|

(2003-2005) EC sponsored research and development project

OBJECTIVES

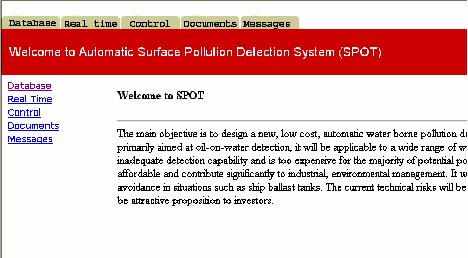

The main objective was to design a new, low cost, automatic water borne pollution detector of a general-purpose nature. Whilst it is primarily aimed at oil-on-water detection, it is applicable to a wide range of water pollution problems.

The proposed system is affordable and contribute significantly to industrial, environmental management. It also makes a substantial contribution to disaster avoidance in situations such as ship ballast tanks.

RESULTS

We proposed new physical approach for enhanced separating oil on water. It is based on fluorescence response of the oil spots. This method reduces significantly the mathematical calculation for oil extraction by minimising the ratio signal/noise in the captured frame.

The system (using UV source 1W light power) for monitoring area of 45 sq. cm has been developed and tested. It uses synchronous capturing method and can be powered from battery and operated remotely by transferring visual data via radio frequency (wireless connection) to internet server.

New mathematical algorithms have been developed and applied for continuous capturing and calculating of the water pollution. They allow extracting of different parameters and create possibilities for further experimenting. Some of these features extracted from the physical behaviour of the oil spots (shape of the oil spots, activity of the spots, intensity and size) can be used for further pollution assessment such as finding out the time since the pollution has occurred and the type of the pollutant.

This method reduces significantly the mathematical calculation for oil extraction by minimising the ratio signal/noise in the captured frame.

Real prototype based on this approatch has been built. It is functioning as independent floating construction in the water. All controls and data visualisation is done on the ground computer. Whireless connection supports this communication. Internet server allows transfer of all data via internet to remote users.

The prototype

The prototype has been built in two separate stages.

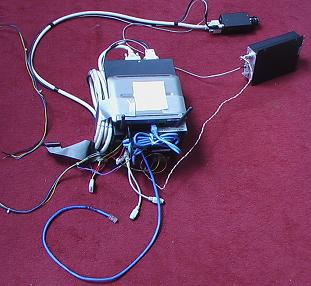

The first one is the pod which accomodates the image capturing equipment and the wireless connection.

The pod has been built on the results of inital laboratory experiments for geometrical positioning of the

light source and the camera. All equipment in the pod is powered from single 12V battery.

The consumption is minimised by using state of art equipment (light source and image processing design) based on sincronised impulse capturing. Such system consumes much less energy than continious capturing system and

allows long live for the battery.

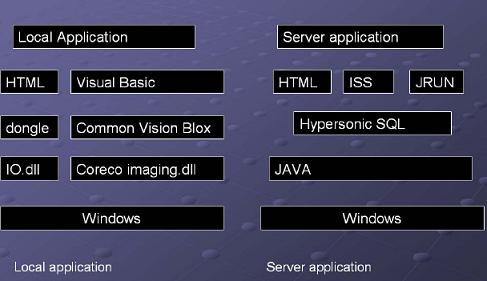

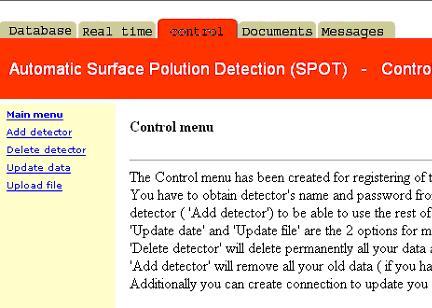

The second stage is building the software. The software is based on C++ and VB application which captures the data from the

camera, sinchronises the light source, calculates the polution level and transfers the information to the server via wireless connection.

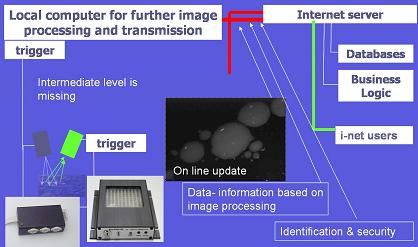

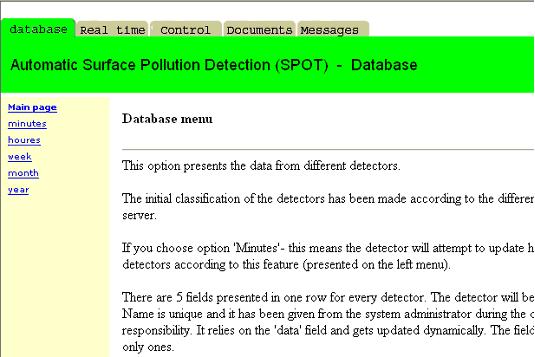

The server is based on Java and Hypersonic SQL and implements 3 tiers. Client tier based on HTML, bussiness logic tier based on Java (servlets and JSP) for dynamic update

of data representation and final tier which is the Hypersonic SQL database. The client can collect data, view real pictures of the pollution every 3 seconds and view on-line graphs of the pollution. The server can support 10 detectors at the same time.

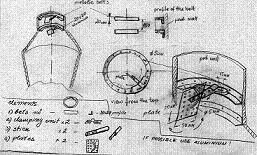

You can see different stages of hardware and software building process starting from my simple sketch and the idea for possible fluorescence respond of the oil.

| Hardware | | Software |

Here is my simple sketch. | |

This is overal software design |

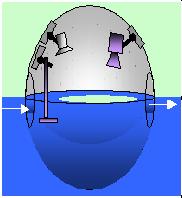

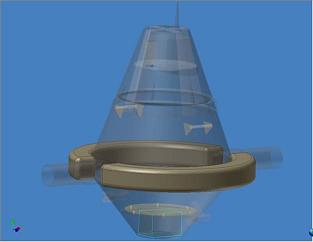

This is the computer model of the overal design | |  |

Design of the main pod construction | |

Here you can see superimpose the picture from the camera and the calculated oil (in the patch)after image processing |

Main pod | |

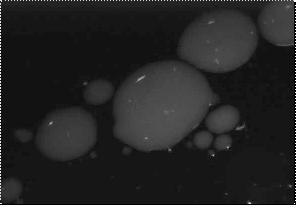

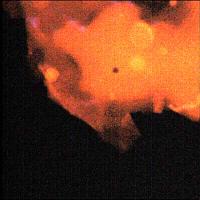

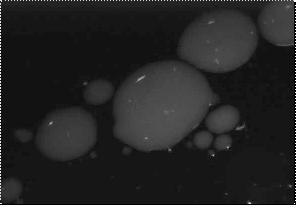

This is fluorescent response from drop of pure petrol. The picture is obtained from 5 cm sq surface at 1 meter distance . |

Design of the hardware in the pod. You can see the computer and the image capturing equipment (camera and UV light source). Also the power supply cables are visible.The network hub is on the top of the computer.The cable between the light source and the camera is the synchronisation. All equipment here is designed to be powered from a battery. | |

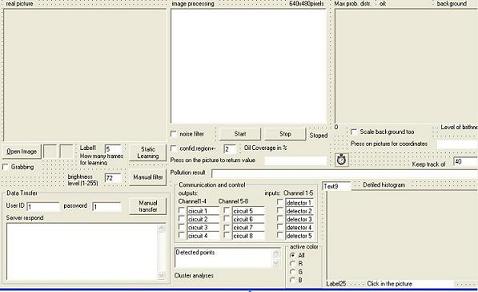

GUI of the application for image processing of the embedded computer in the pod (VB, HTML, C++) |

Finally the parallel port extention is attached (in front of the wireless hub). This box allows the control of external devices using software via wireless connection. | |

This is part of the server application. This is full 3 tiers application with SQL databases and dynamic update of the visual input from the camera. Also it maintaines the user password and the wireless connection |

This is CAD animation of the final design of the system with floats in the water. | |

|

Finally CAD glass model. | |

|

Main results

The main results have been published. They are:

new physics approach to the problem of oil pollution in the water

new algorithms for image processing of colour images. Based on this the system can

recognise not only the existance of oil in the water, but also the type of the oil. This is important for identification of the exact source of the pollution.

The picture bellow is obtained from our experimental model using black and white camera. This system is capable to transfer one frame every 3 seconds to the final client . This is the done using image processing in the pod,then transfer via wireless connection to the server and then via internet transfer to the final client).

You can see fluorescence response of the oil spelt on 5 cm sq.

The following pictures are from the last test of the prototype.

On the second picture you can see the monitor for the local application

(embedded computer)and the server application.

Because the unit is independent in the water only the server monitor is on.

RELEVANCE FOR THE SOCIETY

Industrial needs for monitoring are found in oil-produced water, process water, non-contacting cooling water, ship ballast water, industrial wastewater, hydroelectric water, storm water, municipal wastewater, potable water and recreational water.

The system, suitable for continuous monitoring (several days), prediction and statistical measurement also creates possibilities for unique early detection alarm.

The project aims at detecting and thus reducing the presence of hydrocarbons and other toxic and explosive substances in industrial wastewaters and other water collecting systems. Water protection is of great strategic concern for the EU.

The activities in the project contribute to the development and implementation of several European Union policies. It primarily supports EU policies regarding environment and industry.

My personal involvment

As leading researcher I have been responsible for all experimental and scientific work done in this project.

I have built the local application and image processing algorithms based on C++ (low level) and VB (high level GUI).

I have designed the server application and communication protocols between the pod and the server.

I designed and implemented the server in three tier approach based on Java, HTML, Hypersonic SQL,JavaScript.

This includes all business logic in the server as dynamic rendering and graphical data visualisation.

I also have been involved in the production of the technical documentation and results publishing.

PARTNERS:

METALURGICAS NALES, S.A.

ALPHALAS GMBH,D

PARTECH LIMITED, UK

OCEANGRAPHIC COMPANY OF NORWAY ASA, NO

ALAN WHITE DESIGN,UK

BCB INFORMATICA Y CONTROL, S.L. ,ES

RTDs:

UNIVERSIDAD POLITÉCNICA DE MADRID-DISAM,ES

CITY UNIVERSITY LONDON,UK

|