|

|

|

| Project duration |

1997-1998

OPTIMA GmbH, AUSTRIA |

| Project tasks |

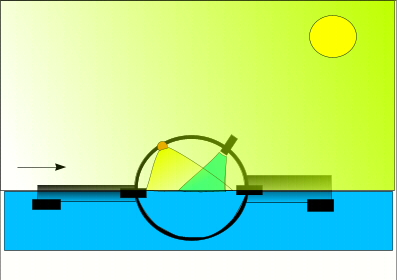

Golden Eye is created to

recognize oil spots on water surface by monitoring with CCD camera. A

special enlightenment and geometrical location of the CCD camera in a closed

dark box make possible the recognition of objects, floating on water

surface. |

Description |

Oil in water

|

The oil spots on water surface are difficult

to be recognized because the oil is spread in a very thin layer and the

colors of water and oil are very similar. Golden Eye uses a perfect method

for enhanced separation of objects using their intensity. The proper

geometrical location of the camera in the black box and the highly sensitive

algorithm facilitate the distinguishing of oil spots from water surface

(background) and visualize them on the computer screen. As a result Golden

Eye shows the surface of oil spots as a percent from the total surface. |

|

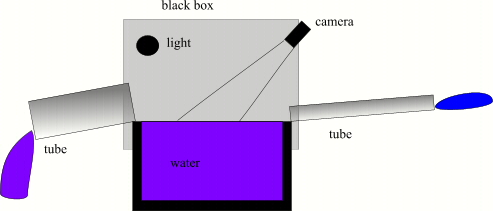

In case of fast running water a potential difference between

the two tubes is necessary.

If the water runs not so fast it is possible to use a

floating configuration. The most important thing is to avoid

waves. |

HARDWARE INSTALLATION

The hardware is a system consisting of a black

box, two tubes, a CCD camera and light source. The construction protects the water

surface from the sun light and the use of a special geometrical location for

the light source makes possible the recognition of oil spots. A special

system holds the distance between the water surface and the camera

so that a good picture can be obtained without fixing the focus

every time. It is very important that the water surface is calm at the point

of measuring.

|

SOFTWARE

The programme was created in VisualBasic 6

programming language and uses MATROX graphic card driver system (MATROX

METEOR).This determines some hardware requirements.

To start using Matrox Meteor you need the

following:

Minimum requirements :

- For full Matrox Meteor functionality we recommend

system that uses newer PCI chipsets, such as the Intel 430FX, 430HX, 430VX

(Triton) PCI chipset because they generally offer the required

sustained capability.

- For a Pentium Pro system with a 440FX chipset you must

use a Matrox Meteor /ppb; other versions will not work. In addition, when

using this chipset, the colour grabber might be limited to 5:5:5 (15 bit)

format because of system memory bandwidth limitation.

- For more information please use Matrox Meteor

(Installation and hardware Reference book) 1997.

The programme does not use all the power of the graphic

card. Golden Eye uses only one channel from the graphic card in CCIR

(Initial digitizer configuration format). The so programmed set-up gives

black and white signal in the area of 768x576 points. The Golden Eye

processes in a half of this field.

Golden Eye Menus

Golden Eye is a completed package. It compiles to EXE

code, which uses the MATROX METEOR functions created on C++ and converted to

DLL databases to take the picture from the CCD camera. Golden Eye uses

Windows 95 or Windows NT and is distributed on 3 diskettes (Set-up disks).

One additional disk contains instructions and the necessary information

about the system installation and the system set-up. After set-up

installation you can start Golden Eye from your desktop (the programme menu

on your computer). |

|

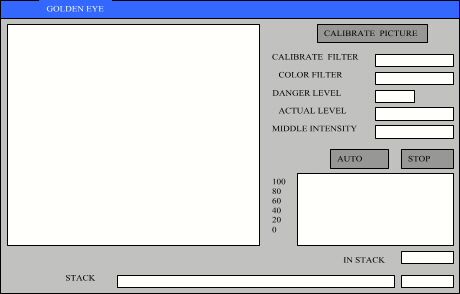

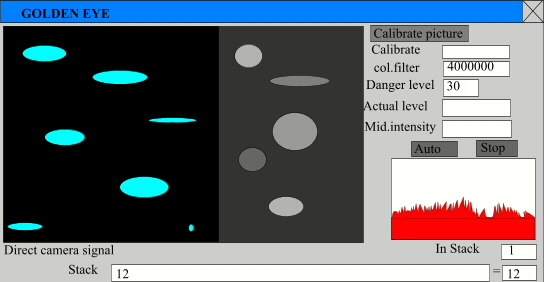

Fig.1General panel

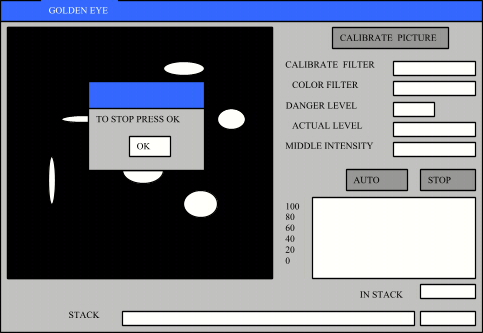

Fig. 2 Hardware calibration

process

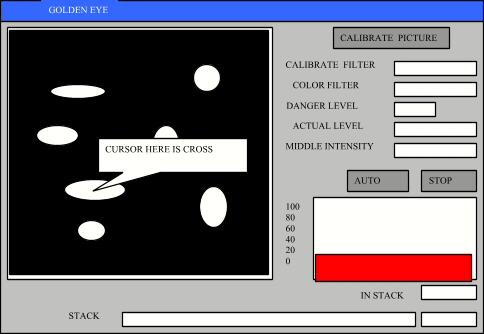

Fig. 3 Obtaining figure for

proper filter

Fig. 4 Example for good

calculation-See Picture Box

|

At starting Golden Eye on your screen for

some seconds an advertisement page appears and the programme displays its

general panel (figure 1) on your screen.

This panel contains Big Picture Box with information from

the camera, three buttons (Calibrate Picture, Auto and Stop), the graphical

box with scale (0-100%) and some other fields which will be described below.

The picture box will be blank. Now you are ready to

start Golden Eye. You can start or stop the data calculation with AUTO and

STOP buttons. You can press STOP button any time when you want to stop and

calibrate the system. Press AUTO to start the Golden Eye. In order to

obtain good results you need to calibrate the color filter. If the color

filter is not correctly set in the COLOUR FILTER BOX, the result will

be wrong.

How to set the filter

color?

Golden Eye has an automated function for obtaining the

light intensity of any point. If you have just started the system, then the

color filter in the box has value 4 000 000. This is the automatically loaded

filter, but probably it is not the proper one for your case. The cursor in

your Picture Box becomes a cross (Fig. 3) and if you click the mouse upon any

point of the Picture Box in the Calibrate Filter field you will obtain the

value (intensity of this point in the range between 0 and 16 777 215, 0 is

black). Press AUTO and then click the mouse on some spot in the Picture Box

screen. So you will obtain the intensity of this point in the CALIBRATE

FILTER box. Now click the mouse on some point of the background and you will

obtain the value for the background intensity. The value that you should

choose for your filter must be between these two values. Write down in the

COLOUR BOX some value in this interval. After some probes you will obtain a

filter value, which is proper for the Golden Eye and the program will

calculate the surface of the spots correctly (Fig. 4).

Protection from false alarm?

The result depends strongly on the picture, taken in an

instant. It is not recommended to draw conclusions based on such

short interval of time. That?s why it is good to make a conclusion based on

the processing of several pictures, taking into account the average value.

This is the only way to protect the programme from producing a false alarm

signal. That?s why Golden Eye saves the data from several pictures in its

memory and the final result is their average. STACK is the

place when Golden Eyes saves the data and the average value will be used for

comparison with the Danger Level. How many values you want to have in

STACK depends on the operator. Golden Eye enables you to keep and compare

data in the range of 1 to 50 units. |

|

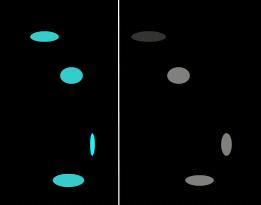

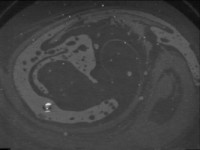

Fig.5 a) and b)

|

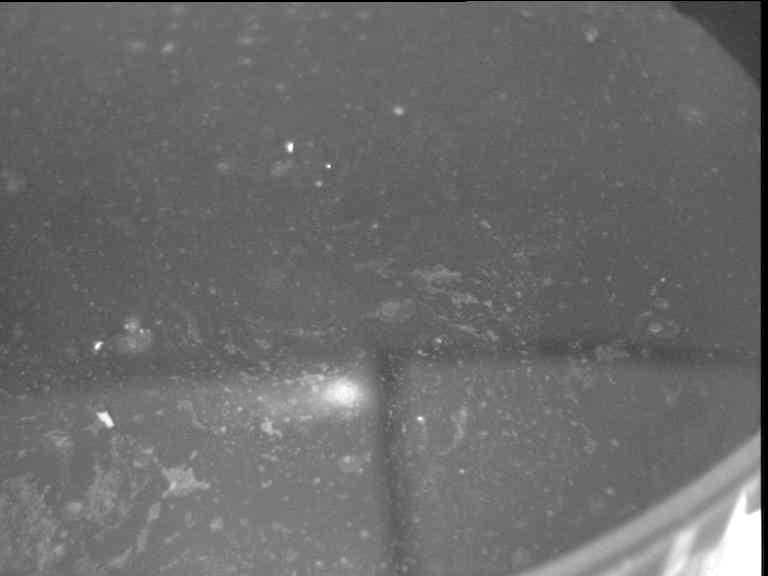

Some examples on object processing.

What does exactly appear in the Picture Box

before and after calculation you can see on Fig. 5a and 5b. Picture 5b shows

the intensity of oil spots before calculation. With a naked eye can be seen

three spots. After calculation Golden Eye colors the oil spots in light blue

(Fig.5a) upon black background. How exactly Golden Eye processes the

objects, depends on many factors, as correct filter, proper position of the

camera and light, proper focus, water situation, water velocity, ets).

|

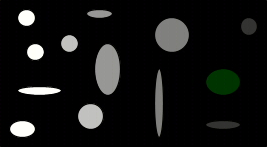

| |

Fig. 6 (Incorrect filter)

|

Figure 6 is an example of a picture, made by

incorrectly set filter. The spot is not well outlined. In this case

a higher value should be given for the filter.

|

| |

Fig.7

|

In this case ( Fig. 7) the light source is

incorrect and the spots are not equally illuminated. |

| |

Fig.8

|

On Fig. 8 a uncommon object is visible on

the background (probably some reflection from water surface). In this case

you must be very careful and make Golden Eye calculate this object as

background. This is not a spot and therefore Golden Eye must calculate it

as background (or color it in black) |

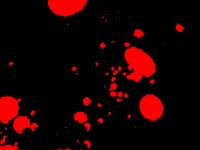

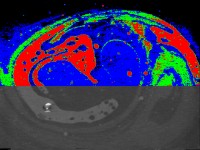

| |

NOT calculated from system real picture

Calculated form system picture ( the spots are in red)

Half of picture is calculated

On the last picture you can see two kinds of oil spots

(calculated in red and green) and water surface in blue |

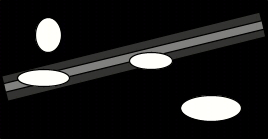

Some real pictures

|

| |

New interests for oil in water recognition

|

|

| Year 2000 |

is still interesting for the industry.During 2000 new experiments were

prepared and new set up for testing new software

approaches for oil on water recognition was built. The experiments were carried out in

City University - London UK.

is still interesting for the industry.During 2000 new experiments were

prepared and new set up for testing new software

approaches for oil on water recognition was built. The experiments were carried out in

City University - London UK.

|

Many industrial partners are

involved in this environment protection project. The big challenge in the

future will be tracking, recognition and analyzing oil spots in water with real

time systems. There are many other techniques for oil in water recognition

but image processing is one of the best approaches without moving parts, not

expensive, not high energy consuming and very suitable for automation. This

makes our approach very promising. |