Suzy

My First Micro-Sumo:

What you see on these pages is a work-in-progress.

Each page is another step in idea or construction methods towards the

"finished" sumo.

If you have any comments or suggestions, please feel free to send an

email

or say "Hi" at the Portland Oregon PARTS meetings.

Paul T Barton.  <= This is a graphic you can't click it.

<= This is a graphic you can't click it.

Page Two:

Page Three: 'Pushy' (at bottom)

Page Four:

Page Five:

Page Six: 'PolyCarb'

Mini-Sumo 'Bots

Downloadable Code:

PIC Assembly (MPlab 7.41 IDE).

ExpressSCH: Schematics,

also shows the "nano" pcb.

Nano Stuff: Kinda

dup of above page...

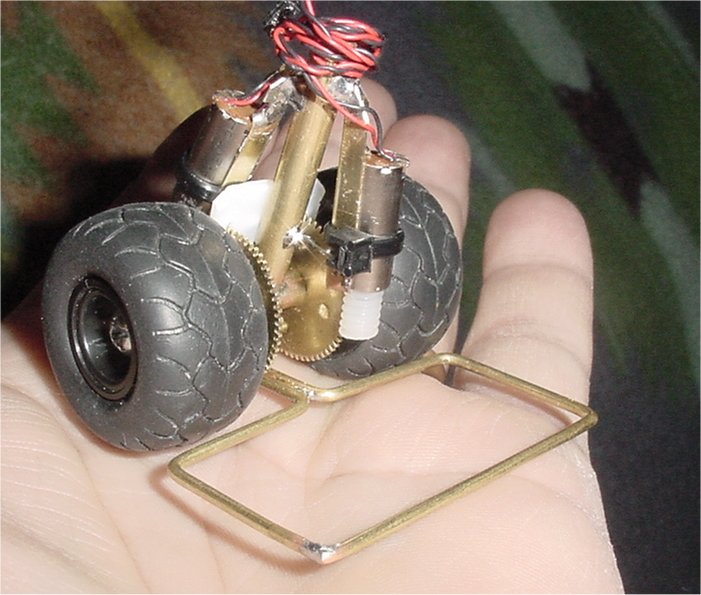

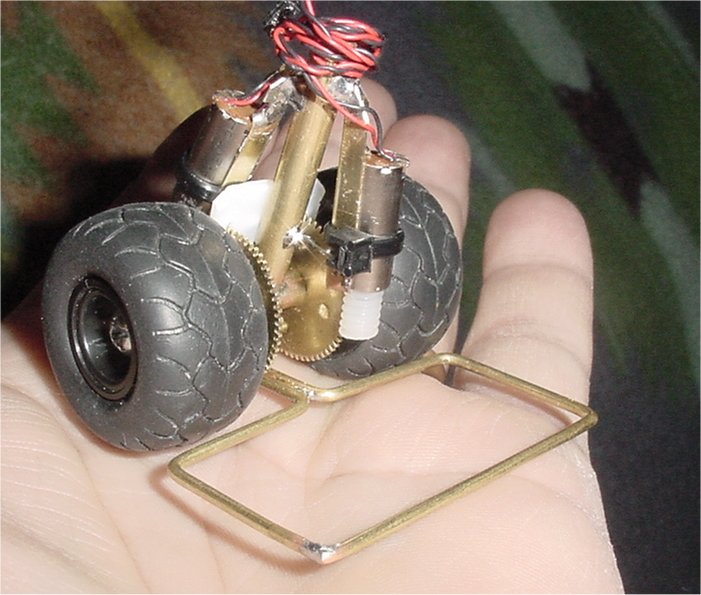

Front-quarter view.

Two pager-motors with added worm drive.(PDX Wacky Willy's, $2.50) Motor

shafts are 0.97mm diameter.

Tandy ZipZap(r) Truck tires from the upgrade kit ($2.97).

Brass gears from 1/3 RPM AC motors. (Wacky's; $0.60 / 4 gears per motor

= $0.15)

For now it weighs 1.2oz. Plan to drill holes to lighten it up.

MCU:

I plan to use PIC-16LF84A-04 mcu's with double-stacked 74AC245's wired

as motor drivers, BEAM like.

This way there's control of forward, backward or shorted per motor

and floating (disconnected).

Has FET to change CPU clock speed.

---

Yes, It's too big for micro-sumo, but it will be used for testing only.

Rear View.

Shows spacing between gears. Micro-Sumo size is 1 31/32" (approximately).

Motor is laying in brass-angle with a cable-tie to hold it still.

Parts of that angle are bent up just enough to hold the motor from

sliding.

Right Wheel Gear View.

Shows close-up of worm-drive.

Worm gears are 10-32 nylon screws with a hole drilled up the center

then cut to length.

Hey ... it works.

Brass gears have 60 teeth which gives an approximate final ratio of

60:1.

The gear is up against the frame-tube (5/32") and it looks like it's

attached but not so, just touching.

Hobby brass tubing; 1/8" inside of gears. Soldered on wheel side.

Worm-gears can't be pushed and back-turn the motor.

Right Motor View.

Here you can see the end of that brass angle and how it's bent up slightly.

Also, shows what keeps the wheel-gear assemblies attached to the frame,

that notched plastic piece.

Each wheel is screwed to a hex-brass PC-mobo mtg

piece. It can be seen just barely inside of the right wheel, the hex end.

To the ground-down threaded portion is 1/8" brass

tubing soldered on.

To the end of this tube is the gear, soldered on

the inside.

The stub of the brass tube goes half-way inside

of the frame tube seem here in a "T" configuration.

The screwed-down plastic piece keeps the wheel+gear

assembly from sliding out. It can't slide in as the gear stops it.

Sue and I

This page updated: July 20, 2006.

Paul T Barton.