=1.

Each pair of values of e and de can be from the domain

(-4,4)X(-4,4). This way, uf can be calculated. For forming

the Look-up table, we need integers-positive and negative

(-4,-3,...,3,4). We enter the so created Look-up table into the

program that is performed by the microcontroller. There,

it is used for real time control. After we described the

procedure of creating the Look-up table, it is useful to try to

find out the possibilities for adjusting the control algorithm,

to determine the parameters upon which the FLC depends:

· Setting up the resolution of fuzzy variables (for fixed

limits of real values). The resolution that we introduced in our

example goes from - 4 to 4. There are no limits

for the values to be (-2,2) or (-10,10). In the first case, less

precise control is chosen, while in the second, we chose a more

precise control.

· The number of labels is 5 (very negative,...,very

positive). This number can be 3 or 7 or 9 etc. The smaller

number of labels supposes smaller precision, while greater

number of labels supposes more precise control.

· The function of belonging can be of different dimensions

and shapes: trapezoidal, Gaussian, triangular etc. In our

example, we used the function of belonging in a shape of

triangle.

· The number of IF...THEN rules is not fixed; it is

determined by the expert.

From the enumerated objections, we can conclude where we can

find ways to make adjustments. The understanding and mastering

of the process is of great importance for good FLC adjustment.

Before a practical use of FLC, it is desirable to perform a

simulation of control on the computer. This way we are able to

test the possible behavior of the process in the procedure of

control. The most commonly used program package for this purpose

is MATLAB.

| |

VN |

LN |

AZ |

LP |

VP |

| VN |

- |

- |

- |

- |

- |

| LN |

AZ |

AZ |

AZ |

AZ |

AZ |

| AZ |

AZ |

AZ |

AZ |

AZ |

AZ |

| LP |

LP |

LP |

VP |

- |

- |

| VP |

VP |

VP |

VP |

VP |

VP |

Table of FAM (Fuzzy

associative memory)

Picture 7. Fuzzy control determination - gravity method

The

description of a real system

The central part of FLC is a board with Motorola's

MC68HC11F1 microcontroller working on 8 MHz. On the board,

behind the controller there are included: 32 Kb of memory, power

regulator 7805, power monitor with reset circuit TL7705, and all

the necessary passive components for work. For indicating the

temperature, a 7-segment display is chosen, with 4 digits.

driven by Motorola's MC14499 circuit.

Picture of experimental system

The heater is connected to

the mains, via a tyristor, that is activated by an optocupler

with zero-crossing circuit MOC 3043. The optocupler is connected

to the zero line on port G ( PG0 ), and activates on logical

‘0’. The heater is of 150W. It serves to convert the digital

signal of PWM into the action of water heating. Next to the

heater, in the box, we have an NTC resistor, termomether and

mixer. The mixing is of extreme importance, because it reduces

the delay in the system, and guarantees a linear temperature

distribution. In this case, the temperature difference between

the top and the bottom of the vessel equals 0.2 C. We can

consider it as a very good result. The NTC resistor serves as a

measuring instrument, whose purpose is to give the information

about the instant temperature values.

Picture 8. NTC resistor

resistance/temperature dependence

For temperature

measuring, an NTC resistor of 47K, from Simens is used with a

tolerance of 10%. The label NTC (Negative Temperature

Coefficient) describes the nature of the resistor, that in

dependence of temperature change, changes its resistance. The

change can be positive-the resistance increases with temperature

increase and negative-the resistance decreases, with temperature

increase. In this case on 0 C resistance is 165.642K.

On 25 C (that is the referent one) 47K. The label 47K

describes the value of the resistor, on the referent

temperature.

Picture 9. AD conversion and real

control

The resistance

dependence can be also mathematically described the next way:

R=RO exp(b/T). RO is a constant that depends upon the material

and dimensions of the resistor, b is a coefficient of

temperature sensitivity and T is the temperature in (K). With

temperature change, the resistance of NTC changes, and the

voltage with it that is recorded on the AD converter. We

used an internal 8 bit AD converter with precision of

1LSB. For temperature displaying, it is necessary to recalculate

the voltage of NTC into temperature. There are two

possibilities. One is - using the formula, we directly calculate

the temperature. The second one is, to experimentally determine

the table that linearise the real characteristic. In our

example, we used the second method. The labels PE0 and PG0

represent the ports of the microcontroller. For instance, PE0 is

the E port (the input of the AD converter), the zero line. On

the basis of the used components, the maximal accuracy

(precision) that can be achieved is 1 C, that is usual in

temperature measuring. Using higher quality parts and AD

converters, and higher resolution, better results can be

achieved. On the other side, the costs of the entire project

increase.

Picture 10. Program execution diagram

The procedure of control is the next: the referent value is

given, and in periodical time intervals (sampling rate is 4 sec)

a digitalized information of the instant value of temperature is

acquired. After that, we calculate the error and error change.

Using these (previously scaled) from the Look-up table, we read

the scaled value of control (from 0 to 4) that after this are

descaled and as such, represent the interval during which

the heater is turned ON. The job of the microcontroller is to

insure that the heater will be ON as long as it is calculated.

On Picture 10, a block diagram of the described control

system is shown.

|

unsigned

char LOOK_UP[9][9]={{0, 0, 0, 0, 0, 0, 0, 0, 0 },

- {0, 0, 0,

0, 0, 0, 0, 0, 0 },

- {0, 0, 0,

0, 0, 0, 0, 0, 0 },

- {0, 0, 0,

0, 0, 0, 0, 0, 0 },

- {0, 0, 0,

0, 0, 0, 0, 0, 0 },

- {1, 1, 1,

2, 2, 2, 2, 2, 1 },

- {2, 2, 2,

3, 4, 4, 3, 4, 4 },

- {3, 3, 3,

3, 4, 4, 4, 4, 4 },

- {4, 4, 4,

4, 4, 4, 4, 4, 4 }};

- unsigned

char REF,TEMP, ERRMAX,DERRMAX, FUPR;

- unsigned

int ITIME, TIME_ON,T, PRIV;

- unsigned

char C1,C2,ISPISI,UPRMAX;

- signed

char ERR,ERR2,FERR,DERR,FDERR;

|

Listing 1.

Program fazi1.c

|

static void

interrupt intr(void)

- {

- ITIME=ITIME+1;

- ADCTL=0;

- do{}while(ADCTL

!=0x80);

- PRIV=PRIV+ADR1;

- if(ITIME==T)

- {

- if(TIME_ON!=0)

PORTG=0; /* T=4s*/

- PRIV=PRIV/244;

- TEMP=(unsigned

char)(PRIV);

- PRIV=0;

- DERR=(signed

char)(ERR-ERR2); FERR=4*ERR/ERRMAX;

- FDERR=4*DERR/DERRMAX;

- FUPR=LOOK_UP[FERR+4][FDERR+4];

- TIME_ON=FUPR*UPRMAX/4;

- ERR2=ERR;

- ITIME=0;

- }

-

- if (ITIME==TIME_ON)

PORTG=0xFF;

-

- TFLG2=0x40;

- }

|

Listing 2.

Program fazi2.c

|

main()

- {

- PRIV=0;

- ITIME=0;

- REF=114;

- T=244;

- UPRMAX=T;

- TIME_ON=0;

- OPTION=0x80;

- ADCTL=0;

- do{}while(ADCTL

!=0x80);

- ERRMAX=ADR1-REF;

- ERR2=ERRMAX;

- DERRMAX=ERRMAX/5;

- PORTD=0x2F;

- DDRD=0x38;

- SPCR=0x5C;

- DDRG=0xFF;

- PORTG=0xFF;

- PACTL=0x02;

- TMSK2=0x40;

- TFLG2=0x40;

- di();

- set_vector((isr

*)0xFFF0,intr);

- ei();

- for(;;)

- {

- Konvertuj(TEMP);

- Ispisi();

- }

- }

|

Listing 3.

Program fazi3.c

The control algorithm is placed in the interrupt routine, and

activates each 16.384 ms. To adjust the sampling period of 4 s,

we need around 244 RTI interrupts. When the working time of the

heater is calculated (0<TIME_ON<4) it is necessary to

ensure turning OFF of the heater, after the elapsing of the time

interval. This way generating a PWM signal with a 4 s period,

that represents the control. On listing 1, variables used in the

program are declared, and the initialization of the Look-up

table is done. Listing 2 represents RTI ( Real Time

Interrupt) the interrupt routine, in which the results of the AD

conversion are processed and the times of turning ON of the

heater are calculated. In the interval of 4 seconds, the program

enters 244 times the interrupt routine, and each time the value

from the AD converter is red. Their total sum (PRIV) after 4

s elapse, is devided by 244, this way very regular temperature

readings are accomplished. Calculating the medium values, we can

achieve more precise results and we can reduce the influence of

noise. Listing 3 is the main program. In the first part, we

initialize the variables that appear in the program, SPI

communication and RTI interrupt are declared. In the

closed-loop, there are only two functions. The first one

performs the conversion of temperature from binary into decimal

values (necessary for the display) and the second function sends

the decimal ciphers of the instant temperature values trough SPI

communications.

Comments on Results

Before the implementation of the control algorithm on a

system, we performed a simulation. The simulation is performed

on the bases of the law of energy transformation. The

transformation of electrical energy into heat can be described

with next equation: P*dt=m*c*dT. P=150W, heater power, dt is the

heater working time, m=0.4 kg mass of water, c=4186J/Kg*K,

specific heat capacity of water and dT is the change of water

temperature as a result of heating. After the simulation, the

control algorithm is tested on a real system. Each 4 sec the

values red from the AD converter are stored in the external RAM

and after that, this value is transferred by serial

communication to the computer, where the data are processed.

Picture 11.simulated results of the

system with Look-up table

Picture 12.real results of the

system

Comparing the simulated and achieved real results of the system,

we can notice a large degree of similarity. The difference

between the simulated and real system, appears as a result of

noise in the system, and as the impossibility to simulate the

entire real system completely. Instead of conclusion, we offer

the answer to the question why fuzzy controllers are convenient

for automation engineers? They describe the solution without

complex mathematical model of the system.

· Optimizes the already existing solutions, with the purpose

to achieve a more simple and efficient end product

· Reduces the price of the end product on the bases of

simplified procedure of modeling

· Clarifies the system. System is understandable, easier for

maintenance and upgrading

· Higher resistance to errors and changes of the system

environment

· Increases the system robustness without decreasing its

sensitivity

On the bases of the performed experiments, we can conclude

that fuzzy logic controllers are applicable in the problems of

temperature regulation. We can not give a final mark about the

possibilities and quality, because the system was not tested in

the conditions of disturbances, nor compared with other control

algorithms (from which the PID regulator is the typical

representative).

autors:

Stevan Tošić

dipl. eng. & Nebojša

Matić

translated by:

Simeon

Todoran

|